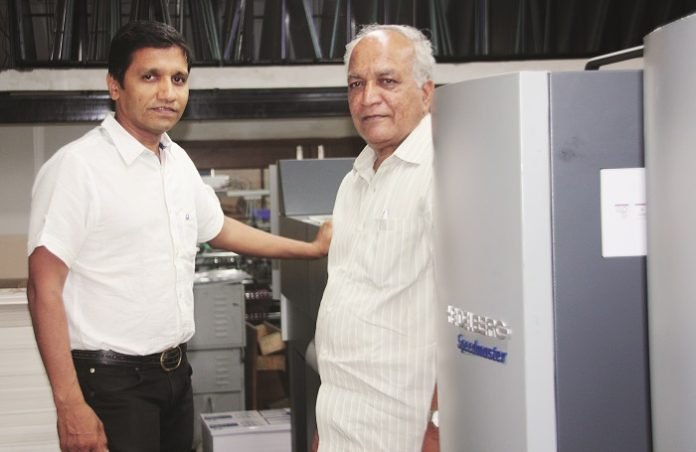

In a bid to improve core competency, Pune-based Sudarshan Arts upgraded its unit with an automatic high-pile delivery configuration—a 4-color SM 74 press. Speaking to Indian Printer and Publisher, Sudarshan Bhutada, director of the company, says, “We found the press flexible for processing of different production run lengths, both for commercial as well as packaging printing. The Speedmaster SM 74 is ideal for print shops to meet the rising demands of the customers, fuelling the growth in a changed market environment. The makeready time is short with a print speed of 15,000 sph. It’s the perfect blend of convenience and better productivity. Since the installation of the press, we have been running all our major jobs on this machine, sparing the 6-colour press that we have for other complex jobs.”

Having used a 6-color Heidelberg SM 102 press, Bhutada already had confidence in the Heidelberg press, and the need for a high pile delivery was another reason to go for the SM 74 press. The delivery unit is equipped with both a touchscreen and jog wheel for ease of use and efficiency. In a touchscreen based high-pile delivery unit, the sheet travels a longer distance from the impression cylinder guided by a sheet guide plate with venturi nozzle air system without smearing or scratching of ink. The Speedmaster SM 74 processes a wide range of substrates—from 0.03 mm in thickness of lightweight paper to 0.6 mm thickness in a board. It also benefits from extremely user-friendly and ergonomic operation. The Prinect Press Center Compact with its innovative software “Intellistart” process-oriented operator guidance system enables fast changeover between jobs. The software package “Color fast solution” allows quick inking unit reaction and reduces wastage to a minimum level. The feeder with suction tape, which is unique in its class, optimizes sheet transport. Automation components such as AutoPlate or automatic, programmable washup devices minimize make-ready times. The proven “alcolor” dampening system with alcolor vario enhances the print quality and removes hickeys on the fly.

The high energy and resource efficiency of the Speedmaster SM 74 makes it the most environment friendly press in its class. Star System peripherals perfectly coordinated with the press benefit from the highly efficient operation and conserve resources. “We have a production schedule which is in a continuous flow. Prinect has helped us prepare the next job while one is being processed; the high pile and delivery mean we don’t need to stop the press for feeding new stock,” he adds.

While the Prinect has automated processes, manages data and creates a condition for efficient production, the 1-meter height high pile has allowed the company to print long-run jobs with ease. For maintaining the quality and service needs of the existing clients for commercial and packaging jobs, Sudharshan Arts turned to the SM 74, which allows a maximum paper size of 20 x 29 inch. Apart from outsourcing the prepress needs of the plate, Sudarshan’s other equipment include a Boxtech among foldergluers and finishing machines.