Estimates of Indian newspapers that are actually in print vary widely. There are reports of as many as 70,000 to 90,000 publications although these are surely exaggerated – the numbers likely contain not only newspapers but all kinds of periodicals that may at one time have been registered with the authorities. Global observers marvel at the fact that 43% of the advertising spend in India still goes to print. However, they may not be aware that this number was as high as 49 or 50% just a decade ago.

Nevertheless, some estimates put the newspaper industry growth at 8% in the past year which is not really very high considering a GDP growth of approximately 7.5%. Another catch is that while 8% represents the overall growth of the industry it is dominated by the leading publishing groups with significant stagnation amongst many of the medium and smaller papers. It is clear that the top 50 or 100 or even 200 newspapers are growing but the individual rates of growth are no longer astronomical and in many cases not even healthy.

There is no question that television, radio, outdoor advertising and the internet and digital media are eating into the overall advertising pie. At the same time, advertising spend still constitutes only about 0.35% of India’s US$ 2 trillion GDP, compared with 1.5 to 2% in the rest of the world. Leading publishers still see significant headroom for advertising growth and are fully engaged in opening up advertising revenues in online media. In many ways publishers are leveraging the country’s democratic dividend by encouraging engagement using the new interactive digital channels. Most sections of the increasingly literate population have no choice but to be aware of and to take part in both local and national politics and the publishers in India know how to feed this hunger for livelihood, development and administrative and economic reform.

Moreover, the Indian newspaper publishers are still beneficiaries of government munificence both in terms of government and public sector advertising and by laws allowing them to continue to own multiple media channels. There is no law preventing publishers from entering any language or geographic market while they are protected from global media companies coming in. Many publishers own television and radio channels and have made large investments in digital media channels and assets.

The high proportion of young people in the population or the demographic dividend presents a huge opportunity to build commercially viable models with the Indian audiences at its core. This audience wants to consume news wherever they are on multiple devices and it prefers short form to long form stories. This audience now depends on social media for breaking news. Newsrooms that hold stories for print are obsolete.

Indian dailies are both innovative and efficient

Indian dailies have innovated both editorially and in their production. They have been forced to innovate and have transformed their entire product to full color realizing early that their main cost was newsprint. It makes business sense to double revenues by simply adding more production value to your biggest input. Innovations include all kinds of special flaps and half covers and panorama pages with the use of inline gluing. The use of gluing and UV curing allows them to produce glossy magazine supplements that are trimmed in an in-line process. These techniques allow production of extra half page front covers and pages. They can add pages in smaller multiples for increased last minute editorial or advertising with increased visibility and lower consumption of newsprint.

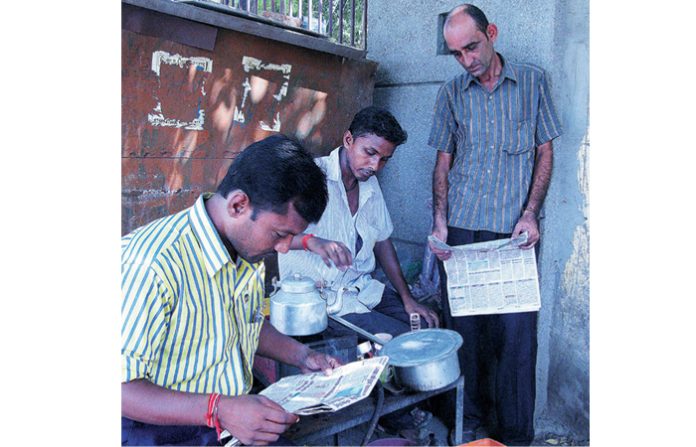

Indian dailies are also extremely cost conscious because they sell at a price that is often Rs. 150 (US$ 2) for a monthly subscription. They have been able to maintain this with a lop-sided advertising revenue based model because of continuous modernization and improvement of their processes. Newsprint, ink and litho plate savings are calculated minutely while maintaining strong localization by the production of multiple district editions on each press every night.

Newspaper printers in India continue to improve color quality using techniques such as FM screening and are perhaps the largest national contingent in the IFRA Color Quality Club. They are also increasingly using locally manufactured mailroom equipment and other AGVs to move reels and reel cores from the stores to the new automated presses. Another move to efficiency is the increased use of a common contract printing plant by several newspapers and in some cases publishers themselves doing jobwork or printing a competitor’s paper.

Indian dailies are green

The Indian newspapers are consciously reducing their carbon footprint by becoming greener and they are generally able to turn their sustainability efforts into some kind of cost control or saving such as their use of process-less and reduced chemistry litho plates. Most if not all of the major newspaper publishers use water-harvesting (which is in any case compulsory in several states). Some of the new buildings and plants of Indian publishers are designed as green buildings while others have solar panels and windmills and yet others are connected to windfarms. The use of lower grammage newsprint and increased use of recycled newsprint together with vegetable oil based inks is also part of this strong trend.

Bennet-Coleman’s green and sustainability efforts

For Bennet-Coleman the publishers of The Times of India and the Economic Times and several other dailies including Ei Samay and Vijay Karnataka, environmental concerns are pro-actively pursued and turned into action. Since 2008, its Continuous Improvement Groups have been helping the company lead the industry in this area by measuring and documenting the company’s consumption of newsprint, ink, water, energy and other inputs. In these years the group has been able to engender continuous improvement at its more than 30 print sites by reducing wastage through process efficiencies.

While eight years ago the group used only 45 gsm newsprint, it has over the years moved a considerable part of that consumption first to 42 gsm newsprint and then progressively to 40 gsm newsprint. It is not so easy to reduce grammage or newsprint quality when there is a large requirement of producing a complete section with high quality color on all pages at speeds of 70,000 to 80,000 copies an hour. Nevertheless the group has been able to continuously increase the proportion of recycled newsprint consumed. In cooperation with the newsprint suppliers it tries to reduce the losses due to reel wrapping and reel remainders and cores.

Bennet-Coleman has also decreased its ink consumption by improving the mileage by a small but measurable percentage over the past several years. Vegetable oil based inks are being tried as a substitute for traditional mineral oil based inks in keeping with the awareness that is spreading throughout the society and the advertising and government agencies for safer inputs and products.

All of the company’s printing plants have water harvesting systems together with programmes to expand the landscape vegetation. At the same time the group has started using more and more environmentally friendly plates that use less chemistry with several plants now completely using low chemistry plates.

On the energy front, the Bennet-Coleman Group has been able to control its annual consumption growth to less than 2% in terms of cost. This amounts to an impressive reduction or control in energy inputs, if one takes into account that the price of electricity has risen each year by perhaps 3 to 5%. All the plants of the company undergo environment and energy audits conducted by the internal CIG teams as well by outside agencies such as TERI.

“History is history. I only care about what’s coming next.” – Vineet Jain

“The growth of digital has altered the nature of media, and has challenged norms of what it should be. We are fortunate in India to have visibility into global trends, which allows us to proactively address them. We continue to innovate in print and television media, which drives their growth in circulation, viewership, and revenues. And we’re aggressively building a digital media business that over time could become larger than our more mature businesses.

“The newspapers in the West were dying. I felt that the same fate would befall India; maybe not for 10 years or more, but eventually. Therefore, we would have to establish a big Internet company. We invested at the beginning. Also, the digital medium is interactive, and the newspaper is a one-way, passive medium. Interactive media always wins over passive media. . . . I tell our journalists to get on Twitter and Facebook, to experience the gap between what they think is a good story and what people are reading.”