From 23 to 26 February 2015, the Hunkeler Innovationdays will be held for the 11th time at the Messe Lucerne exhibition facility. With each successive Innovationdays, the event has enhanced its international reputation. Despite this growth, the Hunkeler Innovationdays has retained its compact scope, so the event provides a deep and complete industry overview. The event is focused on integrated total solutions and practical applications, so visitors become acquainted with the latest developments in all areas of production and finishing processes for digitally manufactured printed products.

Innovationdays 2015 has grown and with 80 exhibitors it will occupy the two new halls at the Allmend centre. The additional space will enable the holding of the DOXNET conference on site rather than at the Transportation Museum as was done earlier. With prepress, print and finishing, consumables and software all under one roof, over 40 innovative production solutions are expected to be shown at the event. Digital printing offers the possibility of dynamic or personalized communication. While the last show in 2013 reflected the increasing use of webfed high-speed digital print for book production, one expects the 2015 event to also display automation solutions in transactional documents and direct promotional mail.

Dynamic finishing

Increasingly Hunkeler as a vendor of in-line paper processing and document handling and finishing equipment and technology has also made its equipment modules capable of dynamic or individualized finishing features. Now it is possible to change the perforation on each document as it moves through the in-line finishing process while Hunkeler’s laser module offers the opportunity to dynamically create digital signatures and security marks. Interestingly, the laser module can also kiss cut pressure-sensitive label stock.

Hunkeler equipment is shown at its own stand and also in-line to those of the digital press vendors. All exhibitors have to use at least one Hunkeler module but competitors such as Muller Martini, Kern, CMC and IBIS are also prominent at the show either with their own stands or in collaboration with major digital press vendors. Muller Martini will again show new digital finishing solutions for saddle stitching and perfect binding.

IBIS Smart-binder SB-3

IBIS will show its latest Smart-binder SB-3 ‘Plus HS’ on the Canon stand, running in-line with a high-speed continuous-feed inkjet printer and web cutter. Two innovative new Smartbinder features have been developed in response to customer demand to run variable-data jobs with dynamic booklet thickness or the number of pages changing continually. These will be shown for the first time at Lucerne. The first is the ASA-100 Automated Stitch Adjust system which enables the Smart-binder stitcher to continually and automatically adjust the wire staples to suit the thickness of each booklet being stitched. This system has been created to handle complex, variable-data jobs in which the number of pages in the booklets is constantly and changing. The Smartbinder SB-3’s unique and patented ISG cold-glue process, as a high-quality binding alternative to wire stitching will also be demonstrated.

The IBIS SBS-100 Sheet Buffer module will be installed in between the web cutter and the Smart-binder. The SBS-100 buffer receives printed sheets at a constant rate from the web cutter (defined by the printer speed of 127 metres a minute), stores these sheets and feeds them at variable rates into the Smart-binder depending on the number of sheets in each booklet. The SBS-100 enables very thin booklets (for example 8 pagers and even 4-page single sheets) to be mixed with thicker booklets while maintaining a constant, high printer web speed. It even allows the in-line Smart-binder to stop and restart if necessary without pausing the printing operation. The SBS-100 buffer module enables customers to benefit from in-line finishing, without reducing print efficiency.

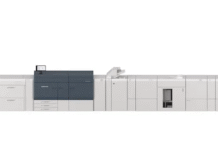

Ricoh to showcase Pro VC60000

Ricoh will be showcasing in action the very recently announced Pro VC60000 at Hunkeler Innovationdays 2015. Described as the future of graphic arts production and a game changer that will set a new benchmark for quality in its class, the Pro VC60000 has created some buzz amongst analysts and professional production print businesses. At Ricoh’s stand, opposite Hunkeler’s, visitors will also be able to see the brand new color cut sheet presses, as well as the latest addition to Ricoh’s TotalFlow solutions range – BatchBuilder.

Screen

Screenwill again exhibititslatest highspeedTruePressinkjettechnologies at the Hunkeler Innovation Days event 2015.TheTruePressJet 520 isin factthe mostsuccessfully sold and installed inkjet presswith combined sales by its OEM partnerRicoh and by Screen itself.

Just after the last Hunkeler event in 2013, Xerox announced its acquisition of Impika – a small but innovative engineering company that always attracted enormous attention at Innovationdays. While this gives Impika’s high speed inkjet presses global marketing clout, for Xerox it filled an important space in high speed webfed printing where the company was late and that its own developed ‘crayon press’ still needed time. We look forward to seeing either the 511 mm wide Impika Evolution 4- color press which runs at 254 metres a minute with capability to handle paper from 60 to 160 gsm width, or the Impika Compact or Reference presses that run at half the speed. It is not yet clear what Xerox is likely to show but we are guessing that an Impika press will be at its stand.

With each successive innovationdays, the event has enhanced its international reputation. Despite this growth, the Hunkeler Innovationdays has retained its compact scope, so the event provides a deep and complete industry overview. The event is focused on integrated total solutions and practical applications, so visitors become acquainted with the latest developments in all areas of production and finishing processes for digitally manufactured printed products.