The Danish Technological Institute and Heatflow ApS have demonstrated a 3D-printed cooling solution for data centers that promises to reduce the huge energy consumption required to keep the servers and GPUs cool. This energy footprint represents the hidden environmental cost of cloud computing, which has increased exponentially with the rapid adoption of artificial intelligence.

Simon Brudler, 3D-printing specialist and senior consultant at Danish Technological Institute, commented, “Besides the actual IT hardware, the corresponding cooling infrastructure is one of the major energy consumers in a data centre – and therefore the greatest potential to improve overall system efficiency.”

This new solution uses passive two-phase cooling, which, unlike conventional air cooling, relies on a coolant that evaporates at the hot surface. The vapour naturally rises due to differences in density, condenses elsewhere (where it releases heat), and returns as liquid through gravity. This passive two-phase process with coolant – a so-called thermosiphon principle – requires no pumps and thus consumes no energy for heat removal.

At the same time, evaporation is much more efficient than traditional cooling with air and liquid, so the amount of heat removed from the computer chip is much higher – and the chip remains cooler, helping to extend its lifespan.

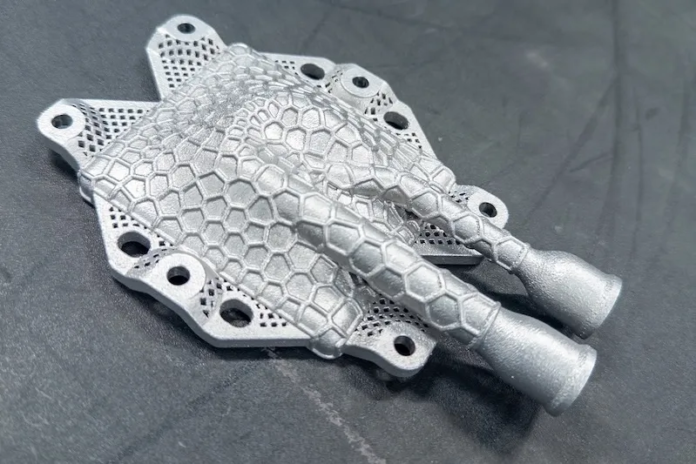

The key component in the system is the vapour chamber or evaporator, which is located between the hot spot (such as electronics or a battery) and the integrated liquid/gas section. Heatflow and the Danish Technological Institute have developed and manufactured the evaporator component using 3D printing as part of the European AM2pC research project. AM2pC aims to develop structures and designs as well as process parameters for the additive manufacturing of such parts. In this case, the evaporator achieved a cooling capacity of 600 watts in tests.

Brudler explains, “By 3D printing the component in aluminium, we can integrate all necessary functions into a single part. This eliminates assembly points, reduces the risk of leaks, and makes the component more reliable. At the same time, we use only one material, which makes it easier to recycle.”

Paw Mortensen, CEO of Heatflow, who led the project, stated, “We are seeing a development where the power density in servers is increasing faster than ever before, and traditional air cooling is simply no longer sufficient. With our two-phase solution, we can remove heat passively without pumps or fans, which significantly reduces the energy consumption for cooling.”

In addition, the solution removes heat at temperatures between 60º and 80ºC, which is much higher than traditional air cooling and means that it should also be possible to reuse that heat in the local heating network without additional energy input. Equally, this heat could also be used for other industrial processes such as manufacturing textiles, paper and pulp, or for heating greenhouses – if they are located close to the heat source.

Brudler adds: “In the project, we did not focus on the integration with district heating itself, but we have demonstrated that the technology enables it. This is an important step toward more energy-efficient data centres that can contribute positively to the overall energy balance.”

This solution was developed as part of a European research project called AM2pC that ran from 2023 to 2025 with a budget of DKK 10 million. It also involved Open Engineering from Belgium and Fraunhofer IWU from Germany. You can find further from Heatflow and more information on the Danish Technological Institute at dti.dk.