The consulting firm Bain & Company was engaged by Fedrigoni, a leading Italian fine paper manufacturer, to optimize the company’s entire value chain, in particular with the help of digitalization. Voith was impressed with its digital product portfolio and commissioned to supply the digital process control system OnEfficiency.Strength to enable more efficient paper production.

“This is a groundbreaking project that revolutionizes the dogmas of paper machine control and management,” emphasizes Libero Grandoni, production manager at the Fabriano mill. “We are excited about the digital solution every day, and I’m happy to be able to produce more with optimized settings while using fewer resources.” Fedrigoni plans to use OnEfficiency.Strength for other paper machines.

Fast implementation of Voith OnEfficiency.Strength

Voith started at the pilot site Fabriano in Italy, supported by Bain & Company, with the orderly collection of data, the basis for any digital solution. Firstly, Voith Paper analyzed all process, laboratory, and quality data from the last 12 months to show the correlations of the most important process and paper parameters and illustrate the process variations. In addition, the experts installed OnCumulus, Voith’s IIoT platform, to enable faster data access.

Subsequently, the Fedrigoni and Voith integrated project team decided to focus on the quality parameter of paper thickness as a first step. With the help of virtual sensors, ash content and virgin fiber use are now automatically optimized in terms of cost and quality, as OnEfficiency.Strength reduces fluctuations in paper thickness as well as virgin fiber consumption.

Although the installation was not on a Voith machine, the team could implement the digital control concept smoothly. “The integration into the existing system was extremely simple,” reports Grandoni delightedly. “Due to the very successful cooperation, data transfers and synchronizations from different systems that fit in time could be implemented quickly. Helpful training sessions demonstrated optimized use. Thus, OnEfficiency.Strength was ready for operation in a few days after installation.”

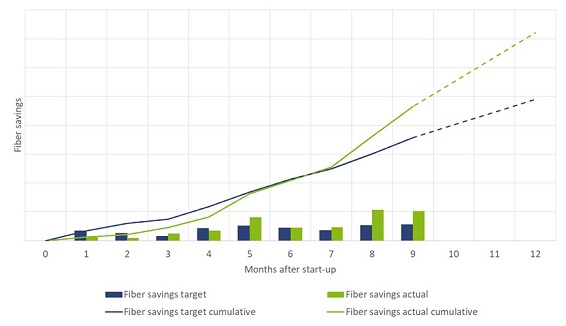

ROI under 12 months using new artificial intelligence technologies

Bain & Company accompanied the introduction of the digital process control and is impressed with the results achieved so far. “Voith made the cost-effectiveness and feasibility of the digital solutions a priority, and that was in line with Fedrigoni’s needs. In addition, we believe Voith, with its extensive technological knowledge, is at the cutting edge when it comes to digitization in paper manufacturing,” says Andrea Isabella, partner, and director at Bain & Company, explaining the decision.

“Digital transformation is a key enabler to support the improvement of all the performance areas of our operations: customer service, efficiency, and flexibility. The OnEfficiency project developed in Fabriano with Voith represents a basic milestone in our digital transformation. With a payback time of less than one year, the economic benefits are significant,” adds Mario Naldini, chief operating officer BU Paper & Security, Fedrigoni.