The InterTech Technology Awards honor the development of innovative technologies for graphic communications and related industries. Since 1978, the InterTech Technology Awards have honored the development of technologies predicted to significantly impact graphic communications and associated sectors. We list them alphabetically and have taken the liberty to occasionally add our comments.

The eleven recipients of this year’s InterTech Technology Awards comprise one web-to-print cloud software solution, a digital inkjet textile printer, and the trapping tool component of packaging prepress software. The 11 technologies selected to receive a 2020 InterTech Technology Award listed alphabetically with the winning tech named first.

“Our goal each year is to spotlight technologies which shape the future,” says James Workman, vice president, Center for Technology and Research, Printing United Alliance. “Each summer, the panel of judges and I scrutinize each submitted technology to evaluate its degree of innovation and potential for impacting our industry. It is a challenging process to select the recipients since all of the technologies are impressive.”

Customer’s Canvas – Aurigma

Customer’s Canvas reduces the complexity of developing online storefronts with design customization. The judges appreciated the customization capabilities enabling more print businesses to create their web-to-print solutions.

“We are proud to join the ranks of some of the biggest names in the printing industry. Our engineers and management team deserve every bit of recognition they received from the judges for their efforts,” says Dmitry Sevostyanov, CEO at Customer’s Canvas by Aurigma. “This award is a huge honor for our company and vindication that we are on the right path. This recognition imposes a responsibility on us to continue providing the highest level of service possible for our customers and helping companies utilize web-to-print technology to achieve their business objectives.”

EFI Reggiani Bolt

The single-pass Bolt digital 72-inch wide inkjet textile press can print at 295 feet a minute. Its quality and speed increasingly make digital textile printing more and possibly alleviate the environmental impact of conventional textile printing.

Esko Trapper

This is an automated trapping solution for packaging based on comparing adjacent colors and objects and their edges. To improve apparent register while printing and a software improvement on Esko’s own formidable trapping engine and tools.

GMG ColorCard

A cloud-based reference software system using spectral colors should be especially useful for digital inkjet and even for flexible packaging where the inks need to be formulated based on the substrate, and where the use of densities for measuring colors and inks is not adequate. The GMG ColorCard can simulate the target color or ink and the resulting appearance of the intended print process and substrate. A huge step forward if brand owners are ready to give up the obsolete practice of matching shade cards visually for packaging work.

HP Indigo 100K Digital Press

The first Series 5 HP Indigo press, the Indigo 100K digital press prints up to 6,000 B2 (750 x 530mm) sheets an hour. The improvement in speed, productivity, inline color quality controls, and the paper movement, including the new feeder with grippers and stacking in the delivery, make it viably competitive to multicolor offset presses.

HP PageWide Web Press T240 HD with inline H&B ExcelCoat Web Coater

Partnering with Harris and Bruno on HP’s 22-inch-wide inkjet web press, the coater can apply aqueous or UV-cured coating on either or both sides of the web at full printing speeds. Coatings can be changed quickly leveraging the press for commercial and direct mail applications.

Kodak Prosper QD packaging inks and film optimizer agent

Water-based pigment inks on flexible films at high speeds advance the digital printing of flexible packaging. Kodak’s novel chemistry means that instead of having a different ink set for each substrate type, Kodak’s primer (also called the optimizer agent) normalizes diverse substrates and for digital printing with similar quality. The ink and primer system is approved for indirect food contact, and the printed film can be further coated and laminated with high bond strength.

Komori GLX40RP double-sided press

The GLX40RP multicolor offset perfecting press prints both sides of the sheet in a single pass without turning it over. Capable of handling heavier substrates than a normal perfector, this design saves paper since one only gripper margin pulls the paper through to print both sides, unlike most perfectors. The system also allows new configurations with a coating of one side before the other is printed. However, this is not an entirely novel innovation since perfectors without turning the sheet over have been seen before in Japan from other manufacturers.

Uteco and Kodak Sapphire Evo M Press

Using Kodak Stream continuous inkjet (CIJ) technology, the 24.5-inch wide Sapphire Evo M is the fastest digital solution for printing full process color on flexible packaging. It prints flexibles at 650 feet a minute and paper even faster. With a flexo white ink option and other inline options coming from Uteco’s domain knowledge in flexible packaging, we have been impressed with the output since it was first shown at Labelexpo Europe, and output samples were shown at K2019 in Dusseldorf. The wider W version has also already found buyers.

Using Kodak Stream continuous inkjet (CIJ) technology, the 24.5-inch wide Sapphire Evo M is the fastest digital solution for printing full process color on flexible packaging. It prints flexibles at 650 feet a minute and paper even faster. With a flexo white ink option and other inline options coming from Uteco’s domain knowledge in flexible packaging, we have been impressed with the output since it was first shown at Labelexpo Europe, and output samples were shown at K2019 in Dusseldorf. The wider W version has also already found buyers.

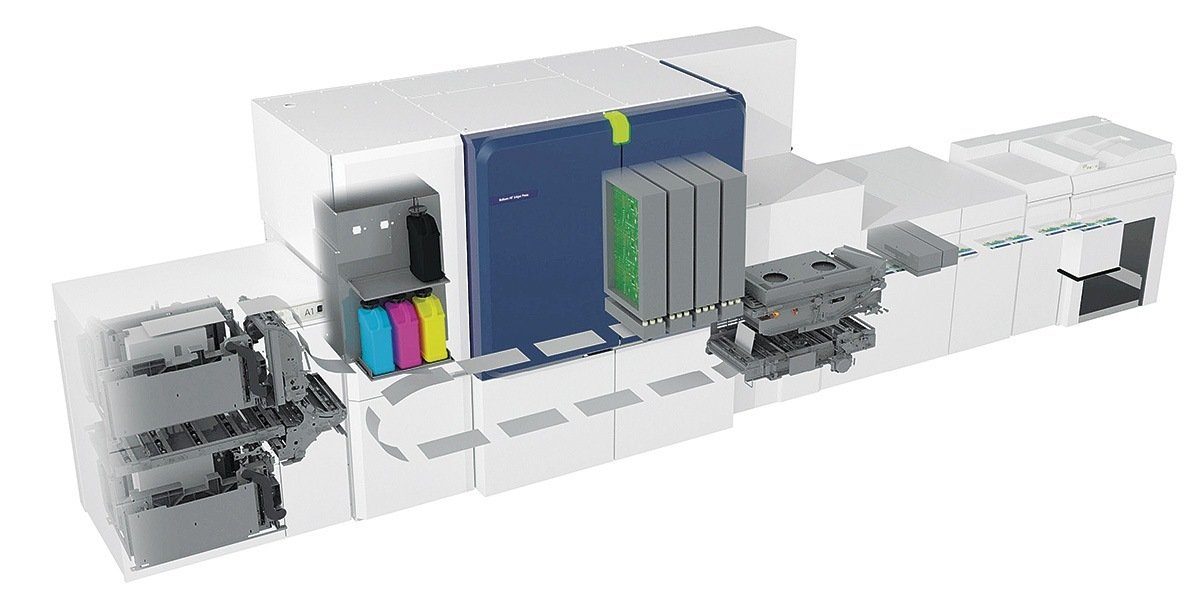

Xerox Baltoro HF inkjet press

The Xerox Baltoro makes production inkjet widely accessible with its 14.33 x 20-inch format (A3 plus), with a small footprint and low energy use. Meant to be more viable than other digital inkjet presses of this sheet size, the Baltoro is a perfector that can print both sides of the sheet automatically at speeds up to 300 pages a minute with image quality driven by ‘Automated Intelligence.’ The press requires no primer for pinning the color inks, and there is an automated closed-loop color quality control. The press structure, the paper movement, and the closed-loop color control are adapted from the Xerox iGen toner-based digital press.

The inline spectrophotometer is from X-Rite with M1 illumination to recognize the optical brighteners used in many papers. The color calibration for new substrates is easily performed using the Xerox FreeFlow Server interface, and Pantone shades can be specifically fine-tuned in case the front-end transforms, and rendering is not satisfactory. The FreeFlow print server also has the Cost Quality Optimization tools for ink calculation, a cloud-based service free to Xerox press users.

The HF stands for the High Fusion W-series inkjet heads that provide true 1200 x 1200 dpi resolution that enable the Balotoro to print on a range of offset coated media with finishes such as matte, silk, and satin. The press is rated up to 300 pages and a duty cycle of up to 3 million pages a month.

Xitron Navigator DFE

Xitron’s new digital front end gives inkjet press manufacturers a new browser-based quicker to the market alternative. Press operators use its browser-based interface for job preparation and color quality control for complex variable data print projects at full speed. The Navigator DFE should help in bringing down the overall cost of digital color production presses.

This article was first published in the October 2020 print issue of Indian Printer & Publisher.