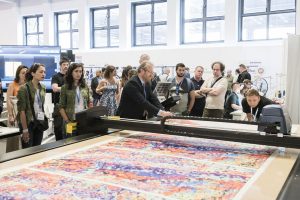

Print Make Wear – the new fast fashion factory experience created within the Fespa Global Print Expo 2018 – added a colorful and educational visitor feature to the event, addressing the rising interest in garment production and printing within Fespa’s global community.

467 individual delegates registered specifically for Print Make Wear. They were joined by the 17% of visitors to the wider FESPA event who came with a specific interest in garment decoration and manufacturing, and who visited the Print Make Wear area, as well as more than 2,000 visitors who took advantage of the expert-guided feature tours.

Technology investment was high on the agenda of visitors to Print Make Wear, with more than half planning to invest within six months, supported by average investment budgets of over EUR 180,000. The audience comprised 90% senior managers, with 76% of visitors having purchasing authority.

Many prominent sportswear, clothing and promotional apparel brands were represented among the delegates, with visitors typically occupying business, manufacturing, product development and technical roles. Their feedback shows that Print Make Wear at Fespa was viewed as an opportunity to update industry knowledge in the areas of increased efficiency and sustainability, workflow and technology and evaluate equipment and technology to inform future investment.

Print Make Wear is the latest addition to Fespa’s visitor offering around textile printing, which was a focus area for 34% of the 20,442 visitors to the expo. The Fespa 2018 Print Census, a worldwide survey of over 1,400 service providers published during the event, explores many aspects of textile and garment printing. The survey highlights sports apparel and fast fashion as two major growth applications, and emphasizes growing adoption of digital printing technology in response to requirements for faster time to market, small batch production, economical prototyping and customization.

56% of FESPA Print Census respondents active in textile printing have invested in digital printing technology, with 19% planning to do so in the next two years. Productivity is the major investment driver for 69% of textile respondents, while more than half are looking to print directly onto untreated materials.

Print Make Wear exhibitors shared their positive feedback on the inaugural event. “For us, Print Make Wear was very successful and it was a great opportunity for us to showcase what is possible using our transfer printing equipment,” says John Selfhout, manager – Marketing & Sales at Klieverik. “Education is key within this market area to help printers realize what is possible and Fespa’s approach with Print Make Wear helped with our brand recognition with a diverse audience of print providers and garment producers.”

“2018 was the first time we exhibited at FESPA because of the Print Make Wear feature. We found it an extremely valuable brand building exercise where we gained good visibility with a new audience for us,” notes Eoghan Murray, marketing manager at Juki Central Europe. “Our stand in Print Make Wear received good footfall and generated good leads. We got a lot of facetime with designers, whom we may not have seen at any other exhibitions.”

Head of Events at FESPA Duncan MacOwan comments, “Our research shows that, while the garment sector has been slower than other speciality print segments to transition to digital production, this is changing, driven by brand owner demand for streamlined production in the interests of reduced waste along the supply chain and increased flexibility to seasonal and local demand.” Based on the positive response to the first edition, Print Make Wear will be a feature at regional FESPA events and the FESPA Global Print Expo 2019, which takes place from 14 to 17 May 2019 at Messe Munich, Germany.