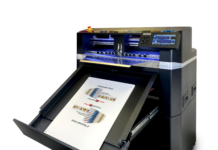

Shree Balaji Printing & Packaging in Baddi, Himachal Pradesh, recently started a prepress trade bureau for supplying litho plates to offset printers. The company has installed a Potevio-Eastcom DX1160T CtP system with a Glunz and Jensen processor.

At an open house event, Shree Balaji, which uses Fujifilm plates for its own work, displayed the capability of its new bureau using dedicated packaging solutions that included plates as well as the chemistry from Fujifilm. “The bureau was started just a few days ago and we are already processing around 140 plates a day. We are going to increase this to around 400 plates a day in this month itself,” says Anil K Modi, partner at Shree Balaji.

According to Modi, the new bureau will make plates for around 50 local offset printers and will also extend its reach to neighbouring areas as well. “There was a need for a prepress bureau in Baddi to help printers deliver print products on time. And with our bureau in place, that need has been met to a large extent,” Modi says.

With the objective of making offset printing and packaging more profitable with Fujifilm’s dedicated packaging solutions, printers and converters at the open house were provided a first-hand view of the Eastcom CtP platesetter at work and were introduced to Fujifilm’s dedicated packaging solutions that included workflow, plates and chemistry. The open house was followed by a technical session at Hotel Gianz where Vikram Bindal, president of Baddi Print Association was the chief guest for the evening. The open house and the technical seminar were attended by around 50 printers.

SM Ramprasad of Fujifilm says, “Fujifilm’s plates are resource-saving, that leads directly to improved profits.” While talking about Fujifilm Superia, Ramprasad says, “Fujifilm Superia is a comprehensive and integrated solution capable of reducing resources at five different key areas – material, labour, energy, and environmental emissions.” The five resource-saving benefits are achieved through Fujifilm’s lineup of integrated and optimized Superia solutions which include a range of CtP systems, pressroom chemistry and software. He adds, “Be it for short-run or long run jobs – we follow a one quality, one price principle.”

Flenex FW and Superia-ZP plates

Fujifilm’s advanced, water-washable flexo plates are designed to provide better print quality for a wide range of flexo applications, while delivering allround production performance. Superia-ZP is the third generation of Fujifilm’s processless ZP plate, and the company’s most advanced printing plate ever, incorporating high performance coating and micrograining technologies. This plate eliminates the need for a processor and can be mounted on the press directly.

Started in 2007, Shree Balaji produces monocartons converting around 2.5 lakh sheets a month. The new prepress bureau is set up within the 500 square metre plant. For printing monocartons, the company has a complement of offset presses, diecutters, laminator and a foldergluer.