Global Graphics, one of the leading developers of software platforms for digital printing, has launched Version 11 of the Harlequin RIP, which transforms design and prepress data into a format that can be printed and feeds those pages to the press. The Harlequin RIP is compatible with a wide range of PDF design tools and compliant with industry standards.

The new version, Harlequin 11 offers improved inkjet output quality, more controls for variable data printing, and contains new features for labels and packaging applications. It also introduces a new feature whereby each graphic is rendered only once even if it is used in multiple positions on a page. Harlequin 11 is available in two editions – the Harlequin Host Renderer 11, which powers the digital front ends used in high-volume digital production environments; and, Harlequin MultiRIP 11 for conventional and light digital production printing.

Print service providers who upgrade to Harlequin MultiRIP 11 will benefit from many new productivity features such as speed enhancements targeted at image heavy jobs so that in light production printing, where presses are driven by a single RIP, pages are fed even more quickly to the press, increasing productivity so that print service providers can fit more jobs into a shift. Moreover, MultiRIP 11 offers quality enhancements such as image snapping.

Some special colorants should not knock out of, or be knocked out by, other colorants. A varnish should never knock out of other colors, for instance, a white ink laid in under other colors should not be knocked out by ‘real’ graphics in other inks. Harlequin 11 includes configurations that allow these overprints to be controlled

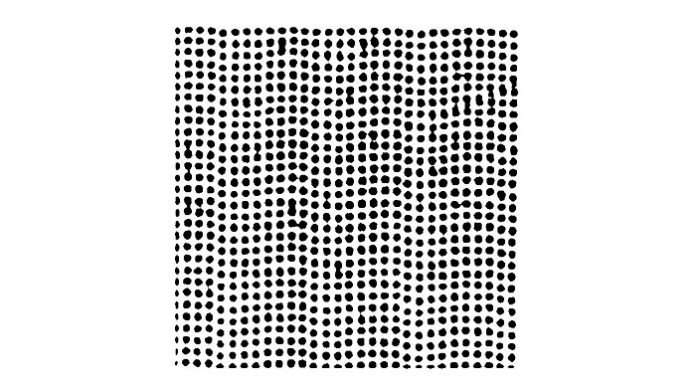

Digital screening

At drupa 2016 Global Graphics (Stand 70B21\C20) will introduce the Harlequin Multi-Level Digital Screening engine. This engine is part of a new service the company will introduce to inkjet developers at drupa, that sees technicians measure test prints from single-pass greyscale presses, and process the results through the new Digital Print Quality Optimizer tool. This tool calculates optimized patterning and overlaps for the various ink drop sizes available, to overcome common high-speed inkjet press problems such as streaking and mottling.