With 495,000 square metres of indoor capacity, Hannover Messe is the single largest exhibition facility in the world. Every year, it hosts the Hannover Fair, which has been split in two since the 1980s: the world’s largest IT fair CeBit and, three weeks later, the actual Hannover Fair, an industrial manufacturing fair covering everything from machine parts and materials to automation and innovation. During the fair, specialized exhibitions sometimes cover specific areas, such as sealers and fasteners and, this year for the first time, industrial printing.

Although InPrint 2014 showed a lot of overlap with Fespa, particularly in large format industrial printing, textile, ceramics, screen and its associated software applications, it offered a highly interesting opportunity for checking out the latest developments and trends in inkjet printing on irregular substrates and 3D objects and, most of all, 3D printing. What became fully clear at the show, is that printing in 3D is already far beyond the consumer and prototyping stage, and that mature 3D printing technologies are being applied in manufacturing processes. Jaguar Land Rover, for instance, is one of the largest users of the technology, for prototyping, testing and even for a bit of production.

Ironically, 3D printing technologies including the presses, materials, scanners and software could be spotted at several other areas of the Hannover Fair as well. Applications ranged from industrial design components, dentures, spare parts for aeronautics and Formula One race car developments, supply chain fixes, electronics and production parts to packaging converting applications such as moulds for resin injection and blow moulding, moulds for pulp moulding, and even one-way moulds for steel foundries. Developers of CAD-CAM software actually dominated the fair’s hall dedicated to software, offering industrial design applications that can be used as 3D printing prepress. The main exhibitors in this area included France-based Dassault Systems and Japanese iCAD.

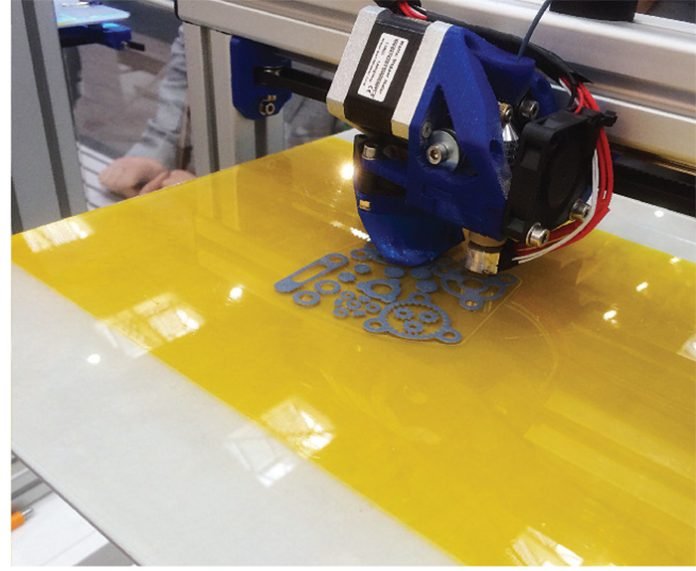

The basic idea of producing a 3D object by printing it in thin layers, layer-after-layer, by means of print heads typically developed from piezo inkjet technologies, has so far resulted in a variety of presses ranging from simple US$ 2,000 desktop devices fed by thermoplastic threads to heavy-duty machines printing thermoplastics, photopolymers or stone-grit binding materials at the US$ 50,000 to 300,000 end. Exhibitors in this area included Stratasys, 3Dsystems, the Fraunhofer research institute and some smaller companies such as Afinia and Voxeljet. Xaar staged demonstrations of its 1002 AMp print head for 3D printing or what it calls Advanced Manufacturing.

Printing on 3D objects

Apart from some of the main players in industrial inkjet, such as Agfa, Canon, Durst, Epson, Mimaki, Ricoh, spgprints and Xerox, there were several technologies on show for printing on 3D objects or irregular surfaces — mainly from Fujifilm- Dimatix, KBA-Kammann and Ecogenio. Screen printing technologies including printed electronics were the domain of Fespa- oldtimer Thieme. The relatively compact show — some 100 exhibitors

— was completed by many of the relevant ink suppliers and software developers also frequenting Fespa. InPrint 2014 has however been a very interesting show in its own right,

hopefully to be continued.