Okhla-based commercial book printer Rahul Print O Pack installed an 8-color Heidelberg SX102 in a customized 25 x 37-inch format in February 2024. The reduced format of the new SX 102 8-color sheetfed offset press matches the size and format of the company’s previous CS 92 and CX 92 4-color presses, meaning that all the formats and plates are standardized and work can be easily planned and printed on any of the available presses. Efficiencies in offset plate and blanket sizes, and other inputs are said to reduce the operational costs of running the press by as much as 20%.

The company has seen rapid growth over the past six years with the installation of its first two Heidelberg CS92 4-color presses in 2018 and 2020 and the addition of a CX 92 4-color press in April 2023. Running out of space in its main 16,000-square-foot plant where the planning and prepress and CtP platemaking are done for all the presses, the SX 102 8-color has been commissioned in a new 20,000-square-foot plant. As a commercial and book printer, the company has two Heidelberg SORD single-color presses running to full capacity and a single-color perfector as well.

In the prepress department, Rahul Print O Pack has Heidelberg Prinect software and can process around 47 – 48 plates per hour on its CtPs during the peak season from October to April. In addition to the older Heidelberg Suprasetter, a new Heidelberg Suprasetter A106 CtP system has been installed and will be moved to the new plant containing the SX102 8-color perfecting press.

Rahul Soni says that his father Ajay Soni, who started the business, insisted on maintaining standard plate sizes so that the commercial book printer need not book work according to the press sizes. “Without unnecessarily complicating operations, this is a very good format size, and if we wish to opt for packaging print in the future, the size works for 80% of FMCG and 100% of pharma packaging,” he says.

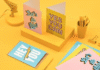

Rahul Print O Pack produces specialized combinations of children’s books and activity-based learning kits, including their unique add-ons, inserts and packaging. Soni says, “We have produced many early learning and pre-primary titles for nursery, LKG, and UKG, that involve special effects and packaging-oriented work including some manual fabrication and glitter effects. These orders involve substantial creativity – we work as an extended team with our clients and assist them with specifications and production of glitter sheets, gumming sheets, die-cut, tipped, and tracing paper inserts. We help produce the kits for this segment, which are an attraction to children, and deliver a complete package. These products are massive hits – and for the past 5 to 6 years, we have consistently kept receiving orders for them.”

Approximately, 25-30% of the commercial printer’s revenue comes from these book printing and book combinations and packaged kit projects for pre-primary titles, according to Soni. He says that usually, book printers don’t offer this type of a one-stop solution to publishers wherein you have flashcards, die-cut insets, activity books, and sticker books. Most publishers of pre-primary activity kits have a variety of vendors for the inserts. The content in the pre-primary books segment has become very diverse over the years – with additions such as value and activity-based education and an introduction to computers. Each book combo or kit can contain anywhere from 4 to 12 books.

When special drip-off, hybrid, raised, abrasive printed and coating effects are needed, Rahul Print O Pack outsources this step to nearby suppliers. Soni expects printing work in the specialized children’s segment to grow by 50% in the next academic year, adding that though this kind of print work is very tricky and complex, requiring intricate details, it is likely to grow into a substantial business in the near future. “This kind of work results in capacity utilization, which, in turn, improves productivity,” he says.

The printer currently has a daily production capacity of 50,000 to 55,000 paperback books and is looking to expand it to 60,000 in the current financial year with additions in the binding department such as saddle stitchers and perfect binders. The folding machines are each replaced turn by turn after 6 or 7 years of use. In its binding and finishing operations, it acquired three Aster 180 sewing machines in FY 23-24 while another awaited machine is on the way. Though the commercial printer earlier had six manual sewing machines, it wanted to invest in speed and automation to bring its binding operations at par with its printing capacity. Apart from this, the commercial printer has added another perfect binder from Bindwel (formerly Welbound).

In the book printing segment, you need to have multiple profit centers, says Rahul Soni, adding they have recently added new names in their kitty of customers. “Being a Heidelberg customer, we generally have an advantage and we wanted to acquire the 8-color perfector for over a year to target larger print runs with shorter turnaround times. For an average print run of 5,000 to 25,000 copies, the 8-color Heidelberg SX102 is the best bet and we opted for this machine foreseeing the kind of business our new customers wanted to do with us in the near future. The output of the new SX102 is equivalent to two and a half 4-color CS 92 presses.”

“India per se is in a very good space to capitalize on the global trend of vendor and supply chain diversification, which is prevalent across industries. The book printing trade in North India is very seasoned and multi-generational and it is all the more important to continuously keep on increasing your market share,” he said.

The founder of the business, Ajay Soni, says that the company’s USP is that they always try to be flexible with the customer according to their requirements. With its array of Heidelberg presses, the printer is now easily handling print runs of 30,000 to 50,000 in-house. He adds that son Rahul thoroughly studies and compares the technology and presses on offer and is the person behind the company’s rapid growth and expansion over the past six years. “It is all due to his intelligence, he has always suggested the right machines at the right time.”

While Rahul Print O Pack is currently focusing on consolidation of its operations, it is also acquiring around two acres of land in Delhi’s outskirts for its expanding domestic printing operations. The company is trying to enter book printing exports and plans to acquire a complete Polar cutting system, including a jogger, pile turner and pile maker once it moves to a new purpose-built plant.

“This investment would be truly a game changer for us as it can cut the paper for feeding five presses in twelve hours. In addition, Indian paper has a lot of dust, which is a major pain area for us. It not only affects the quality parameters but also the final productivity. It is also not good for the machines and this could be solved to a large extent with the help of the jogger,” explains Ajay Soni. Trained manpower is also a very big problem in the commercial printing industry, he says, adding that it is extremely difficult to source trained resources and non-technical people are usually very tough to train in printing operations.

Rahul Soni feels the company is in a very unique position in the book space, adding that his father Ajay Soni built up the business for over 30 years with many loyal customers. “My father’s reputation for high quality and timely service in commercial print over three decades has paid off.” He also clarifies that he doesn’t anticipate the company diversifying into full-fledged packaging operations in the medium term. “We want to be among the best commercial book printers in India by 2030,” he says.