While the Indian print media industry is still trying to recover its earlier levels of prosperity, it has overcome the supply chain challenges of the pandemic largely thanks to the local manufacture of offset plates by TechNova, its partner for over 50 years. At the same time, the newspaper companies have been able to cut chemical effluents, reduce water usage and save on power costs due to the adoption, mainly, of Technova’s VioGreen Plus chemistry-free violet CtP plates right from 2014.

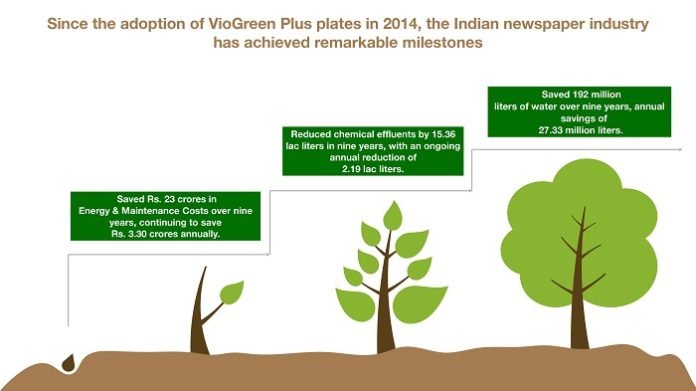

India’s first chemistry-free hi-resolution violet photopolymer digital plate for high-quality newspaper printing, the VioGreen Plus plates eliminate the use of water and developer with the benefit of high speed, long run length, and ease of use. The plate manufacturer says that since 2014, the industry has consumed more than 38 million square meters of VioGreen Plus plates saving 192 million liters of water so far with a current water-saving rate of 27.33 annually. Chemical effluents have thus far been reduced by 15.36 lakh liters in the past nine years while the industry is currently reducing effluents by 2.19 lakh liters each year. Energy and maintenance costs since 2014 are enumerated at Rs 23 crore with current annual savings of Rs 3.3 crore.

Indian newspapers praise TechNova’s green initiatives

Leading newspapers testify to both the environmental and cost advantages of having a local manufacturer of violet chemistry-free plates. Snehasis Roy of Bennet-Coleman, publishers of The Times of India and other dailies says, “We use TechNova’s VioGreen plates in all of our major printing centers that are ecologically friendly, use less water, and require less maintenance. Consequently, we address sustainability while simultaneously saving money. This, I believe, is the way ahead for the newspaper industry.”

Dainik Bhaskar’s Dinesh Sharma adds, “We were among the first newspapers to start using TechNova’s VioGreen Plus plates. Now these plates are used at 90% of our 51 print locations. These plates have helped us save water and energy and cut chemical discharge. The need of the hour is to focus on green and environmentally friendly printing technologies like the VioGreen plates.”

Many newspaper publishers are ready to attest to their positive experience in using the Viogreen plates over the past years. These include Mathrubhumi, ABP, Rajasthan Patrika, Prabhat Khabar, Lokmat, Dainik Jagran, and HT Media. Bhasi PT of Mathrubhumi says, “TechNova has been a wonderful partner for the newspaper industry over so many years. They have initiated so many projects to address the issue of environmental pollution and VioGreen Plus plates are one of them. These plates help newspapers cut chemical discharge and save costs. TechNova should be lauded for this effort.”

Others add that beyond cost, savings, the safety of employees, and environmental well-being should be key considerations for newspapers. Prabhat Khabar‘s RK Dutta volunteers, “TechNova’s VioGreen plates have helped us save power and water. Also, their SHE sessions helped our employees to take a proactive approach which not only safeguards them but also enhances operational efficiency by minimizing risks and potential disruptions.”

The TechNova EDGE experience

TechNova has stepped up to the safety, health, and environment challenges by engaging with the newspaper production personnel with its EDGE initiative that stands for excellence in all business processes; digital solutions that propel automation, precision, and seamless workflows; green solutions fostering sustainable goals; and, its entire ecosystem of consumables, equipment, software, and services.

The company’s array of innovations and enhancements across hardware, software, and consumables emphasize sustainability.

Its next-generation chemistry-free violet CtP plates work with a variety of available newsprint while remaining compatible with both conventional and UV inks. In addition, it is introducing its Kratos thermal process-less CtP plate, a clean, lean, and green solution streamlining the printing process and minimizing environmental impact.

TechNova says its commitment to environmental stewardship is underscored by eco-technology-based effluent treatment plants (ETP) and solvent treatment plants (STP) at its manufacturing sites. Moreover, the company says it will shortly introduce contemporary tools to help its customers measure and reduce their overall carbon footprints.

CtP life extension kits and automated workflows

TechNova extends the life cycle of violet plate-setters through specially designed life extension kits, resulting in optimal performance and longevity. Moreover, TechNova offers a range of violet engines from ECO3 and Krause, serving as replacements for End-of-Life (EOL) devices.

Automation workflows introduced by TechNova enhance efficiency, while software solutions improve print quality. An example is spiral screening, boosting print sharpness, while soft proofing software simulates press and substrate properties on-screen, improving quality throughout the printing process.

TechNova’s EDGE encompasses value-added services, including its digitized supply chain where customers can track ordered materials in real-time. Vendor Managed Inventory (VMI) ensures plates are available just-in-time, significantly reducing inventory carrying costs. The company’s commitment to the Indian newspaper industry is visible through its advisory services, offering audits, training, and consultancy in safety, health, environment, and energy conservation.