The Zünd exhibit at booth C20 in hall 1.2 illustrates how smart production automation offers great savings potential even for smaller graphics manufacturers by eliminating the potential for errors. Attendees will be introduced to PrimeCenter, the control center for generating print and cut files. In live demos, Zünd will be showing how the pick&place interface option controls robotic devices and fully automates the removal of cut parts and their placement at pre-defined locations.

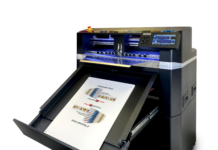

An automated, digital print&cut workflow is essential for standardized manufacturing processes and economical production. At Fespa 2022 in Berlin, Zünd exhibits solutions that help effectively automate graphics production.

There are many ways to optimize production and make it more efficient and profitable. Zünd offers automation solutions for many different scenarios. They are designed to automate and standardize the preparation of print and cut files. They support PSPs by providing tools for production monitoring and analysis and facilitating the removal and logistics of cut parts.

To create additional efficiencies in parts removal, job tracking, and even logistics, Zünd is also showing the visualizing option, another component of the Zünd cut center user interface and workflow software. Besides assisting the user during parts removal through projection, this option offers capabilities for labeling cut parts. Printed and affixed QR-codes help streamline and facilitate logistics.

For anyone looking to determine what aspects of their production workflow may have potential for optimization, Zünd offers the web-based monitoring and analytics software Zünd connect. Zünd connect uncovers productivity losses and provides key performance indicators that help users further optimize their digital cutting operations. It captures performance and availability KPIs from cutters integrated into the Zünd production workflow and uses this data to calculate Overall Equipment Efficiency (OEE).