Kornit has developed a new footwear solution for printing patterns to the upper part of a shoe that sits on the sole, which mainly consists of a new ink formulation.

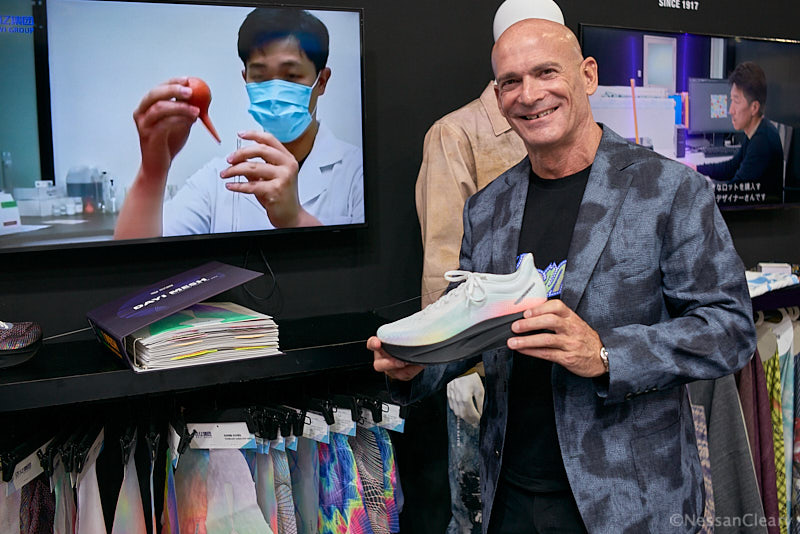

Kornit’s CEO Ronen Samuel says it was a combination of customers looking for new technology and Kornit looking for ways to use its XDI textured printing. “They liked what we were showing and printing on a wide range of fabrics,” he explained, “So once we had started building textures and layers with the XDI then this was the initial step.”

He continues, “So then we had to develop this so that it was robust enough and sustainable enough for footwear. We added some special polymers to the ink to make it really robust.”

Andrea Negretti, Kornit’s category general manager for the APAC region, explained that footwear is particularly demanding with the inks having to pass tests for durability and flexibility that far surpass anything that would apply to the common textile applications. He noted that it’s difficult to pass such tests with a digital ink, adding, “With screen printing you can add additives to make it stronger but digital ink is complicated.”

For now, the ink formulation only works with polyester, nylon, leather and faux leather. Kornit has been testing this solution over the last year with three customers— two in China printing to polyester and nylon mainly for the athleisure market; and one in Germany printing to leather and faux leather, mainly for fashion and higher value leisure wear.

The uppers can be printed in volume on the Presto. It’s also possible to print them on the Atlas Max and PolyPrint DtG machines though Negretti suggested this would be more suited to producing samples. In any case, you will have to flush the inks from existing machines for the new inkset.

Negretti says that although the main manufacturers are producing up to 1 million shoes per pattern, there is a growing demand for short run lengths with different patterns, adding, “To do this traditionally there are a lot of steps and it takes a lot of time.”

Kornit chose to launch this at the ITMA Asia show in Singapore, close to the main manufacturing centres because the key to this technology is the volume. Plenty of other vendors have printed shoe uppers before, but these are typically for very short run applications, often to tie in with marketing campaigns where the shoes are not expected to be used for long so there is less requirement for robustness.

What Kornit is offering is the opportunity for brands to order large numbers at short notice via its Kornit X network and online ordering system backed up by higher volume printers. Naturally this has brought with it the need to match the requirements of traditionally-manufactured shoes, leading to the need for the improved inkset.

Samuel says that this is a big opportunity for Kornit with the XDI ink, with Negretti adding, “I believe that this will get a good number of orders.”