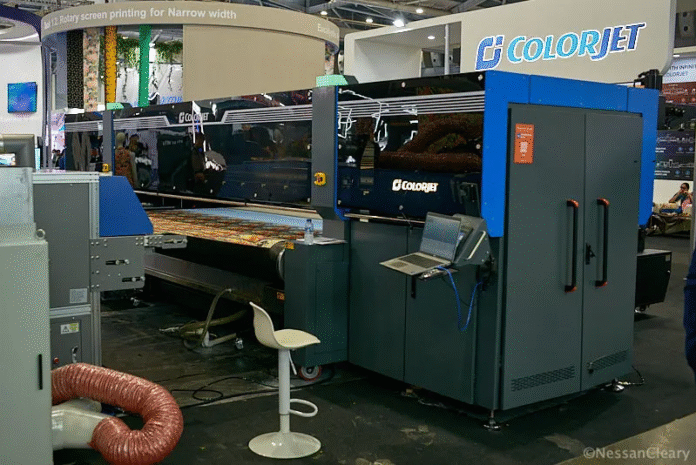

The Indian manufacturer ColorJet used the ITMA Asia show in Singapore to launch its latest inkjet textile printer, the FabJet Pro, a 3.2m machine mainly targeting home furnishings.

It’s primarily aimed at printing curtains, bedsheets, sofa covers and carpets. It’s been designed as an all-in-one machine for marge producers. ColorJet does sell other 3.2 m multipass textile printers. However, Smarth Bansal, associate vice-president of product management, says the advantage of the Fabjet Pro is that it offers a choice of three inksets, with pigment and reactive inks mainly used for cotton, and disperse ink for printing to polyester and silk.

It has room for up to 12 colors, depending on the inkset, but the majority of people will probably choose a pigment ink with eight colors, consisting of CMYK plus blue, red, orange and green. The ink itself is supplied in 10-liter plastic bottles.

There’s also a choice of printheads between Kyocera, with 600 x 600 dpi and Konica Minolta KM1024i with 360 x 600 dpi, neither of which include their own recirculation systems. Bansal says that some textile print customers simply prefer Kyocera heads, adding, “But the audience who use Konica Minolta feel that it’s much more forgiving and the failure rate is lower.”

Michele Riva, sales director for ColorJet, pointed out that the Kyocera heads were more expensive but could deliver higher productivity with fewer passes. He offered a more nuanced approach based on ink selection saying that the Konica Minolta heads were a good fit for use with pigment ink with binder, adding, “For reactive ink, Kyocera is a better advantage in terms of runnability because the production speed is much higher. I feel that for a direct dispersed ink then Konica Minolta could be a better choice than Kyocera because a sublimation ink is a more aggressive ink. It’s more similar to pigment ink in a certain way so it’s better to use a stronger head.”

He adds that to use a Kyocera head with pigment ink, it would be better to use a version with recirculation, but of course that would push up the cost quite considerably.

The basic model uses 32 printheads, with Kyocera or Konica Minolta, but the printer can be configured with up to 48 of the KM1024i printheads, increasing the productivity without pushing the price up too much.

ColorJet is claiming up to 1440 dpi resolution from the Konica Minolta printheads but of course that depends on the number of passes from the head carriage, with more passes slowing down the productivity. Nonetheless, Bansal says that a typical production speed would be around 600 linear metres per hour in a two-pass mode. According to the published specifications, two-pass mode with 32 Kyocera heads should produce 654 square meters an hour at 508 x 1200 dpi, while it takes 48 Konica Minolta heads to produce 535 square meters an hour at 360 x 720 dpi, also in two passes.

However, from several conversations with various ColorJet staff at ITMA Asia, it appears that the configuration that will make most sense for most users will be the Konica Minolta heads with pigment ink as a slow but reliable production workhorse.

There are three FabJet Pro printers currently installed. The first went to the Vapi region in Gujarati, the second to Delhi-NCR – both of these in India – while the third one has gone to Turkey. These have all opted for pigment ink, mainly because they all produce for export where the markets demand less water use and better sustainability.

The FabJet Pro uses a ColorJet edition of the InEdit NeoStampa RIP software. The price for the printer is around US$ $400,000 though this will depend heavily on the choice of printheads.