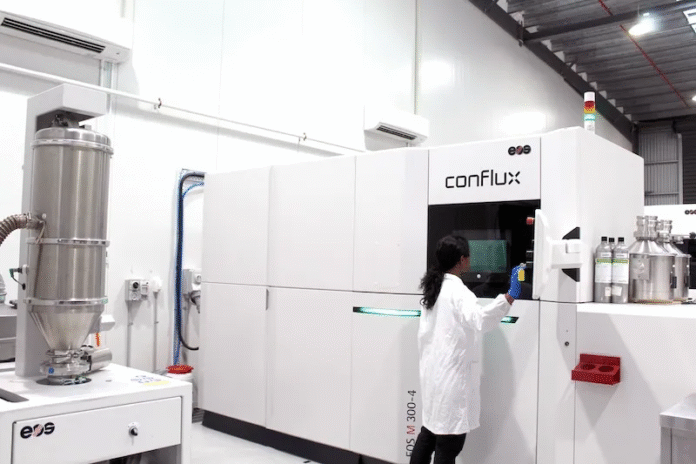

The Australian company Conflux Technology, which uses additive manufacturing to produce heat exchangers, is planning to open its first European business hub, with a new base in the UK.

These heat exchangers are primarily used in the aviation, automative and defence industries. They can also be found in a range of other machinery, energy systems and electronics – essentially anywhere that generates a lot of heat that has to be managed. Additive manufacturing is ideally suited to this because of its ability to produce complex internal geometries, such as thin walls and fins in order to dissipate heat. This allows a complete heat exchanger to be produced as a single part, which is smaller and lighter and with better performance than alternative methods.

Michael Fuller, CEO and founder of Conflux Technology, explained, “Europe is a key market for us – Conflux UK will not only shape the future of the automotive, motorsport and aerospace markets, but also establish supply chain resilience, so we’re excited and ready to expand our operations and work closer with some truly innovative companies.”

Fuller himself previously worked in European motorsport as a senior engineer for Formula One, World Rally and Le Mans race cars. From here he developed a patented heat exchanger that could be 3D-printed, setting up Conflux in 2015.

Conflux Technology already has a business development manager based in Germany and Europe already accounts for around 35% of the company’s business. It has a number of European clients, including partnerships with several Formula 1 teams, as well as companies such as Rocket Factory Ausberg, which offers low-cost satellite launch services, and AMCM (Additive Manufacturing Customised Machines), which is part of the 3D printer vendor EOS.

The new hub in the UK will initially focus on R&D, materials certification, and supporting customers with local supply chain constraints. The hope is that it will be expanded into a fully operational production centre as customer demand increases.

Last October the company raised $11 million in series B funding to expand its technology development and better support customers worldwide, including the new UK hub.

The funding also allows for further development of the Conflux Production Systems, or CPS, which is an end-to-end manufacturing solution for producing AM heat exchangers. It combines thermo-fluid design expertise and metal additive manufacturing to produce high-performance heat exchangers that are lighter and more compact.

Ultimately the company’s goal is to productize both its heat exchanger designs and the process of manufacturing them so that its customers can produce their own Conflux heat exchangers locally for quick and efficient production. This sort of distributed manufacturing approach is another hallmark of 3D printing.

You can find further information from confluxtechnology.com.