Although Hunkeler Innovation Days is primarily a show about post-press solutions, the digital presses are the main performers, driving both inline applications and providing reels for nearline finishing lines.

So it’s an important show for most press vendors, as Peter Wolff, head of marketing for Canon, told me, saying he regarded HID as one of the most important events in the global print calendar, adding, “For us this is very efficient. We don’t need to find out if people are just having a day out to see what these machines can do. Everybody we talk to has a reason to be here, to improve their business. And for the visitors it’s a good opportunity to have a very fair comparison.”

Many press vendors have used the HID event in the past to launch new products, but there were few surprises this year as most vendors had already announced their latest developments at the recent Drupa show. Nonetheless, there were a few interesting points and the show did highlight some of the current market trends.

The most obvious trend, as I mentioned in the first part of this story, is that there were a lot of sheetfed solutions for a show that in the past has been dominated by continuous feed printing. But looking at the presses themselves and the inline configurations that the vendors had opted to demonstrate, it’s clear that this is just part of the ongoing evolution of the inkjet press market. Improvements in print quality and productivity have inevitably opened up more opportunities in commercial printing, with most vendors opting to showcase short run book production and direct mail printing this year – where in the past, it would have been mainly transactional printing and mailing lines.

Heidelberg

This can be seen in Heidelberg’s decision to bring along its recently introduced Jetfire 50 B3 sheetfed inkjet system, based on Canon’s IX3200, which was running inline with a Hunkeler plowfolder and Starbook. Heidelberg has previously shown some limited postpress units at HID but this was the first time the company had brought along a press. This is an important step for Heidelberg because the Jetfire 50 will effectively replace much of Heidelberg’s B3 offset press sales. Drupa gave Heidelberg the chance to showcase this to the commercial print market, and HID allowed the company to demonstrate its capabilities to the short run book printing market. Heidelberg also took the opportunity to launch a new postpress module, the Fireline, for connecting nearline solutions (and which I will cover in the third part of this story).

To underline the significance, Heidelberg also brought along a member of its executive management board, Dr David Schmedding, chief technology and sales officer, making his first visit to the Innovation Days. He was in an upbeat mood, telling me, “It seems the investment mood of our customers is improving significantly so we are getting a lot of enquiries now.” He continued, “We want to be a key player in the industry and in digital printing. This time we have decided to present an end-to-end solution with a Jetfire system combined with near line for finishing with the Fireline because we want to show the industry that we are a serious partner for workflow software.”

Canon

Canon used its own sheetfed VarioPrint iX3200 to demonstrate a new integration with Horizon, which was shown for the first time at HID25. This saw the press running inline with a Horizon Ice StitchLiner MarkV to produce brochures in a single process without slowing down the press. The sheets come out of the press with the short edge first so the solution involves an RT50 Rotator to turn the sheets around, together with an interface with the press. Yoshihiro Oe, a director with Horizon, says, “We are open to work with anybody but the first one is Canon and we very much appreciate their cooperation.”

Otherwise, Canon’s stand was dominated by a ProStream 2133, a roll-fed press able to produce up to 133 meters per minute. This is designed for a variety of work including short-run brochures, direct mail, postcards, and calendars. It was shown as a roll-to-roll line with a new Hunkeler Web Extender WE8 to optimise the print quality along with a remoistening unit from Weko to prevent damage to the paper. Some of these reels were then finished through a Muller Martini line, which picked up the jobs through its Connex automated workflow.

Wolff said that Canon is still working through its order backlog from Drupa, adding, “And we have had sales here.” This includes one customer who came specifically to see the long sheet unit as it will help move more volume to inkjet. Canon also showed samples from the upcoming VarioPrint iX1700 and the B2 VarioPress iV7, which I’ve previously covered.

Kodak

Another theme is that inkjet press vendors are now increasingly talking about their continuous feed machines replacing offset presses for commercial work. To this end Kodak showed off its Prosper 7000 Turbo Press, which it claims is the fastest web-fed full-color inkjet press currently available with speeds of up to 410 mpm. Kodak’s CEO Jim Continenza claimed, “We built the world’s fastest printer and then we made it faster. This thing is a beast and it runs and it runs and we are very proud of it. It is made to last and it is made to make money.”

The first of these has just been installed at Mercury Print in the US, which is a long time Prosper user. The press was shown in Luzern in a roll-to-roll configuration with an unwinder and a rewinder designed and manufactured by Kodak, with Kodak’s aqueous Ektacolor inks. Kodak is hoping to use it to persuade customers to migrate larger direct mail, commercial, transactional, and book printing jobs from offset to digital. Elsewhere, Kodak demonstrated a saddle-stitched catalog being produced on a Horizon iCE StitchLiner Mark V, as well as a direct mail application on a Hunkeler paper processing line.

Kodak also showed a neat party trick, printing individual frames at 410mpm from a short film that had been shot on Kodak motion film stock at the standard 24 frames per second, and then videoing the frames in real time as the web entered the rewinder to play the film back on a large screen. There’s no commercial benefit from using the press as a giant flip book other than to highlight the breadth of Kodak’s technologies, from film to inkjet.

Continenza went on to give a more general overview of Kodak’s activities, which cover plates, film and now medical production. I’ll come back to Kodak in more depth in a few weeks when the company publishes its next set of financial results, which will allow for more context.

HP

HP showed off its Advantage 2200 continuous feed inkjet press, which made its European debut at the last HID show two years ago. This press is capable of 244mpm but the speed is affected by ink coverage and substrate choice. Consequently HP offers customers a choice of up to three drying zones to enable them to maintain productivity even with the most demanding jobs and stocks. This year HP demonstrated a new drying option that consists of the entry level single zone drying plus a new passive web cooling module, giving customers more flexibility at a lower price point.

Yale Goldis, director of strategy and commercial products at HP Industrial Print, says that customers would choose a single drying zone for uncoated media or two zones for coated stocks, adding, “We found there were people in the middle, who had a little bit of work that needed coated so it gives them an option to do that work.”

HP has now installed over 40 of the 2200 Advantage presses since they were first launched two years ago. Marc Johnson, senior global market development manager for HP Industrial Print, says that HP has added a number of new enhancements to the 2200 over the last two years such as a MICR option and on-press color profiling that makes it easier to create on-press color profiles in less than five minutes.

He added, “These things have all been offered to customers at no extra charge so that they invest in the platform and reap the benefits as they come.”

HP has also added a Performance economy mode that’s said to increase productivity by around 60%, with Goldis saying, “We see people use economy performance more for all kinds of work including book work.”

The 2200 Advantage was shown running inline with a Hunkeler Starbook Plowfolder, which can handle speeds of up to 250mpm. The combination should be suitable for medium book runs, as well as short runs down to single books. The set up demonstrated at Lucerne can produce up to 1,000 books per hour or 750 if a larger format.

Interestingly, Barbara McManus, vice president and general manager of PageWide Industrial at HP, pointed out that 95% of the inkjet presses that HP has installed over the last 15 years are still running including the very first T300, which was installed at O’Neils in California, USA.

HP also took advantage of the new focus on cut sheet printing to bring along both its 120K and 18K Indigo presses, the first time that its Indigo division has been at HID. Adam Bernt, product manager for HP Indigo EMEA, says “the name of the game is productivity” before introducing a number of new features including PQ Maestro, which uses AI to detect errors. HP also announced new Indigo consumables that are said to reduce waste and CO2 emissions. This includes CMYK+ electronics, with higher pigment concentration and a new PIP+ Printing Imaging Plate, which has been reformulated across two layers. There’s also a Regenerated Imaging Oil in-press recycling system for the ink carrier. All together these should result in fewer stops to replace consumables, which HP claims will save customers up to six hours a month.

Another interesting theme from the show was the growing demand for inline solutions with the Postpress units directly connected to the printer line. The perceived wisdom has been to keep the press and finishing lines separate because if there’s any problem with one of the numerous post-press units then the extremely expensive digital press also has to stop, totally fouling up any expectations of profitability based on productivity. And yet several vendors told me that more customers were asking for inline finishing with their presses.

Screen

Martijn van den Broek, regional sales manager for Screen Benelux explains, “In the beginning the finishing was less reliable and also the paper needed conditioning. And the way we heated the paper made it less stable. And every time the finishing stopped then the printer stopped and that was very frustrating for customers. So a lot of people started inline and then went offline.”

He continued, “But now they are changing back because if the finishing crashes then the machine keeps printing but at just 3mpm because of the buffer which gives you time to restart the finishing. So this is a great improvement.” He adds, “For transactional it makes sense because you have the same paper and so you just set up the finishing once and it will run. But if you have a lot of variation then you have more set-up time for the finishing.”

He points out that the finishing is becoming more automated. He adds, “Also with inline you only need to change the roll on the whole line and not multiple rolls on different lines.”

Screen brought along two continuous feed presses, including the 560HDX which I’ve already covered following its debut at last year’s Drupa show. For this year, Screen has updated its older 520NX with a new inkset and some enhanced automation to create a new 520NX AD variant, which I’ve already covered. More than most vendors, Screen was one of the first to embrace inkjet and embodies the changing nature of the continuous feed print market, from primarily transactional to now include high end direct mail, books and, increasingly, commercial print.

Fujifilm

Fujifilm showed off its Jet Press 1160CFG continuous feed inkjet press running on its stand, together with a Hunkeler line to produce promotional postcards. The press features a new paper stabiliser unit, of which Mark Stephenson, business development manager for Fujifilm Europe explained, “It will stabilise the paper for better printing for offset paper.”

Essentially this takes some of the moisture out of the paper before it goes into the press. This is counter-intuitive since most presses heat the paper after printing, to get rid of the water content in the ink, and often have to remoisturise the paper keep it from drying out too much. However, Stephenson says that taking moisture out of the paper before printing allows the paper to absorb more water from the ink so that there’s less drying required and less variation in the temperature in the press, which might otherwise damage the paper.

The press uses a hybrid ink that will work directly with conventional offset papers without requiring any primer. This is coupled with infrared heating to dry the inks.

Besides the Jet Press, Fujifilm also worked with Meccano Tecnica to demonstrate short-run book production and with a Horizon Stitchliner to show instant switching capabilities between books of varying sizes and pagination.

Right at the back of the stand, was an area reserved for Fujifilm’s printbar systems, including both the 42K Printbar and the Mini 4300, which are designed to be integrated into conventional presses or finishing lines to add digital print capability.

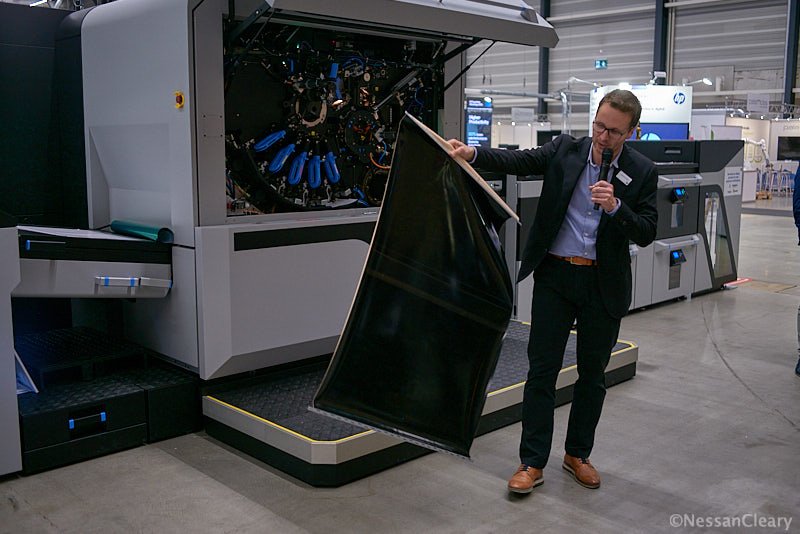

Ricoh

Ricoh’s stand was mostly based around its VC40000 press, which is itself based on a Screen 520NX. Ricoh also showed a single print engine from its Pro VC80000 press though this was not running. Instead Ricoh left the doors open to talk about its printing and drying system, which was already shown at Drupa, and which I have previously covered here. Ricoh had its electrophotographic C9500 cut sheet production press but mostly focussed on its workflow software. This includes TotalFlow BatchBuilder, for simplifying and automating various steps in short run digital production, and ProcessDirector, for managing production information and print processes.

For the final part of this report from this year’s Hunkeler Innovation Days I’ll go through some of the other post-press equipment that I came across. In the meantime, you can find the first part detailing Hunkeler’s new offerings here.

First published on 19 March 2025 in Printing and Manufacturing Journal. Reproduced here by permission.