Xaar has added two new printheads to its portfolio, the Xaar eX, and the Nitrox eX, but

unlike most printheads, these are targeted at a very specific market application – the

production of batteries, mainly for electric vehicles, or eVs, but also for other energy

storage uses.

To understand these new heads, it’s necessary to first take a look at this particular

application. Most batteries are made up of several cells combined to create a larger battery

pack. These individual battery cells have an insulating layer around the outside to reduce

the risk of electrical and thermal transfer. This insulating layer is typically a PET film, with

a pressure-sensitive adhesive layer on one side that is used to attach it to the battery.

However, there are some drawbacks to this approach, such as the risk of trapping air

bubbles behind the plastic layer. These air bubbles can expand if the batteries become hot,

which reduces the insulation. It also makes it harder to pack more batteries into tighter

spaces, which is a growing problem as vehicle manufacturers try to move to bigger, more

powerful batteries.

Graham Tweedale, chief operating officer at Xaar, explains, “Whereas today you might

have battery cells packed together in a frame and held together with fasteners, they want to move towards more structural adhesives to glue battery cells together to make a battery

pack. The problem is that the adhesive used to glue the battery cells together has a higher

strength than the PET film does, so there is the risk that the film might delaminate and

come off, especially if there was some sort of mechanical shock, which is quite likely in a

car.”

This change in the way that the battery cells are packed together is because most eV

manufacturers are now moving towards higher voltages, typically around 800 volts, and

faster charging speeds. This also increases the temperatures around the battery cells.

Tweedale notes, “So any of the issues you have with the PET film are exacerbated by

having to deal with this assembly in a higher temperature environment.”

This has led battery makers to look for processes that would be easier for manufacturing

and that could cope better with these issues. One option is to replace the plastic film with a

liquid coating. Some manufacturers have used spray coating to apply this liquid though it’s

hard to control precisely where the fluid is sprayed. That’s an issue for batteries because you want to insulate all of the battery cells but the face with the terminals can’t be spray-

coated. So where spray coating has been used in the past, the top face with the terminals is left without an insulating layer, which then limits how the cells are combined to create the finished battery pack without the risk of short circuits.

Consequently, many manufacturers are looking at inkjet as a more efficient way of

applying liquid coatings. Usually, this means a single-pass inkjet to fit into the established

production lines, which produce a battery cell every couple of seconds. Tweedale notes,

“That requires a fairly high level of throughput to make sure that you have the right uptime

to support that.”

The downside of inkjet is that it’s a much more fussy technology than spray coating.

Regardless of the application, there is always a process to find the optimum formulation of

the fluid to ensure that it can be jetted through the printheads while still hitting all the

performance characteristics for the end application.

Tweedale says that Xaar has been working on this project for some years now, noting, “We

have worked with everyone in the application. You have got to work with the fluid

company as it’s the fluid in the head that’s the key bit. We have worked with the battery

company because they have got to also accept that this will work and ultimately they are

the end customer. But our customer is the OEM who builds the machine, who would buy

the printheads to install. So we have had to work across all the different players in this area to get to the solution.”

The coating uses UV light to cure it from a jettable fluid to the final coating, which itself

can be relatively thick at over 100 microns. So the chemistry within this coating is quite

different from a standard UV ink. The fluid has to provide electrical isolation and thermal

protection without being compromised by the adhesive that’s used to glue the individual

battery cells together.

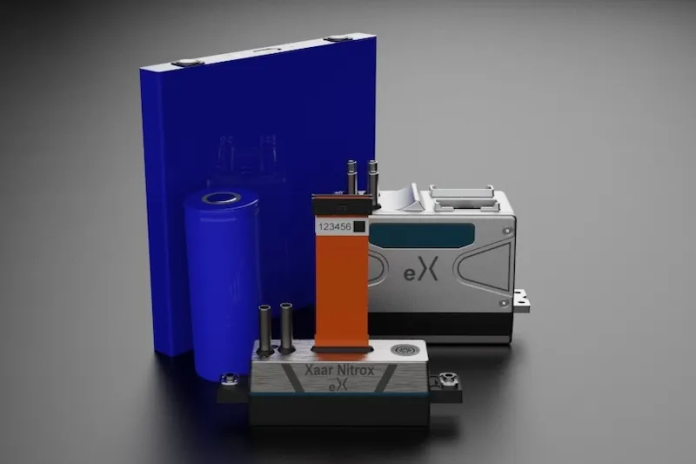

The battery cells themselves tend to come in two shapes, cylindrical or prismatic

(rectangular). Most eV battery cells today are cylindrical but demand is increasing for

prismatic batteries, mainly because the rectangular shape makes it easier for the

manufacturers to pack multiple cells together directly into the vehicle’s chassis, meaning more power in the same space. However, the rectangular shape creates a problem in being

able to apply the coating around the corners whilst maintaining a continuous and uniform

layer. Consequently, Xaar has developed two printheads, one each for cylindrical and

prismatic batteries.

The eX printheads

The main reason that Xaar has had to develop heads, especially for this application is

because the chemistry within the liquid coating could damage the structure of the

printhead, specifically the epoxies used to bond different elements within the head.

Tweedale explains, “Working with the fluid companies, we have added a special coating in

the printheads so that we can handle these UV fluids for the outside of the batteries, which

have got pretty specific properties. We have had to go through all sorts of validation and

testing for the battery companies to prove that they do the job and provide the function

that’s required.”

He adds, “And that’s why we have released these two new printheads because we have

done a lot of work to validate these fluids to jet them without any lifetime issue.”

So in reality these new heads are variants on existing printheads. Consequently, the Nitrox

eX is based on the Nitrox head. It’s a relatively compact head, with two rows of 1000

nozzles giving 360 nozzles per inch resolution. This has been designed for working with

cylindrical battery cells, where the cell spins around in front of the head so that an even

coating can be jetted in a single pass covering the entire cell.

The eX head, which is larger, is based on Xaar’s 2002 design and has four rows for a total

of 2000 nozzles with 720 npi resolution. This head has been designed for rectangular

battery cells. There are two channels but the process uses a single fluid type. Tweedale

says, “It’s really about laydown. On the cylindrical battery, because its spinning, you can

still get the right throughput with two rows. And on the prismatic batteries, we have got

four rows so that we can lay down enough fluid quickly enough.”

Both heads are available with a choice of 12pl or 40pl native drop sizes, with jetting

frequencies up to 36kHz and 24kHz respectively. This allows the Nitrox eX to jet up to

42g/sqm and the larger eX to drop up to 85g/sqm.

Both heads use Xaar’s ThroughFlow ink recirculation system, which keeps the fluid

moving right down to the nozzle plate and uses a very high flow rate that should reduce

blockages and air bubbles. This is supplemented by the SureFlow technology, which

pushes the fluid through at a higher rate to clear any blockages.

The other issue is that functional fluids tend to have quite high viscosity, much higher than

most of today’s printheads can handle. Xaar has made a virtue out of its ability to handle

high-viscosity fluids, which this project demonstrates quite neatly. These coatings are

typically around 50cP and above, with the Xaar heads able to handle fluids up to 100cP.

For reference, most printheads will usually quote around 5-10cP for graphic arts inks.

Xaar also has a partnership with Quantica, which has developed the NovoJet printhead

that’s able to handle fluids with up to 400cP viscosity. This could open up other

applications such as jetting adhesives.

Most OEMs apply some degree of heat to the printing system to improve the flow rate of

the ink. Tweedale says that UV fluids are typically jetted at around 45oC for this reason and

that Xaar hasn’t had to make any changes in terms of temperate control for this battery cell application.

He adds, “The underlying performance that we bring that makes this possible is the

ThroughFlow technology that we have and the high viscosity capability.” He continues:

“Being able to jet high viscosity has the advantage of keeping that very uniform coating all

the way around the corner of the battery.” The eX heads mainly operate in binary mode

though the greyscale capability can help manage the corners to ensure a consistent coating

all the way around the battery cell.

Tweedale says, “We have four different fluid providers who have got approval for the

fluids they have formulated by the battery companies. So these fluids have had to meet

whatever standards they currently have, which includes the lifetime of the battery and

crash resistance.”

Other applications

As well as eVs, the batteries can also be used for energy storage and Tweedale says that in

the future the process could be applied to consumer electronics. He adds, “We are working

with people to look at other places within the battery manufacturing process where inkjet could play a part. There are various processes used today, like applying a slurry when you

are making some of the active components within the battery and we look at whether or

not there are some areas that could be done via inkjet. If you can jet it we have a fairly

good chance of being able to do that because we can handle the high viscosities which

broadens the scope of things that you can inkjet.”

He concludes, “We believe it’s a reasonable-sized market for us. I think it’s a market where

we can bring real value. This move from an analog production process to a digital one, you

need our attributes to make it happen. And it’s an interesting area for us, batteries in

general, not just the coating but also active elements within the battery.”

It seems inevitable that in the future more printhead manufacturers will develop

specialized variants of their heads to cope with particular fluids for certain industries. We

have already seen inkjet expand from graphics to industrial printing and now we are seeing

the same technology being used directly in industrial manufacturing. This shouldn’t be a

surprise since inkjet is already widely used in additive manufacturing, AKA 3D printing.

This leads to the obvious question of how many other manufacturing industries will benefit

from moving from analog to digital processes.

The Xaar eX and Nitrox eX printheads are available and you can find further details on

them from xaar.com.

This article is republished by permission from The Printing and Graphics Journal www.nessancleary.co.uk