In a presentation on the second day of the show, Bruno Müller, CEO of the Müller Martini group, explained the strategy behind the group’s Hunkeler acquisition six months ago. Even though Hunkeler will be maintained as a brand and still has a separate booth at this year’s Drupa, its paper processing equipment can also be found at the Müller Martini booth, integrated into the group’s Connex workflow system. Currently, the sales and service networks of both companies are being integrated, with the perspective of converging and capitalizing on each other’s particular expertise and customer connections. Hunkeler’s systems have already been integrated into the Müller Martini group’s portfolio.

At Müller Martini’s 1,400 square meter booth, four production lines are running as part of Müller Martini’s contribution to ‘driving the digital transformation.’ According to Bruno Müller in his presentation, the company showcases the latest equipment, “to show how we can accompany our customers on their individual journey – into the increasingly digitalized future – and how they can consistently exploit the potential of new technologies with our solutions.”

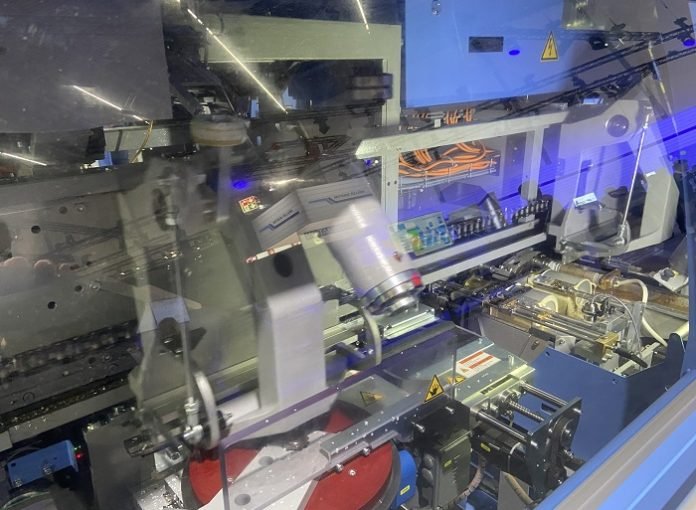

The equipment on show is entirely integrated with Müller Martini’s Connex workflow system and includes a new SigmaLine Compact, in combination with the Antaro Digital perfect binder and InfiniTrim trimming robot, enabling roll-fed digital printers to produce variable size products in a small space with fewer staff and a lower production waste rate. The highlight of the SigmaLine Compact, an addition to the SigmaLine III product family with web widths of up to 42 inches, is its flexibility in book block production. While most digital folders work with a blade, former folder, or plow fold unit, the SigmaLine Compact uses Müller Martini’s patented air knife technology to process signatures. The Antaro platform with six clamps can produce up to 2,000 books an hour.

Another production line includes the Ventura MC 200 book sewing machine combined with the VFN 700 fold hold.down press, which can produce extremely economical book blocks of the highest quality. After the Ventura MC200/VFN 700 combination, the Cobot Omega 693 by Solema processes five stacks per minute and stacks the finished book blocks with different stacking schemes up to a pallet height of 1500 mm. This combination assists and unburdens the operator on the book sewing machine and increases production efficiency.

The Primera Pro saddle stitcher, with speeds of up to 14,000 cycles per hour, is shown at the booth in a continuous, labor-saving production process of multiple small jobs.

Also at the Müller Martini booth, Hunkeler showcases its recently developed Starbook SF8 Sheetfolder at speeds of up to 1,000 units (stacks, blocks or books) an hour, in a combination with Müller Martini’s Vareo Pro perfect binder.

According to Bruno Müller, the digital transformation offers new opportunities for both machine manufacturers and customers. “Increasingly, it is not the individual machine that is decisive, but several machines in a network. This means that the higher-level workflow, which dynamically controls the production process, is becoming an important success factor.

The opportunities for customers, in turn, lie in new product forms such as personalized content or the use of high-quality materials – but also in on-demand production, thanks to which storage costs or overproduction can be eliminated.”

“The success of a new system depends on the entire process and not primarily on the chosen printing technology. Small batches are also possible in offset printing. Therefore, the economically viable production of short runs does not necessarily require digital printing presses, but above all an end-to-end process from prepress to dispatch.”

Bruno Müller therefore sees the Connex workflow system as the key driver behind the digital transformation. A typical example that was shown on the machines after Müller’s concise presentation was correct impositioning of pages with all the necessary marks and variable data needed for further processing.