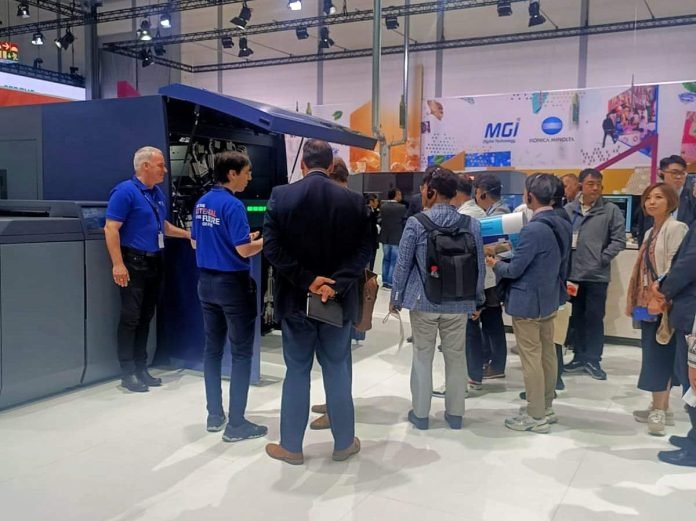

The Konica Minolta stand was busy as were most of the digital press stands at drupa. The 8-year gap allowed most of the digital press manufacturers to bring in new applications for their drum and toner presses and to re-introduce their refined and new versions of inkjet presses. In addition, it was an opportunity to present new digital image enhancement software including AI, and the latest applications that tend to be in the direction of labels and packaging.

For Konica Minolta it was no different and keeping in mind the view of its company in India, several thoughts stand out from the drupa experience. According to Manish Gupta, head of marketing, Konica Minolta India, the company’s drupa stand had several attractions such as automation, software, labelling, flexible packaging, embellishments, and foiling with special emphasis on inkjet-driven technologies. All the digital press manufacturers received great footfall during the show at their sizable stands in Hall 8a and 8b. Their Indian distributors received a strong response from printers and converters focused on digital print and sustainable changes.

Gupta agrees that the show was a significant comeback for commercial printing given all the publicity about it being mostly a packaging show – although the digital press manufacturers were keen to show packaging applications. There was tremendous interest at drupa 24 in book production, including the busy finishing and binding stands in Hall 5 with manufacturers keenly alive to short-run book production relying on digital printing.

Inkjet and the need for speed

At one of the larger stands at the show, KM showed the revamped AccurioJet 60000 its B2-format UV inkjet press (that can run B2 plus sheets as an option) printing at 6,000 B2 impressions an hour, or 3,000 duplex-printed B2 sheets. Double the speed of the current KM-1e, the new inkjet press needs to keep up with the overall need for speed that was visible at the show to optimize the viability of the inkjet sheetfed presses. Based on customer engagements at drupa the company plans the first beta installations in 2025.

Gupta suggests that the show illustrated that inkjet is becoming more effective and efficient than before. “This edition of drupa was better for digital and inkjet-based technologies compared to the previous edition eight years ago,” he says. “In the last edition, digital and inkjet were still new for many countries and there was a lot to explore and discover in several areas. The 8-year gap certainly did push these technologies to be among the more commonly used and understood.”

Konica Minolta India received several sales inquiries and confirmations at drupa for its machines and equipment. “From a technological point of view, we are preparing for many new solutions. We showcased a lot of solutions that we currently have or that we are bringing in the near future. And we were able to communicate many things with live demonstrations and customers face to face so that they can also plan their businesses accordingly,” he adds.

In terms of business growth, the company is looking at all its segments. Gupta said, “We are good and strong in India with more than 50% market share in the commercial printing business, but we still see a lot of opportunities in other segments like labels and packaging. We are doing well in the labels business – however, we see that this segment has better potential in what more [or else] we can offer. Packaging is still new to us, so we are yet to develop in that area.”

He points to the simple PKG 1300 device with an automatic feeder and stacker shown at KM’s stand for printing on folding cartons and corrugated substrates at a high print resolution of 1200 x 1200 at speeds up to 27 meters a minute. He sees the need to evaluate the potential market in India for devices such as the KM AlphaJET for printing and enhancing cartons by moving the substrate from station to station on a conveyor shown at IpackIma in 2022 and shown in a much more elaborate configuration at drupa24. Together with its MGI partner, this device performs all the processes for package printing from inkjet printing to embellishment including spot varnishing, foil stamping and post-processing in one continuous line.

Automation and in-line finishing

Gupta also talks about the need for automation and in-line finishing which is likely to become a bottleneck as digital and commercial printers buy faster and more efficient presses. He mentions the cold lamination device that was demonstrated on the KM AccurioPress 84 Hi-Croma at drupa. The cold lamination of the printed sheet on both sides can be attached in-line to any of the KM digital presses avoiding extra steps and manual handling.

He foresees a workflow management speed breaker ahead when printers have to handle a higher number of jobs in a shift, each with unique prepress, value-added finishing, and binding and trimming requirements. One of his drupa observations is that – “More printers should be thinking about automation, and many are still not.” He points to the several KM in-line automation modules that some local digital printers have acquired that can fold, bind and trim brochures, booklets and books.

Gupta speaks about the multiple options that Konica Minolta showed at drupa and which it has in terms of technologies and consumables such as lasers, inkjet heads, and inks that could be turned into appropriate machines and products for market requirements. Meanwhile, the Indian subsidiary is actively working on how its customers can use and optimize a wider selection of substrates that are available in the local market.“We are currently in the process of testing and certifying media for use in India. The team is already trying to identify what are the machine parameters and basic media types that the customer wants to use,” he said.

*Aayush Pandey with inputs from Naresh Khanna