Xaar and Quantica have signed an agreement that will see Xaar manufacture Quantica’s high viscosity NovoJet printhead at its factory in Huntingdon and will also allow Xaar to sell the NovoJet heads itself.

Just to recap, Quantica, which I’ve covered in a previous story here, is a start-up company based in Berlin that is developing 3D printers for a number of different markets. Quantica’s approach is based around materials jetting – that is using an inkjet printhead to lay down a fluid that is heavily loaded with the final build material. More importantly, Quantica’s vision is for jetting multiple materials – still not that common in 3D printing – to be able to create more complex parts. That led Quantica to develop a printhead that was able to cope with these demands.

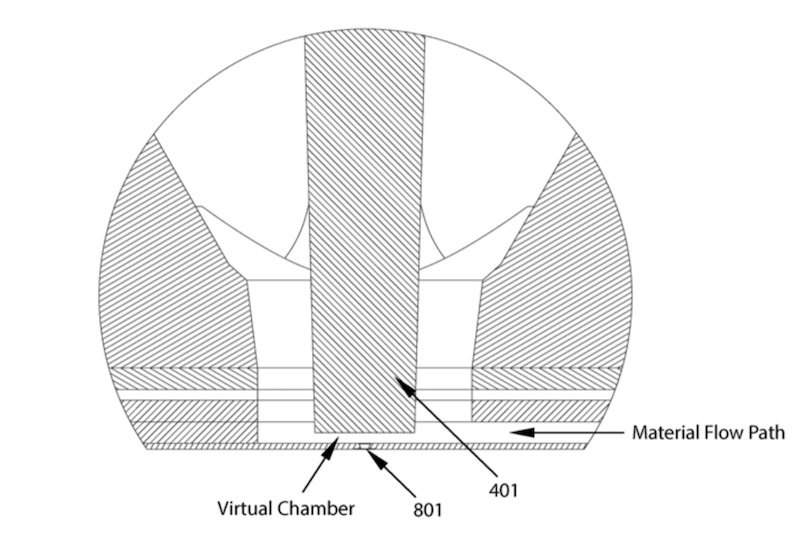

The NovoJet printhead has quite a unique approach, which I’ve written about in more detail here. But essentially, it has a large virtual chamber, made of the space between the nozzle plate and a roof piston with the perimeter open to a local manifold area. This allows for fast refill, even with high viscosity fluids, as well as full recirculation to the back of the nozzles at a high flow rate. In order to jet the fluids the piston is driven hard towards the nozzle, forcing the fluid through the aperture.

Xaar has made much of its ability to print high viscosity fluids – up to 100cP – which it rightly sees as a unique feature given that most inkjet heads struggle above 12cP. The NovoJet can handle fluids at 400cP at jetting conditions, which means temperatures up to 85ºC. Those same fluids will have much higher viscosity at room temperatures. Most printer vendors use temperature to control the viscosity of their fluids, as higher temperatures help to lower the viscosity to make those fluids easier to jet. However, as Ramon Borrell, Quantica’s CTO, points out, there is a limit to how high the temperature can go before this affects the performance of the fluid.

Illustration Quantica

I’ve previously reported that Quantica planned to have its printheads finalised this summer and Borrell says that the company is still expecting to have actual printheads in summer for its internal evaluation and any further refinements before launching the production printer itself towards the end of the year. He adds, “We are optimistic in our design and the manufacture so we don’t expect any surprises.”

Contract manufacturing

Quantica plans to concentrate its efforts on developing solutions for additive manufacturing and is aiming to develop solutions for a number of different markets, including engineering parts, modelling, biomedical and printed electronics. But for now it has concentrated on the dental market.

So the arrangement with Xaar is about ensuring that the NovoJet printheads can be manufactured in scale. It is not practical for a small company like Quantica to invest in the level of equipment needed to manufacture printheads. Xaar, on the other hand, has a state of the art manufacturing plant and has spare capacity having previously scaled up to match the peak of the ceramic boom.

Graham Tweedale, Xaar’s chief operating officer, says that Xaar did not need to invest any further in its manufacturing to handle the NovoJet heads, noting, “We already had capability in Huntingdon that’s very well aligned with producing the Quantica product so we are able to utilise the skills and the experience that we have developed, and the equipment, over the last 15 years in Huntingdon so there’s a really good fit and good synergy.” It’s also worth noting that Quantica was very aware of exactly what facilities Xaar has, since Borrell himself previously worked as CTO at Xaar.

However, there is far more to this arrangement than simply a contract manufacturing agreement. Borrell explains, “It’s a very broad arrangement. It covers manufacturing of course but also it covers Xaar commercialising the printheads. And it’s open for further collaboration, meaning co-development, but the details have not been decided.”

Xaar has not made any investment into Quantica though as Tweedale points out, “We have access to the product and can sell into applications ourselves as well.”

He adds, “In the future we may find there are areas where we collaborate in a different way but for now its using the same heads and taking them into different markets.”

Quantica’s focus has always been on the 3D printing market so this agreement leaves Xaar free to exploit other markets though Tweedale says they will work closely together on how they commercialise the products across all markets. In some areas there may be some overlap. Both companies, for example, are interested in pursuing the textile printing market though Borrell is quick to clarify that Quantica’s interest is in special effects, high fashion and sophisticated finishes for very high value added applications rather than printing patterns to materials. Nonetheless there is some overlap as many digital printer vendors also want to add textures and effects to fabrics and DtG printers. Borrell says that these sort of efforts so far are more accurately described as 2.5D and that Xaar and Quantica will have to figure out where to draw the line to divide this market between them.

Photo Nessan Cleary

Tweedale adds, “We are exploring the full range of applications that can benefit from the additional capability that Quantica offers, and that’s for viscous fluids that currently have no opportunity to exploit the benefits of digital. So areas like industrial coatings, so glues, adhesives, for labels and solar panels, display, general assembly. You can imagine a contract manufacturer who’s doing several gluing operations and you may have different glue laydowns that you need to achieve across different lines. If you could do that digitally you could have a common solution that you could use variable data to cover whatever gluing operation you want. So we see it as a great complementary offering to have to our ImagineX platform to take it into areas with really viscous fluids where people can’t exploit the benefits of digital today.”

This would take Xaar into new territory, going beyond industrial printing and into manufacturing. Tweedale adds, “Industrial coatings, and I would class adhesives in the same way, but anywhere where someone is trying to do a coating or lay down a fluid that is really really viscous where today they are having to do it in an analogue way, where we can convert them to digital and they get the benefits of variable data and reduction of waste and potential to reduce energy – I think all of those areas we will explore to see if there’s a good fit here with the Quantica technology.”

For now there is a single version of the NovoJet but Borrell says that Quantica will expand beyond this, noting, “We have a roadmap of variants. We know that some customers might like derivatives for their own applications that might require some specific changes. But everything is on the table now. And in our roadmap we have several models, as a family of products rather than completely different types of printheads. Its just variations on the same thing.”

Borrell concludes, “It was partly an accident but partly the aim when we started the discussion, is that the two companies that have been most successful in high viscosity jetting so far, joining forces so there is now a very strong capability to deliver any requirement on complex, difficult, viscous, particle size, all these very high value added applications so one way or another we want to be able to provide both of us with a solution.”

In the future, Quantica could also use other parts of Xaar’s portfolio such as the MegnaJet ink supply systems. Borrell says, “The agreement has provisions about this but our first product does not use it because it’s already designed and we did it without any external input but it might be in the future that we combine elements from Xaar beyond printheads based on need.”

Tweedale says that Xaar will be talking with potential customers from now though the actual manufacturing of the NovoJet heads will start later this year to match Quantica’s needs as it prepares to launch its first commercial printer.

Quantica is planning to show its new printer at the Formnext 3D printing show in Frankfurt in November, which will give interested readers an opportunity to see what this technology can do. In the meantime, you can find further details from xaar.com and quantica3d.com.

NB: It’s worth noting that there is one more player in the high viscosity game. Archipelago, which is based in Cambridge, has developed the Powerdrop, that’s capable of jetting fluids up to 2000cP in viscosity and which I will get around to covering later this month.