The Italian research and development lab D-House has been working with Stratasys’ direct-to-textile 3D printing technology to create a new fashion collection, ‘Knitting the future: 3D printing meets Merino wool’, which was developed with The Woolmark Company and is being shown at this week’s Milan Design Week in Italy.

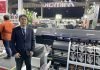

The D-House lab was set up by Dyloan, an Italian manufacturer serving the high-end fashion sector since 1987, and which has a reputation for using new technologies to create new design applications for fashion brands.

Stratasys direct-to-textile 3D printing was first demonstrated at New York Fashion Week in 2019 when the designers threeASFOUR showed the ‘Chro-Morpho’ collection, developed with Travis Fitch, which was inspired by the microscopic colors and light filtering of butterfly and insect wings. Up to this point, 3D-printed elements were printed separately and added to garments later but printing directly to the fabric opens up new possibilities. A Greta-Oto dress from the Chro-Morpho collection, for example, used a Stratasys-engineered lenticular effect to play with light and color. By printing spherical, fish scale-sized cells made of photopolymers directly onto the polyester fabric, the color of the dress shifts with each small movement. The thousands of cells on the dress’s 27 parts consist of a clear lens with strips of color contained inside.

This latest project involves printing directly onto wool, which is an industry first. For this latest collection three international designers and four students from the Royal College of Art in London, supported by several Italian knitters and spinning mills, 3D-printed unique patterns directly onto Merino wool knitwear using the Stratasys PolyJet J850 printer.

The Polyjet technology is tried and tested and essentially involves laying down a liquid photopolymer onto a build tray to build up an object one layer at a time. This then cures to a smooth surface, capable of holding plenty of detail, including simulated surface textures. There’s a good range of materials that can simulate realistic textures like fabric and wood, as well as create glass or plastic-like transparency with smooth color gradients.

Loreto Di Rienzo, one of the founders behind D-House, explains, “What immediately surprised me about this 3D printing technology is the Pantone color accuracy; we can create the required color in extreme fidelity – a non-negotiable when working with fashion creatives.”

He added that the wide range of materials offered more freedom of design, saying, “Not only can we directly 3D print different textures and finishes onto the item, we can also include functional elements to the garment. Having these capabilities allows us to present customers with a range of outstanding aesthetics and highly creative alternatives.”

An example from this collection is Illusion, a jacquard coat with a four-color 3D effect created by designers Vittorio Branchizio and Uroš Mihić in collaboration with Maglificio MAS. The texture of the 3D print, echoing dice, creates the illusion of iridescent shades of color that change depending on the angle they are viewed from. This chromatic effect is down to 3D-printing an array of hollow cubes directly onto the back of the jersey knit coat. They were then arranged in a precise configuration to enable the surfaces to filter color, creating a change in tones and shades. The designers added a thermosetting thread to the 100 percent Merino wool fabric to provide additional structure to the garment.

Di Rienzo says that he is having discussions with several fashion brands on new upcoming projects. The team at D-house is also exploring new production methods for high fashion garments, bags, and shoes, including the combination of direct-to-textile 3D printing with other processes such as thermoforming, as well as the use of the technology to repair vintage garments to further increase sustainability within the industry.

He continues, “3D printing allows us to produce complex design geometries not possible any other way, and my dream is to create a finished garment made entirely with 3D printing.” He adds, “The technology has decorative and functional properties that we are currently exploring, which I have no doubt will enable us to achieve new and unexpected applications. On the materials side, I believe that over the coming years we will not necessarily have to use fabrics. New materials will emerge, and with direct-to-textile 3D printing we will be able to use them to produce a new category of the garment.”

He concludes, “Also, from a sustainability perspective – a key issue in the world of high-end fashion – 3D printing gives us the ability to customize and produce pieces in only the exact quantities needed. This is one of the reasons why we have a close partnership with Stratasys, which is crucial to our business moving forward.”

Naomi Kaempfer, Creative director for Art, Design, and Fashion at Stratasys, commented after the New York show that combining 3D printing with textiles is about working in harmony with materials rather than replacing them, saying at the time, “Soft, lithe fabric touches the skin, while 3D-printed designs adorn the outer garment. This approach, developed through months of collaboration and testing, was the only way to realize the designers’ vision. It brings the intricacy, nuance, and splendor of the dresses to life.”

She says that the company is focusing on producing 3D fashion garments that will be sold commercially in the luxury and haute couture market, adding, “Over the past five years, we’ve seen 3D printing make headlines with our fashion design collections. Collaborating with high-end fashion brands, we are focusing on demonstrating novel computed aesthetics that trigger optical illusions. This, together with highly intelligent 3D design software, is raising the bar with a new design language for the fashion market.”

This article was originally published in Printing and Manufacturing Journal