The Indian book industry has moved through a lot of difficult times and the overall situation is challenging for both book printers as well as publishers at the moment. The objective of the Book Printers and Publishers’ Conclave has been to create a general consensus on issues affecting the Indian book publishing industry, and the ways and means to address them.

Thomas Abraham, managing director of Hachette India, and Ajay Joshi, general manager of planning and production at Penguin encouraged book printers to take digital printing and production of books forward in the country, at the recently held Book Printers and Publishers’ Conclave in New Delhi. Abraham cited research and his own company’s experience, which indicate that there is much scope for digital book printing in India as a large percentage of books printed have print runs below 500. According to Abraham, while the number of bestsellers such as the Harry Potter books are increasing in the Indian market, so are the short runs. As a publisher, he stated that he would like to take advantage of a technology that allows him to take a chance on a wider variety of books with shorter initial print orders.

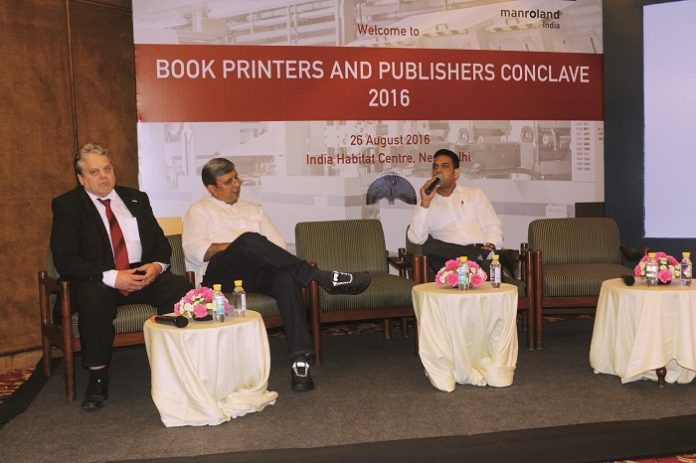

The presentation by Abraham and the panel discussion that included Joshi and Stadler explored the past and current trends in the industry. Reflecting on the current buoyancy of the industry, Abraham lamented the low pricing structure of books in the country where the industry is seen as a noble or charitable activity in the interest of knowledge rather than a business. He said that it would be far better if books were even taxed at the point of sale.

Abraham observed, “In India, books are hugely respected; they are a cultural commodity product. It is not necessarily seen as a profitseeking industry. This cultural thinking process has managed to keep the book prices down so far. The government thinks that it has done its bit by making it a tax-free industry. In my opinion, books should now be taxed although education and trade segments should be separate. Accountability and data are much needed in this industry, which could all come with the introduction of tax.”

Organized by manroland India, the event focused on digital printing and inline production options for the book industry. Opening the proceedings, Sudeep Bhattacharjee, managing director of manroland India said, “manroland web systems has been attending to the needs of the book industry worldwide with its digital inline finishing solutions, which consist of two machines—the FoldLine and the FormerLine.” According to Alwin Stadler, vice president – digital solutions, manroland web systems, instead of offering the customer isolated applications, manroland has connected the complete printing system with its core competencies— folding and workflow technology and networking—and that too from the very beginning of the process.

Stadler in his presentation said that altogether 14 FormerLine and six FoldLine manroland finishing lines have been installed in Asia, Europe and South America, where they are being utilized by book, magazine, newspaper and commercial printers. Mengis Druck in Switzerland produces the digitally printed daily newspaper, Walliser Bote, in the evenings on a FoldLine workfl ow while during the day it produces advertising inserts and other work. Hucais in Dongguan, China focuses on economically viable book production using FormerLines for fi nishing and German book printer CPI sees the FormerLine as an effi cient solution for digital 4-color book production. In Brazil, at the beginning of 2016, the educational book-publishing house FTD Educação started production on a manroland FormerLine while Polish company Legra produces calendars through its FormerLine.

“In India, books are hugely respected; they are a cultural commodity product. It is not necessarily seen as a profitseeking industry. This cultural thinking process has managed to keep the book prices down so far.”

Stadler said, “In the near future, matching systems and workfl ows will be developed and adjusted to market demand. While traditional gravure printing turns into offset printing, more and more production will be digitally printed. Each incoming print job could be checked and immediately assigned to the production unit where it can be produced most economically and effi ciently. Digital printing and offset systems in any printing house can be linked through a MasterQ, which will automate and update job scheduling permanently.” The discussion, moderated by Ramu Ramanathan of PrintWeek India, saw active participation of Abraham, Joshi and Stadler. Joshi spoke about the need for better coordination between publishers and printers, which could help improve the essential balance between demand and supply. Book printers and digital press suppliers attended the event as did Erich Wagner, deputy vice president – sales, manroland web systems. Leading printers including Bhuvnesh Seth of Replika Press, Amila Singhvi of International Printo-Pac, CJ Jassawala, executive director – printing, Thomson Press, and Vasant Goel of Gopsons Printers also participated in the event.

Not many are aware that the leading manufacturer of newspaper and commercial web offset presses, manroland web systems is also a manufacturer of web handling and fi nishing systems for high-volume digital presses. Nevertheless, the company has been quite successful in this activity in the past three years. At the manroland web systems stand at drupa 2016, a digital workfl ow made up of a Kodak Prosper 6000S Hybrid digital press and the manroland FoldLine as a fl exible inline folding unit with many varied product applications were demonstrated. Using the new digital print reel splicer from manroland web systems, pre-printed reels were processed in alternating offset and inkjet modes, and guided to the FoldLine. The stacking of the produced products, such as newspapers, books, booklets and brochures, was taken on by a Rima system. The changeovers between three different successive newspaper versions was demonstrated at top speed on-the-fl y. The individual jobs were connected to become a continuous production run via the MasterQ workfl ow software.