Mitsubishi’s excellent after-sales support coupled with the outstanding performance of Diamondspirit-SA presses has led to the signing of another deal by Malayala Manorama for two more Diamondspirit-SA presses. The two presses may be installed at Malayala Manorama’s Kochi and Thiruvananthapuram plants, respectively.

Mitsubishi Heavy Industries Printing & Packaging Machinery (MHIP&PM) has announced signing of a sales contract with Malayala Manorama, Kottayam for two more Diamondspirit-SA presses. The deal signed by Malayala Manorama comes in quick succession after the successful installation and taking into production of five presses from Mitsubishi in 2013.

Malayala Manorama, a leading Malayalam newspaper with 2.4 million copies, was founded in 1888 by Kandathil Varghese Mappilai in Kottayam, Kerala, India. It began as a 4-page weekly newspaper, which was published every Saturday. The weekly newspaper became a bi-weekly in 1901, a tri-weekly in 1918, and a daily in 1928. Malayala Manorama took the first Diamondspirit-SA press into production as early as November 2014, while the fifth press has been in operation since June 2016. By signing this latest deal, Malayala Manorama has reinstated its confidence on the performance of Diamondspirit-SA as well as the project management capabilities of the Mitsubishi team.

Speaking on the deal, Mammen Mathew, chief editor and managing director of Malayala Manorama said, “We ordered five Mitsubishi Diamondspirit-SA presses in 2013 and all of them have been performing exceedingly well in terms of print quality, reduced wastage and productivity. Mitsubishi has also provided excellent after-sales support. We had no hesitation in placing our order for two more presses at a very competitive price.”

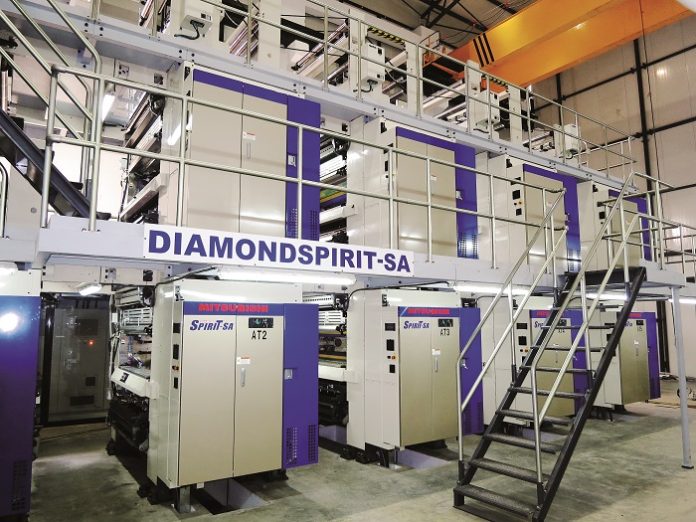

The Diamondspirit-SA for Malayala Manorama is capable of printing a 40-page newspaper up to 75,000 copies per hour. In contrast with the Diamondspirit, which features two-page around blanket cylinders that transfer the print image to paper, the DiamondspiritSA features one-page around blanket cylinders, which allows to reduce the height of the printing unit by 20% and the weight of the printing unit by 30%. The compact press design realizes 20% savings in power consumption. In addition, the Diamondspirit-SA features a Soft Stop function, which stops the press moderately in the event of power failure, without any web breaks.

In a recent interview with IPP, George Jacob, executive director, Malayala Manorama, had indicated that in total four presses would be ordered in the fourth expansion phase, two of them being new and the other two second hand. One of the two new Mitsubishi presses that have been ordered could be installed at the Thiruvananthapuram plant as it is the company’s only plant, out of 11, that has not had its press lines modernized in previous phases. The Kochi plant could also get one of the new presses as the plant is approaching full capacity at 360,000 copies.