Revitalized manufacturer to showcase its Evolutionary press with more than 250 incremental enhancements and improvements as it pursues its goal of future-proofing offset printing. Patrick Howard visits the Offenbach foundry and factory.

Manroland Sheetfed has turned into a lean manufacturing machine under the energetic management of UK entrepreneur, Tony Langley. Since taking the helm in 2012 of what at the time he describes as ‘a lumbering leviathan,’ he has consolidated its manufacturing into one plant, sold off surplus building and machinery, and brought staff numbers down to 1,600 worldwide. He describes the process as adjusting production capacity to meet the market and derides his two German competitors as continuing to ‘languish [while] their re-alignment of capacity to current demands remains glacially slow.’

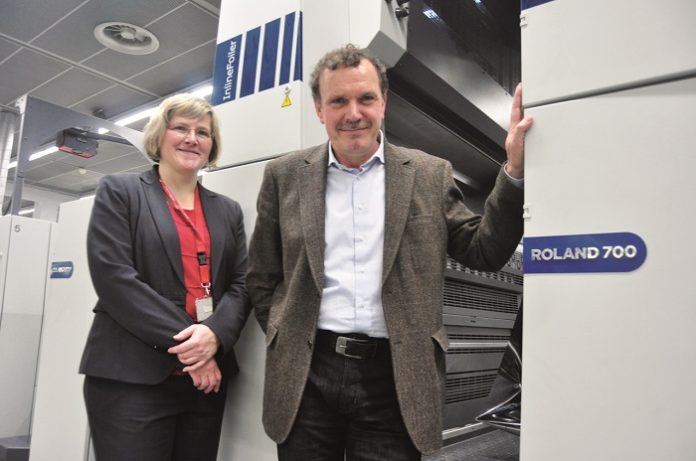

It’s a very different way of doing business for German industry and Langley’s free-wheeling English style has undoubtedly put a few noses out of joint. But more importantly is the attitude of the workforce to their Anglo saviour. Talking with long-term employees, Willie Graef and Hieke Weber, on a cold afternoon in the Southern Germany manufacturing town it is apparent that far from resenting the Englishman’s takeover, they see it as a very welcome intervention. Following the trauma of downsizing and bankruptcy, the iconic German press manufacturer has regained its spirit with both staff morale and results looking better. According to Langley’s annual report it’s in the black, making money as well as printing presses, even if it does operate in a very reduced market.

Long recognized for the high-end manufacturing quality of its machines, which include some of the largest and most complex custom-built in-line presses in the world – the Ultimas, Manroland Sheetfed has tied its destiny to evolving offset technology to meet the challenges of the digital age. At drupa where Heidelberg is launching its Primefire inkjet, Manroland Sheetfed is focussing its admittedly much smaller R&D budget on fine-tuning the product line for greater productivity.

Although the exact configuration of the drupa press was revealed to me confidentially, it will be an Evolution 700, at least a 6-color with in-line foiling. What’s under wraps are the improvements to the feeder. This is the press that was launched in late 2014 with the first Australian installation going to Labelmakers in Melbourne this year.

The Evolution press with its sleek curved look won a sought-after Red Dot Award for design. While it undeniably looks schmick, what is less obvious is what’s under the hood, where the company is confident it has an edge on the competition in terms of production processes. It will also be the nearest thing any offset press manufacturer will have to bringing a ‘new’ press to drupa.

According to Graef, head of printing technology, much of the improvements are invisible, such as in a rewriting of the system software to future-proof it for at least 20 years. The result is an operating system that can be evolved over time in the constant search for improvements. Many of these improvements are incremental adjustments, in keeping with Graef’s stated belief that offset is not about to radically change; it is a very mature technology. But it can be improved and that is the Manroland evolutionary strategy.

There are no plans to develop a digital press, a la Heidelberg, or to branch out into other sectors. The addition of Kodak Stream inkjet marking in the feeder and an Atlantic Zeizer marking station at the coater, are both designed to deliver 100% guarantee of accuracy in high-end packaging. The aim is not only to pick up the tiniest errors in the packaging print but also to save on waste where only the wrongly printed box on a sheet is rejected, not the whole sheet.

The presses use all types of drying with LED UV claiming much of the attention. But Graef is circumspect in promoting it as the ‘be all’ curing technology of the future. He believes there are other developments to come and that the health and environmental requirements of the packaging sector will limit the use of LED UV. A satisfactory coating formula that can be used without turning yellow is still to be found.

Manroland Sheetfed continues to dominate in the long-form custommade packaging presses that are virtual standalone factory lines. They can be up to 36 metres long with multiple coating and printing units in addition to foiling and extended driers. The numbers are not very large but the steady return of customers looking for the next generation says a lot about Manroland’s technology reputation.

The future of offset printing is assured for the foreseeable future. What’s less certain is the fate of the offset press manufacturers. They all Wilhelm Graeff, head of print technology (left) and Stefan Finger, head of research and development at Offenbach have to chart their own destinies and Langley believes that a ‘right sized’ Manroland Sheetfed with its cost base in order is capable of meeting the requirements of its customers indefinitely.