As the newspaper industry comes to terms with its challenges there will be extreme pressure to produce higher quality color pages on thinner newsprint and at a lower cost both monetarily and in terms of the environment or carbon footprint. The worldwide demand for double width presses — both 4 x 2 and 4 x1 has dwindled and these machines cannot be sustainably produced by the seven manufacturers who have been making these and even bigger web off- set presses.

Even the demand for 2 x 1 presses in India has been poor over the past two years although some industry experts expect an uptick in the 2015-16 finan- cial year from newspapers — openly called the Modi effect. While we expect that some of the wiser press manufac- turers may turn their attention to other engineering manufacturing ventures, the quality press manufacturers in India have the benefit of both a real market and good access to high technology for creating high automated and environmentally friendly presses and press- rooms.

Strong global suppliers for automation such as Seimens and B&R and Rock- well; water filtration and ink supply sys- tems from Lincoln Helios and Techno- trans; dampening solution circulators, filtrations systems and spray dampening bars are available from Technotrans and have been incorporated on both single width and double width presses made in

the country; reliable autopasters are made by Manugraph and are available for other manufacturers and export from Megtec. Automated registrations systems are available from Quadtech and QI and numerous others including new- ly developed domestic manufacturers. And there are several solution providers of environmental solutions for press buildings including Megtec which now derives most of its revenue in India from this segment.

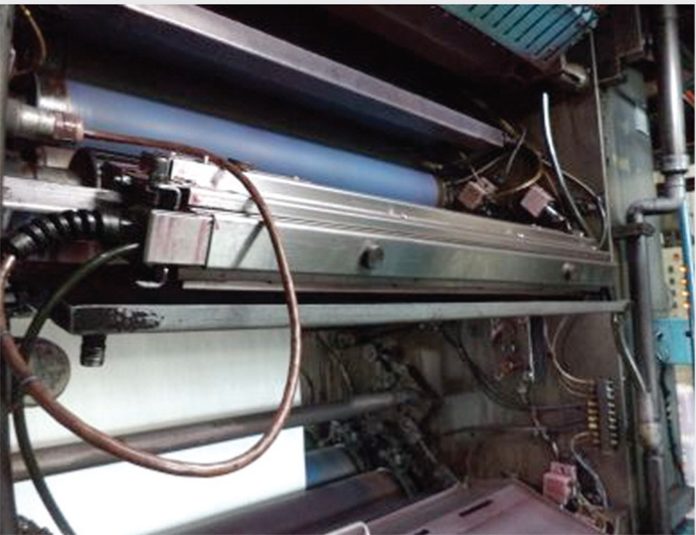

Using contact-free transfer of the dampening solution with high, con- trolled spray frequency using spray bars is one of the best ways to decrease the dampening solution and to print brighter wet on web printing with faster and better drying. The new spray bars allow precise dozing with individual ac- tivation of each spray nozzle and the newer modular designs provide in- creased service life and easier mainte- nance and nozzle cleaning without com-

plicated tools.