Over the past decade, inkjet technology has quietly but decisively moved beyond its traditional role in home, office, and commercial printing. Today, it is emerging as a critical enabler across a wide range of industrial applications, spanning textiles, labels, packaging, electronics, and even renewable energy. According to Ramprasad SM, general manager of sales and marketing OEM products and solutions at Epson India, this transformation is being driven not just by global innovation, but increasingly by Indian manufacturers who are adapting inkjet technology to local needs and exporting those solutions worldwide.

Present for over 30 years in India, Epson’s current focus in the country sees it not just as a destination for sales, but as a hub for innovation, localization, and manufacturing. In our online interaction with Ramprasad, he explained how the company is enabling Indian manufacturers to develop advanced production systems for both domestic and global markets using its inkjet technology.

According to him, the past decade has seen a decisive shift: “Inkjet has now expanded into the industrial segment, where it is no longer viewed as a replacement for conventional processes such as offset, flexo, or gravure, but as a complementary technology that enhances these.”

Hybrid printing and retrofitting

The shift in perception has widened Epson’s growth in the country, as its inkjet solutions are increasingly being integrated into conventional production lines, allowing printers and converters to retain speed and cost efficiency while adding digital flexibility. One of the strongest indicators of industrial inkjet adoption in India is the growing use of retrofitted inkjet modules on existing presses. Epson’s printhead portfolio has enabled hybrid configurations across multiple industries.

In our interaction, Ramprasad noted that in textiles, where screen and rotary screen printing dominate volume production, Epson’s S3200 A1 aqueous printheads are being deployed as digital units within conventional systems. This allows manufacturers to print variable designs, complex patterns, and expanded color ranges digitally, while continuing to rely on screen printing for base production. The result is a balanced combination of cost efficiency, speed, and creative freedom.

He further pointed out that a similar approach is gaining momentum in labels and flexible packaging, where Epson’s I3200 UV series printheads are widely used in inline retrofitting applications alongside flexo, gravure, and offset presses. These digital modules are used for spot colors, variable data, embellishments, varnish effects, and decorative finishes, enabling converters to meet growing demand for premium and customized packaging.

While some digital embellishment solutions operate as offline systems, Ramprasad noted that Epson is seeing increasing interest in inline retrofitting, where inkjet becomes an integral part of the production workflow. Several such retrofit installations are already operational in the country.

Partnering with India’s OEM ecosystem

A key pillar of Epson’s India strategy is its collaboration with local OEMs. Epson is currently working with approximately 30 OEM partners in India, spanning packaging, labels, textiles, graphics, and signage. “The partnership goes beyond supplying printheads,” he says.

Ramprasad said that Indian OEMs, many of whom began as print service providers, are leveraging Epson’s inkjet heads to develop complete machines, from textile printers and corrugated board presses to web-fed digital presses. Epson supports these manufacturers with application know-how such as electronics integration, ink compatibility testing, and system optimization, helping them shorten development cycles and improve reliability as well as the time to market.

In the web-fed segment, Epson inkjet technology is enabling Indian manufacturers to enter the growing print-on-demand market. High-speed digital web presses operating at 70-80 meters per minute are already being built and installed, catering to educational publishing, short-run books, and transactional printing.

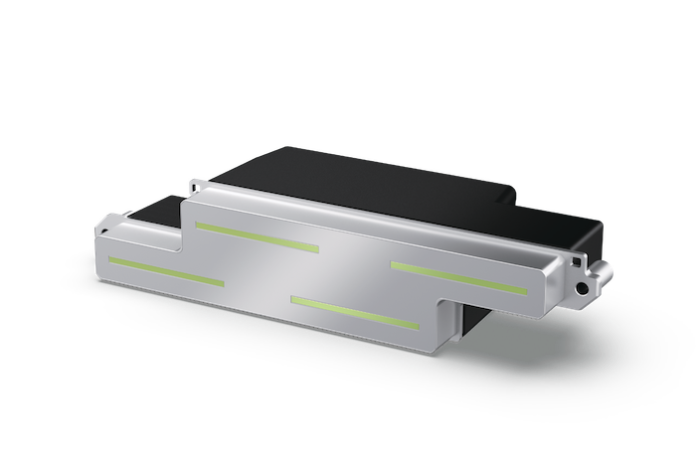

Ramprasad says that while early systems largely used Epson’s i-Series printheads, demand for higher speed and resolution accelerated the adoption of the D3000 series. Available in both aqueous and UV versions, the D3000 offers 1200 x 1200 dpi single-pass printing and is emerging as a reference standard for high-quality narrow-web label presses globally.

Beyond print

Epson’s industrial inkjet roadmap in India extends well beyond traditional print applications. In the electronics sector, particularly printed circuit boards (PCBs), Epson’s S800 series industrial printheads are being explored for use with conductive and metallic inks, enabling digital deposition of functional materials.

Another area that Ramprasad explored in the discussion is printed solar technology, where inkjet is used to manufacture thin-film, flexible solar panels using perovskite-based materials. These panels offer advantages in flexibility, weight, and logistics compared to conventional crystalline solar modules. While still at an early stage in India, Epson is actively engaging with stakeholders exploring the local market potential of this technology.

Additionally, the company sees long-term potential in direct-to-shape (DTS) printing, which combines inkjet with robotics to print directly onto three-dimensional objects such as bottles and containers. Although adoption in India is new, the technology is already established in Europe and North America, and aligns well with future trends in custom packaging.

In our conversation, Ramprasad emphasized that Epson has been helping Indian manufacturers move up the value chain from users of technology to creators of export-ready industrial systems.