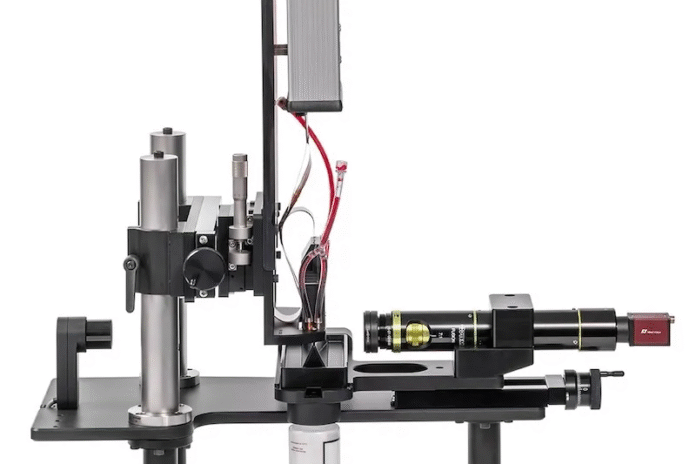

Meteor Inkjet, which mainly develops printhead drive electronics, has enhanced its drop watching systems with the introduction of its advanced DropWatcher optics, which promise more precise visualization and measurement of ink droplets.

Drop watchers are widely used in the development of inkjet printing systems to evaluate the way that the individual ink drops are jetted – typically for the volume, shape, and velocity of those drops – in order to optimize the combination of printhead, fluid, and electronics. Some vendors, notably ImageXpert, provide complete systems; however, Meteor’s approach has been to offer components that its OEM customers can integrate into their own dropwatchers, print test stations or inkjet devices.

A drop watching system is based around high-speed strobe lights and cameras to capture images of the drops in flight. Previous generations of Meteor DropWatchers operated by synchronising the strobe with the printhead firing frequency, using a long exposure. This technique produced high-contrast images representing the average drop position and velocity, but any variation or jitter in the velocity or trajectory of the droplets would blur their edges.

It obviously follows that sharper, higher resolution images make it easier to accurately calculate drop volume or to analyse dynamic behaviours such as the way that the ligaments might break up, any oscillation of the meniscus and the build-up of any ink mist. Any issues with the sharpness of those images would force researchers to rely on the consistency of drop behaviour, which in turn would affect the precision of their measurements.

The new system gets around these issues by using a high-intensity strobe with addressable pulse outputs and a fixed objective camera lens for better image quality and resolution. This gives precise control over both strobe and camera exposure timings, enabling the user to observe the formation of an inkjet drop and the elements of its creation that affect the print quality.

Each frame captions a single event that shows how each nozzle and each firing cycle can result in dynamic differences in drop and satellite formation. These differences depend on the print frequency, nozzle duty, and the chemical composition of the formulation.

Clive Ayling, managing director of Meteor Inkjet, explains, “The new dropwatcher technology is a change in both hardware and software.” He adds: “The new components use fixed lenses. We offer various options to obtain a selection of magnifications.”

The enhanced optics enable users to visualise the tiniest femtolitre (fL) drop sizes, making it possible to observe and reduce misting through optimising their waveforms. It follows that by minimising the mist formation, developers can prevent nozzle plate wetting and obscuration, and therefore deviations in printing as well as missing nozzle artefacts.

The new optics are also capable of analysing the first ejected drops after any idle period, whether it’s microseconds, minutes, or hours. During those inactive times, ink may dry in the nozzles or the nozzles may not fill with ink. To counter these problems, a tickle pulse or pre-pulse can be added to the waveform. Eliminating these problems can reduce the need for maintenance and cleaning cycles, which can save time and operator training, as well as reduce substrate wastage and lead to a more sustainable and cost-effective print solution.

Jonathan Wilson, Meteor’s vice president of Sales, comments, “With our new DropWatcher optics, you can see and measure droplet behaviour with a level of precision that simply wasn’t possible before. This breakthrough enables our customers to fine-tune their print systems with unprecedented accuracy, leading to measurable improvements in print quality, process reliability, and efficiency.”

Ayling adds, “Existing users of the previous Meteor DropWatcher technology can purchase an upgrade kit comprising only the items they would need to replace and the new software.”

The new system and the upgrade kits are available now, with Ayling saying, “It is not a big price change.”