Epson showed off a prototype Direct-to-Shape printer earlier this summer at the Automatica show in Munich, Germany. This is interesting, partly because it would be Epson’s first move into the DtS market, but also because it appears to have come mainly from Epson’s industrial robot division.

One of the difficulties in designing DtS printers is that inkjet printheads work best when they are close to the surface. That’s not a problem when working with flat uniform substrates like paper, but it’s a challenge with objects that may have complex shapes. That has meant that most DtS printers are limited to particular shapes such as cylinders.

The obvious solution is to use robotics to allow the printheads to follow the shape of the object being printed. Heidelberg tried exactly this approach a few years ago with its Jetmaster Dimension-series of DtS printers, later renamed Omnifire. Heidelberg started with the reasonably compact Omnifire 250, based around four axis of movement, before moving to the much larger and more expensive Omnifire 1000, with six axis of movement. Heidelberg managed to sell several of these before giving up on the project.

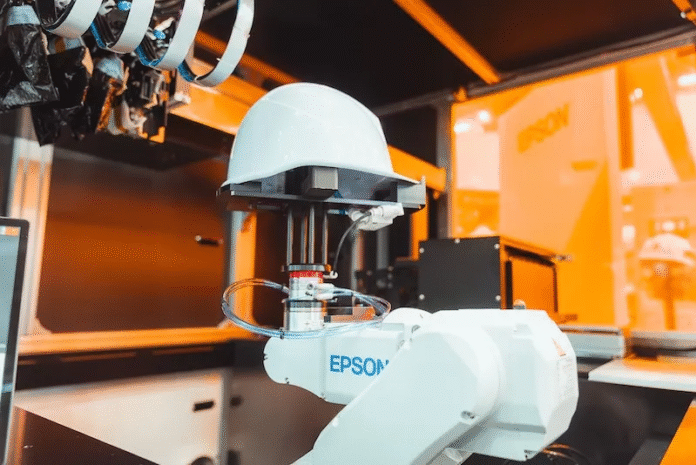

Fast forward a few years, and the cost of robotics has started to come down. Epson already has a division that specialises in industrial robotics and has been quietly tinkering with using this to create a DtS printer for some years now. The solution that Epson has put together uses five printheads, for CMYK plus white, though Epson says these can also be customised. Each head is mounted on its own mechanism, which can be raised up and down to ensure the head is at the optimum height for the object shape, which may be all the movement needed for some objects. For more complex shapes, the solution also includes a six-axis robotic arm that can hold the object to be printed on, twist and turning it to present different aspects to the printheads.

Epson has used its S800 PrecisionCore printhead, which is built around a single PrecisionCore chip, giving it a rectangular shape. The PrecisionCore chips have two rows of 400 nozzles tightly packed together on a 33.8 mm line, which gives an effective density of 600 nozzles per inch. It’s a very compact design, which is essential for DtS machines because of the need to get the printhead around irregular shapes.

This could include, for example, helmets for industrial or road safety use, automotive parts or sporting equipment. Epson also sees a market for functional printing, such as the printing of sensors with conductive ink, as well as for coating various objects. This suggests that Epson is hoping to go beyond short-run after-market decorative printing and to target the point of manufacture. That in turn means that the key to the success of this printer lies not in the printer itself, but in how easily it can be integrated into a manufacturing line.

So, although the printer has only just been shown off in Europe, Epson has been quietly testing this printer at its Fujimi Inkjet Innovation Lab in Nagano, Japan. This lab, which first opened in 2019, was re-equipped in 2022 with several of these DtS inkjet printers. This is part of Epson’s strategy to expand applications for printhead-based solutions by developing new industrial markets.

Epson has said that it will now begin full-scale global commercialisation. The unit demonstrated in Munich has been installed at Epson Deutschland GmbH, providing a test and evaluation environment for the sort of substrates and applications that European customers come up with, and to give Epson a better understanding of the requirements for implementation.

Epson also says that it is actively pursuing global partnerships for the commercial deployment of this technology. Epson’s play here is that it can supply a complete solution, including the ink, image processing, and after-sales support, as well as developing the hardware, with expertise in both printing and robotics. Epson also offers operational assistance in collaboration with optimal partners.

First published on Printing and Manufacturing Journal

Republished with permission