Colorware has introduced MeasureColor 16, an easyto-use device independent color management tool for any print process and any type of user. Print quality can be measured and improved without wasting time or material. MeasureColor 16, the successor of Colorware’s color management solution PressView, optimizes color management and reduces makeready time. Moreover, it offers an improved intuitive user interface.

Although there is first class and complex technology under the hood, working with MeasureColor 16 is easy. The software has a bespoke user interface for every type of user, based on integrated user profiles. The user has access to all the functionality and data. However, only relevant information is displayed on the screen based on this user profile. This concept makes working with MeasureColor 16 easy for everyone, whether you are an operator or a quality manager.

MeasureColor 16 is a network based solution. All data is stored on the user’s own server, which makes analysis very simple and prevents any discussion about ownership of the data. Data can be shared with any other color management solution in the market. It can be exported to a variety of formats for use in other external applications and systems. Also PantoneLIVE, the cloud based custom color library, is fully integrated.

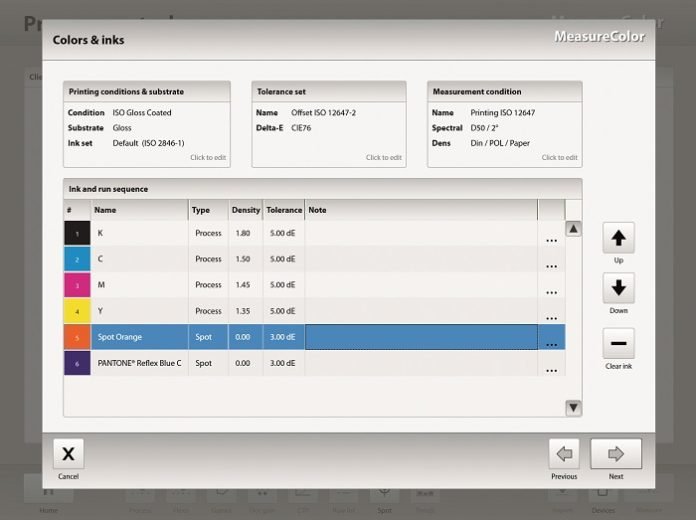

The software can now also be connected to management information systems and ERP systems. This makes it possible to automatically create jobs in MeasureColor 16, which supports open standards and tightly integrates with print quality management solutions. It also supports all the industry leading spectrophotometers, which makes it easy to implement in an existing working environment.

MeasureColor 16 uses Colorware’s ChromaTrack technology which is the perfect solution to avoid unnecessary discussions or guesswork. When on press color matching turns out to be problematic, MeasureColor 16 gives a clear overview, both visually and in writing, of the causes of the problem and how to solve it. If the instructions indicate that a different ink is needed, data can be directly exported to any ink formulation system. To prevent errors from occurring twice the information is stored in the database and presented in the case of a repeat order.