Prinect technology is key to the company’s integrated pressroom, to its customizable web portal for MIS and production and to a multitude of cloud based data gathering and performance monitoring tools. While Prinect provides workflow software for the Smart Print Factory, its new offerings increasingly build automated and two-way communication between the company and its customers. Heidelberg’s Prinect is also at the heart of its new 7-color digital developments such as the Gallus Labelfire 340 inkjet press which will be ready for sale in April 2016 and shown at drupa 2016, as well as the Heidelberg Primefire 106 inkjet that will be shown at drupa but will take perhaps one or two years to come to market. – Editor

Hopes are high within the company that Prinect technology will turn Heidelberg into a truly digital player. Prinect is the heart of Heidelberg’s ‘Smart Integration’ strategy to deliver digital services to its customers. Smart Integration incorporates web technologies, MIS, prepress, press and postpress to provide bespoke print products, with mass production pricing. This takes us away from the ‘walk, talk and paper’ model that existed pre-web towards an industrialized model with smart factories dominated by ‘cyber-physical systems’ where printers are industrialized specialists. Prinect underpins Heidelberg’s concept of a Smart Factory with the press ‘an autonomous, high-tech production working cell . . . a cyber-physical system’ at its centre whether it’s a Speedmaster or a Linoprint digital press. (The Linoprints are Ricoh engines configured with the Prinect DFE rather than an EFI Fiery and Heidelberg has sold over 650 of them. Henceforth these Ricoh engines will be called Versafire in the Heidelberg portfolio. In February Heidelberg said it had sold more than 1,000 Ricoh engines.)

It’s hard to express just how geeky Heidelberg is becoming. People speak of data analysis and autonomy, of using real time data processed in the cloud for Overall Equipment Effectiveness (OEE) benchmarking and using digital simulation to anticipate what will be required to guarantee the most efficient and profitable production possible. The language is far from that of a traditional press manufacturer. Heidelberg is doing its best to live up to this rhetoric especially when it comes to Prinect, both the Prinect DFE (see https://spindrift.click/conventionalprinting/heidelbergdruckmaschinen- . . . , Prinect Automation and Prinect Smart Integration).

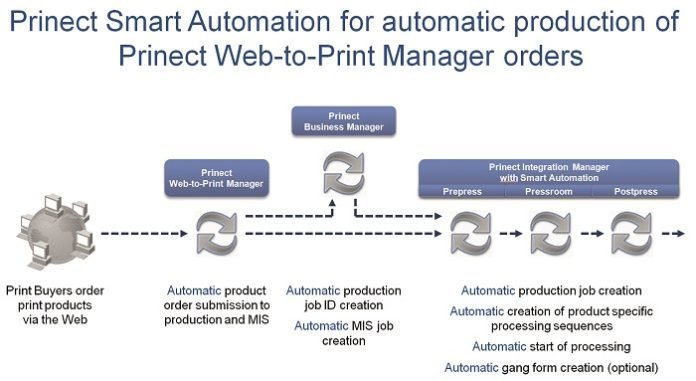

Prinect Smart Automation

Smart Automation marks Heidelberg’s move to sell software independent of the press. The technology selects the best output process depending on production data, such as the number of pages and copies, colors, output format and so on. It will use content analysis to support further automation starting with templates that include the required processing steps, to develop final process nets and imposition layouts for the selected print method, analogue or digital.

Prinect Smart Integration

Prinect Smart Integration is based on four areas of interest all linked using JDF and perpetual data analysis of everything that could possibly have anything to do with print media production, from consumables costs to color management. Prinect Portal, Prinect Production, Prinect Media and Prinect Business together can touch all parts of a printing business.

Prinect Smart Integration will be showcased at drupa 2016 emphasizing data collection with tools for customized workflows, both packaging and commercial. Some of this can be extremely sophisticated such as the development of long-term color reports for monitoring press behaviours like dot gain on a given unit over time. In the US, Grafika a third generation family-owned printing business with US$ 28 million in turnover and 110 employees, recently installed a Heidelberg XL106 with Image Control press control software and Prinect. Prepress manager Mike Hartman said, “The automation for adding marks, importing CAD information are the best things about Prinect Packaging Pro . . . we’re presetting data and sending information back to prepress to analyze the press’s performance.” Grafika will extend the system to the MIS when using Prinect data. Makeready on Grafika’s Speedmaster has gone from 90 to 30 minutes. Ninety minutes for makeready is a rather long time these days. Thirty minutes or less is what we would expect for any printer that has implemented CIP3/JDF and has a modern press. Hopefully Grafika will see yet further reductions with Prinect. A Versafire (Linoprint) digital press is being installed for short-run work.

Prinect Portal

Key to these Smart concepts is full exploitation of the Internet both for communications and as a home for cloud services. Heidelberg has worked hard to up the performance of its online tools, as will be evident at drupa. Prinect Portal V17 is a browser based tool written in HTML5, for handling print orders. It shares much in common with similar products from competitors, such as proofing and approvals and views of production status. Unique to Heidelberg is the fact that Prinect Portal has a single managed customer login to both MIS and production. Customers can see delivery and invoicing details, and an overview of complete projects, from the desktop or mobile devices. Portal views can be customized to individual print buyers. Prinect WebShop is a Software as a Service (SaaS) starter product integrated into Prinect. This is a basic tool printers can offer their customers as a branded portal. Based on PageFlex, the latest version is due for release in July 2016 and will be demonstrated at drupa.

Prinect Production

Prinect Production tools have been updated to include automatic paper stretch compensation which can reduce plate consumption and tighten up makeready times. The software adjusts imaging data according to a paper’s stretch characteristics, instead of operators having to make mechanical adjustments on press. Doing this in software saves time and consumables because plates don’t need to be remade, and on-press because the plates are right and don’t need further adjustments. It’s possible manually to fiddle with the data prior to plate imaging, but this takes time and expertise. Fixing it in software makes much more sense and yields predictable results.

Prinect Media Manager

Prinect Media Manager has been around for a couple of years and Heidelberg says it has five to ten Media Manager customers. It is basically a Digital Asset Management (DAM) system with a user interface that provides a bridge to publishers, so that printers can offer cross media services. The technology is undergoing a major revamp to improve current constraints, such as limited ordering flexibility, and is currently in field test. Heidelberg is expanding Prinect Media Manager’s scope and providing additional services in the cloud including performance benchmarking and software updates. Prinect Media Manager is due to be available in July and will be demonstrated at drupa.

Prinect Business Manager

Prinect Business Manager has also been around for a while and is Heidelberg’s MIS. However using JDF and XML to handle interactionsfor nonHeidelberg system components, Heidelberg has much more in mind for Prinect Business Manager. Thisisthe first time Heidelberg has gone for such an integrated data processing model and the company intendsto go beyond what competitors have done. Prinect Business Manager reachesinto all company departmentsincluding finance, human resources, production, sales and logistics. Calculationsin this uber-MIS track costs, margins, revenue and performance acrossthe whole enterprise. When customers allow, Heidelberg is also capturing their data, so that companies can track their performance within the Heidelberg cohort.

drupa expectations

Prinect Smart Integration will be showcased at drupa 2016 emphasizing data collection with tools for customized workflows, both packaging and commercial. There will be a variety of additions. The new Prinect Cockpit presents the job list with job notes that operators can configure, and will support two monitors. Prinect Sigma Station is being updated to have same the interface design as Cockpit with other improvements such as simplified ganging.

Heidelberg has also enhanced its already impressive color management tools, with space saving color control. Its resized 6 mm color bar takes less space and can be positioned in empty areas of a tightly packed sheet or mini spots can be printed on unused areas and colors can also be measured in the image. Quality management reports can confirm that tolerances are met, including meeting those of ISO 12647- 2. A new feature for the Renderer is spectral measurement of spot colors so that they can be printed CMYK.

There will be a version of Prinect Sigma for packaging to automate positioning, optimize space and avoid waste. It saves plates and makeready and on the new Primefire 106 inkjet press, being developed in cooperation with Fujifilm, will aid automation. The software includes reports available via browser of whatever users want, and all of it is available to the MIS.

PDF Toolbox is a collection of Acrobat plug-ins for editing PDFs. The 2016 version will include additional trapping tools, such as transparency trapping, support for PDF VT with a VT document editor and PDF Compare, a new tool for analyzing PDFs. PDF Compare superimposes two PDFs to identify data deviations in 1-up layouts, compared to the processed PDF, including inaccuracies in structural designs.

Prinect Archive Pro will debut at drupa. It replaces Prinect Content System in 2018 for which Heidelberg has around 50 customers in Europe. Other stuff to watch out for at drupa 2016 includes modular pricing, which is currently under consideration. There are also changes to the Prinect Maintenance Centre, which currently has some 2,200 users. Heidelberg is also expanding its web portal for Prinect users to include the latest news on modules, service requirements, electronic assistance, training documents and FAQs. Heidelberg is also considering a ten-day classroom training programme for experienced users. The Prinect Certified Specialists training includes integration training and is mooted to cost 5,900 Euros. And there’s certain to be more than this come drupa 2016.

Heidelberg’s not alone in the reinvention game. From platesettersto scanners, the graphicsindustry has been upended and traditional players have had to find new revenue streams. Digital printing has proved a rich seam, but the pressis only part of the model. Heidelberg’ssoftware and services direction is more than a toe-in-thewater gamble. The latest financials are looking good, along with Heidelberg’s prospectsfor the future.