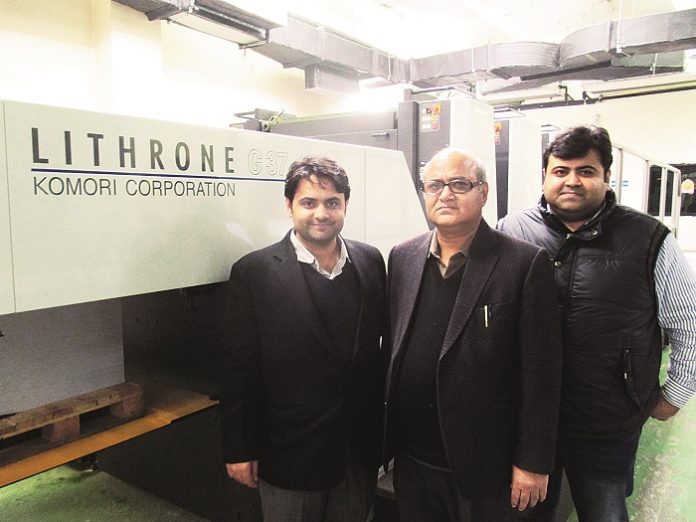

Haryana-based Lakshmi Printographics recently got a makeover when it decided to invest in modernizing its plant in Rai and bringing in many technologies new to the Indian domain to deliver high-quality prints to its customers. In September 2016, the company installed a 4-color Komori GL37 press and a Potevio-Eastcom DX 1160 CtP complemented by a D&J processor with ZAC system. The complete CtP system was supplied and installed by Fujifilm. In addition, the company also installed a plate punching machine from Noida-based Rado Packaging Machines.

Established about 25 years ago, Lakshmi is the first print company in India to boost its plate processing unit with a ZAC-based CtP system. Lakshmi Printographics offers comprehensive design, prepress and printing solutions to a wide range of corporate clients. “We believe in quality and consistency in print production and delivery,” quips Himanshu Nagpal of Lakshmi Printographics. “We have an office in Rajeev Chowk area in Delhi, where most of our graphical and creative design work is done. Our presence at such a prime location in Delhi helps us remain in touch with costumer expectations, service quality and speed.”

According to Nagpal, the ZAC system helps in getting rid of scumming—the accumulation of sticky ink on a plate—and never allows the chemical to overshoot the required pH level. The dot ratings are also very high as compared to CtP systems without ZAC. Scumming, commonly referred to as greasing, is characterized by the dispersion of ink pigment particles in the fountain solution, which increases with the rise in temperature. Lakshmi processes about 2000 thermal plates, all from Fujifilm, every month. ZAC processors are compatible with Fujifilm’s low chemistry thermal plates, significantly reducing chemistry consumption and maintenance through unique intelligent monitoring and replenishment. Each processor in the range incorporates Fujifilm’s unique intelligent ZAC microprocessor control system, which helps achieve consistent, high-quality plate production with minimal chemistry usage and maintenance.

The newly installed 4-color Komori GL 37 is a 25 x 37 inch press with speeds up to 15,000 sheets per hour for sheet thicknesses of 0.04 to 0.6 mm. “We wanted to upgrade our pressroom with a heavy-duty press and the Komori GL37 best suited our requirements. Also, the maximum sheet size of 640 x 940 mm accommodates a wide range of our printing needs,” says Nagpal. The press accommodates short turnarounds, short runs of many different products and on-press proofing. Lakshmi produces about 2 lakh books per month. Print orders are predominantly short runs, with each short run averaging 500 copies of books every month.

The new Komori is further integrated with an offset plate resister punch system—TY200P— for achieving plate-to-plate register control before mounting the plates on the press, and thus achieving high print register in less time. Fitted with CCD camera and display units, the punch machine comes with a pneumatic punching system. “Offset plate resister punch is inevitable if you want to save makeready time, especially when you do a lot of shortrun jobs. Our plate mounting time has come down drastically,” Nagpal informs. “ TY200P can accept all offset plates up to size IV width.