Founded in 2004 and led by its CEO Vishal Goel, KDS (Kwaliteit De Servici) operates across four distinct business verticals – paper rolls, wire cables, handicrafts, and food products. Headquartered in Greater Noida, Uttar Pradesh, the company has grown from a single-product company to a multi-vertical organization serving customers across India.

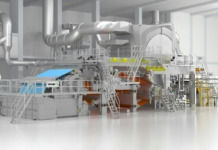

Today it operates two dedicated paper roll manufacturing units in Greater Noida and Vasai near Mumbai. “We started by manufacturing paper rolls used for banking ATMs, billing machines, and all kinds of POS verticals,” says Goel, highlighting the company’s early days.

KDS manufactures a comprehensive range of paper rolls for ATMs, cash deposit machines, credit card terminals, POS systems, hospitals, toll plazas, petrol pumps, ration shops, and transport ticketing systems. “Paper roll is used everywhere in many verticals,” Goel notes.

Photo- IPP

In banking, the company supplies rolls used for transaction receipts in ATM and cash deposit machines. In retail and hospitality, its POS rolls serve department stores, restaurants, and fuel stations. The healthcare sector relies on specialized rolls for ECG machines and diagnostic equipment. Despite being categorized as a ‘functional’ print product, the segment plays a critical operational role across industries.

While digitalization has reduced the visible importance of print, Goel believes the segment remains resilient. “Because of digitalization, the printing aspect is drastically reduced,” he admits. “But hard copy is always a kick. Whenever we have a hard copy, it is always more presentable than on WhatsApp or email. It will definitely bounce back.”

He argues that although paper requirements per machine may decline due to eReceipts and digital records, the expanding base of ATMs and POS installations across India will offset it. “Paper requirement per machine might be less, but overall requirement would not reduce because the number of machines would be much higher,” he explains.

Quality parameters

According to him, in transactional printing, precision and consistency outweigh decorative print considerations. He notes that the most critical quality parameter is the sensor mark ink. “The most important quality parameter is the printing ink that we use, and that is the most expensive one,” he says. The black sensor mark printed on ATM and POS rolls ensures proper machine detection and alignment during transactions.

Equally crucial is slitting accuracy. “A roll is being precisely cut. If there is any issue in the cutting, printing or the black mark, the roll would not function properly,” Goel emphasizes. Precise slitting and controlled printing processes form the backbone of KDS’ quality assurance systems.

Scale, exports, and expansion

At present operating two paper roll units and a wire manufacturing facility in Greater Noida, KDS is in an expansion mode. The company plans to significantly scale its workforce and dealership network over the next two years, alongside strengthening direct business relationships.

On exports, Goel says the company has been serving Asian markets and working through dealers in other regions. Going forward, it intends to go for more direct import-export operations. “India will always play a major role in exports,” he says, citing the country’s manufacturing strength.

Beyond paper rolls and wires, KDS Group has diversified into food carts and handicraft trading. The group operates high-end food carts in select cities and plans an ambitious expansion in this space, along with establishing handicraft retail outlets nationwide. However, manufacturing remains central to its long-term strategy.