Konica Minolta has introduced a new variant of its KM1024i printhead, the KM1024i-SHE-HM-LV, which has been designed to be highly resistant to solvents.

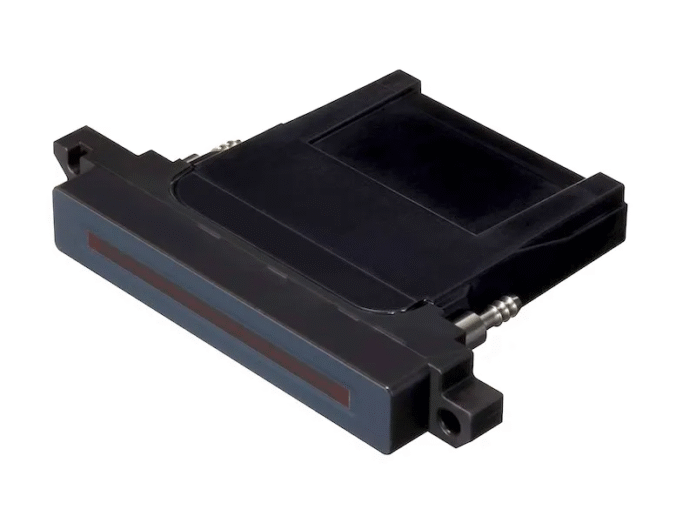

Konica Minolta has had considerable success with the KM1024i series, having developed a number of different variants to target different applications from graphics production through to industrial uses. The different models all use the same structure, with the same external size and electrical specifications.

This particular variant is primarily aimed at the manufacturing of displays, semiconductors, and other electronic products that might use fluids that contain solvents, which can damage some of the elements within a printhead. So Konica Minolta will have replaced some of the components within the new head to allow it to cope with those display materials that contain solvents. It’s also said to be suitable for organic semiconductor materials, next-generation solar cell fluids, and metal nanoparticle inks.

It has a built-in heater and can handle fluids with 3–5 mPa.s of viscosity. As such, it can also be used to form a perovskite layer, which uses low-viscosity materials. For those applications that need higher viscosity fluids, Konica Minolta also offers the KM1024iSHE-HM, which also has resistance to solvents but can handle fluids in the range of 7–12 mPa.s viscosity.

Kenichi Okubo, corporate vice president and general manager for Konica Minolta’s IJ Component Business Unit, commented, “Inkjet technology contributes to efficient manufacturing and so is in high demand from customers in various industries for their applications. The newly-launched KM1024iSHE-HM-LV expands applications to domains where it was difficult to apply inkjet printhead technology, including advanced fields such as perovskite solar cells.”

As with all heads in the 1024i-series, they have 1024 nozzles on a 72mm print width, giving them 360npi resolution. They offer eight greyscale levels. Both these heads are suitable for both UV and solvent inks. The SHE-HM head has a jetting frequency of 56kHz and a drop size of 6pl, while the new SHE-HM-LV model has a 44 kHz jetting frequency and a 7.5pl drop size.

You can find further details from konicaminolta.com or from Industrial InkJet, which offers sales and support for Konica Minolta’s printheads outside of Asia.