‘Impossible is nothing,’ a commercial slogan popularized by sportswear brand Adidas, is what Anand Chawla, the third-generation director of Kundli-based Anand Diaries, believes in. The manufacturer of boutique stationery has built a reputation in the diaries segment, both nationally and internationally.

Started as a stationery shop, Anand Stationery Bhandar, in Old Delhi’s Sadar Bazaar by his grandfather JRD Chawla in 1956, the 200 retail space has expanded to a 100,000 square feet office-cum-production facility in Sonepat. Apart from the 6-storey structure in the in the Kundli Industrial Area in Sonepat, there is the head office in Delhi’s Nariana.

Anand Diaries recently installed a Komori Lithrone G37 4-color offset press to add to its eight refurbished Heidelberg single and double-color presses. In the prepress and postpress departments, the boutique operation has five Heidelberg Stahl folders, three Aster sewing machines, two Siglock backlining and end sheet pasting machines, a 3-knife trimmer from Perfecta, six Polar cutting machines, a CtP from Kodak, DA2 70 and DAS case making machines from Kolbus, along with two casing-in lines, also from Kolbus. It has two sets of edge foiling and edge guilding machines from Chinese manufacturers that gild up to 3,000 diaries every day.

Chawla said he was impressed the moment he saw a brand new Komori in production at a printer where he used to outsource work. “Komori machines not only provide value for money but also have a robust output. I wanted to get a new Komori for Anand Diaries ever since I witnessed it’s output quality and production a few years back.”

Diary exports and inspired in-house design

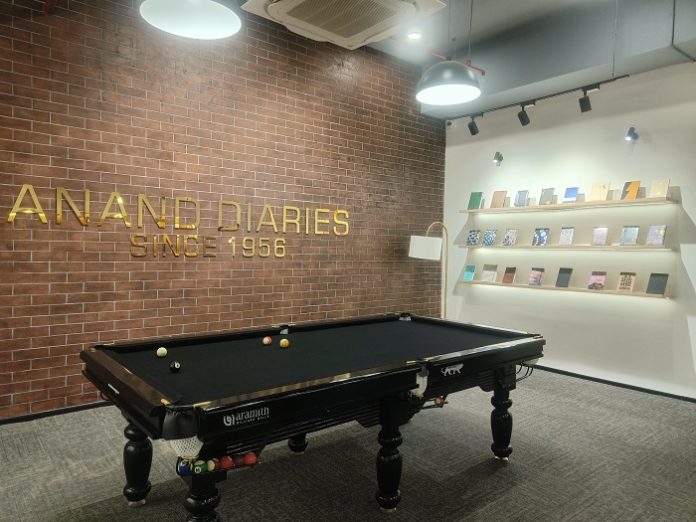

Anand Diaries has an elegant experience center at the Kundli factory replete with a snooker table and lounge area. This is where most interactions and ideation happen with existing and prospective customers, along with brainstorming sessions on new SKUs with the in-house design and creative teams.

The imaculate and aesthetically designed experience center allows visitors to handle and examine the unique products Anand Diaries supplies across India and 20 countries globally, including the UK, the US, Poland, Greece, the Czech Republic and Australia.

Chawla says the company began producing diaries and notebooks when his father SS Chawla joined the business in 1985. It had a 20,000 square feet production facility in Delhi’s Nariana Industrial Area from 1996 to 2014.

Changing its name to Anand Diaries in 2006, operations shifted to Kundli in 2014 with four small factories within walking distance of each other – altogether 70,000 square feet. To overcome the constraits of having four spaces, Chawla built the present plant on Niftem Road in the Kundli Industral area a few years ago.

Anand Diaries was already well known when he joined the business in 2006, fresh out of school, Chawla said, adding he did his graduation and MBA while working for the family business. Though the stationery manufacturer had reached every corner of India, Chawla used his marketing education to carve a place for the homegrown brand in the export market.

Today, Anand Diaries provides personalized stationery products and SKUs. “Once a particular product is selected for a specific brand or dealer, it is put out in the market for other buyers. We have 40-50 different SKUs for each of our 30 international customers, which makes it 1,500 SKUs for exports alone,” Chawla explained.

The company also produces white labeling for major stationery brands in India. While international clients are not keen to change their SKUs, more creative inputs are required to stay ahead of the game in the competitive Indian stationery market, he said, adding his brand is the only diary manufacturer in India that does not outsource the production of diary covers.

“Except for the raw materials, every step of the production process, from paper cutting to foiling to packaging, is done in-house. International customers often say our quality is better than Chinese stationery manufacturers and suppliers. We make it a point to decline some orders in orders to be able to maintain the quality of the orders we have accepted.” he said.

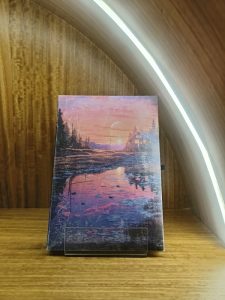

No original leather is used in its diaries and notebooks, he said, adding its faux leather or PVC (vinyl-coated paper) diaries are in high demand. The firm also uses PU and PLC-coated papers and paper-backed cloth for their sleek cover. Paper is mostly procured from Indian mills, including JK Paper and Andhra Paper Mills.

According to Chawla, inspiration for the diary covers can come from anywhere – discussions with customers, brainstorming, mood boards, the internet, and nature. “You just have to keep your eyes and mind open for fresh and innovative designs,” he said.