Materialise has released the latest version of its Magics software for the additive manufacturing market. The Magics 2025 release is said to make it possible to print parts that were previously beyond 3D printing.

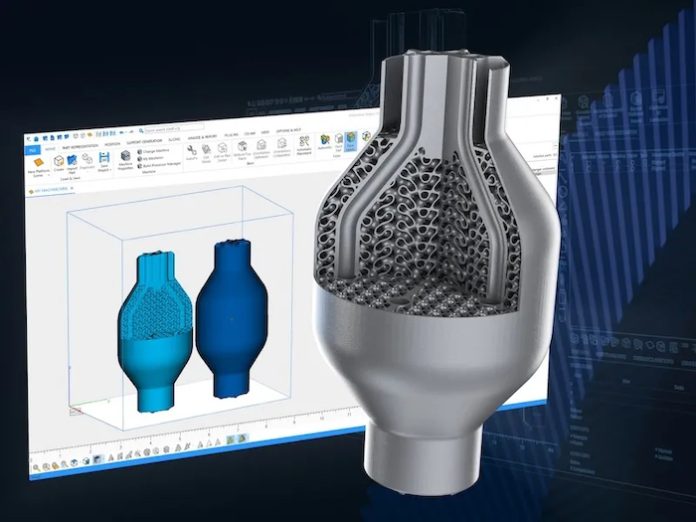

This claim is based upon a new ability for seamless processing of nTop implicit geometries without the need for mesh conversion in order to reduce the preparation time for complex parts. Thus nTop is an American software company that develops design software specifically for creating parts that will only be produced using additive manufacturing.

This fits with the Design For Additive Manufacturing movement, or DfAM, which differs from the more common approach of using CAD design to create parts that can be produced by both conventional and digital manufacturing. The DfAM approach allows designers to take advantage of the specific characteristics of additive manufacturing, such as latticing to create lightweight parts without sacrificing strength.

nTop engine

The nTop engine is based on computational design, which allows users to iterate rapidly through different variations, and to assess quickly how any changes will affect the final performance. The downside is that this requires substantial data and memory requirements. But now Materialise has improved the slicing capabilities of its new build processors to work with these designs. The build processor is essentially RIP’ing those designs to create the print instructions for a specific 3D printer.

Materialise and nTop set up an Early Access Program in 2024 to persuade users to try this technology. One of the participating companies was DMG Mori Technium Europe, which specialises in precision machining and additive manufacturing. Martin Blanke, a Project engineer with this company, explained, “Before joining the Materialise and nTop Early Access Program, meshing complex geometries consumed days of work. Now, with the new integration into Magics, it takes seconds. This integration hasn’t just streamlined our workflow – it fundamentally enhances our ability to design for additive manufacturing. Collaborations like this are exactly what our industry needs to overcome technical barriers and push additive manufacturing toward its full potential.”

BREP processing

Besides this, Magics 2025 also features extended BREP processing, which refers to Boundary REPresentation as used to define the volume of a 3D part. Here, Magics aims to help users work with native CAD geometry, by offering higher part quality, faster performance, and a reduced need for manual fixes. It’s suitable for CNC workflows as well as SLS, MJF, and Metal LPBF users. It supports advanced functionalities such as measurements, wall thickness analysis, nesting, and STEP file export for integration into CAM or CAD software.

Materialise has also sought to reduce costs associated with additive manufacturing, particularly around post-print finishing which can account for up to 60% of total costs. The latest Magics brings further optimizations for build preparation workflows and support generation, reducing material use and post-processing requirements while maintaining high-quality output.

Amongst the new features is ‘Replace Part & Transfer Support’ – which is used for series production and prototyping, and can reduce repetitive work, human error, and lead times. There is also ‘Self-Supporting Shell & Honeycomb’ – which minimizes the supports used in complex areas through self-supporting volumes, which reduces the post-printing processing.

The new release also includes several functional updates to simplify the user experience and to optimize rendering and memory usage for more efficient workflows. This includes up to 40% less video memory usage for marked mesh parts.

Enabling the next generation of additive manufacturing

In addition, Materialise has partnered with two other companies, Raplas and One Click Metal, to integrate the Materialise build processor into their systems. Bryan Crutchfield, vice president and general manager of Materialise North America, explained, “Materialise’s strategy is to enable the next generation of additive manufacturing by combining advanced software with diverse hardware platforms. Collaborations with Raplas and One Click Metal and the launch of the 2025 Magics release reflect our commitment to supporting the full spectrum of AM production. These solutions empower customers to save time, reduce risks, and lower costs, supporting successful AM builds from start to finish.”

One Click Metal has integrated the Materialise Build Processor into its ecosystem to give users improved control over their production processes and to streamline operations as it seeks further growth in the mid-market 3D printing sector.

Raplas focusses on resin-based additive manufacturing using the SLA or Stereolithography approach. Richard Wooldridge, CEO of Raplas, commented, “By combining Raplas’ tailor-made SLA 3D printing technology with Materialise’s advanced Build Processor, we are addressing inefficiencies of legacy systems. This partnership has already demonstrated remarkable results, including a 30-40% increase in printing speed, enhanced part quality, and minimum post-processing requirements.”

Udo Eberlein, vice president of software at Materialise, noted, “We are listening closely to the demands of the market and evolving our software portfolio into an integrated range of solutions that work together with other manufacturing tools. By addressing challenges such as cost, scalability, and precision, we are laying the foundation for seamless workflows that connect additive manufacturing to broader production ecosystems.”

Materialise mainly works in the aerospace, healthcare, and automotive, and as well as the software it also offers an extensive portfolio of 3D printing hardware. You can find further details on this from materialise.com.

First published in the Printing and Manufacturing Journal on 28th April 2025. Republished by permission.