The biennial Hunkeler Innovation Days is a curious kind of trade show. In some ways, it’s not really a trade show, since it hasn’t moved far from its roots as a corporate sales event for Hunkeler to reach out to its customers. But Hunkeler has truly embraced other vendors, including some potential rivals, and their customers, and this in turn has attracted the major press vendors, many of whom have traditionally used the event to launch their latest lines.

So when Muller Martini acquired Hunkeler in December 2023, many people worried that this would spell the end of this unique event. Fortunately, Muller Martini recognized the value of the HID event and left it in the hands of Hunkeler to organize.

There have been some changes at this year’s outing. The most noticeable is that an event that’s billed as being centered around continuous feed printing and finishing featured a great many sheetfed solutions.

Hunkeler’s CEO Daniel Erni explained, “In the past, some print vendors did bring smaller sheet processes but there was no focus on sheetfed at all because Hunkeler was traditionally not in the sheetfed business. But about five to six years ago we realized that especially with the new bigger and faster sheetfed presses, this would play a major role in the future. So we started looking at ways to engineer industrial sheetfed equipment. We are not going to build smaller sheetfed options. We are not going to compete with others in the smaller area because we are focussed on the industrial part of that industry.”

He continued, “So we wanted to bring the technology closer together from an operator’s standpoint. And over the years, the way we operate the sheetfed and rollfed equipment has become more similar so that it is easier for operators. As we are looking to our partners, the big printer OEMs, we feel that they are up for that. It takes a lot of time to develop this, but it’s turned out quite good now.”

New solutions

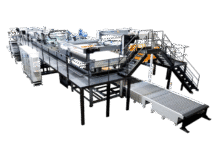

Naturally, every stand at the event featured some of Hunkeler’s distinctive white units with their transparent blue lids and Hunkeler itself introduced a number of new modules. This included the Gen8 Evo roll-to-stack solution, which is made up of other modules, including the UW8 unwinder, CS8 cutter, SE8 separator and LS8-30 long stacker, which can applications from 4x6ins postcards through to B2 posters.

The Evo version is essentially a more productive version of the existing Gen8 line. Dieter Altenbach, chief technology officer for Hunkeler. explains that the software has been upgraded, adding, “The machines are ergonomic and intuitive for fast set-ups and the operator is guided logically and supported. With the new panel, the operator can see all the relevant information.”

Stephan Estermann, Hunkeler’s chief operating officer, described the existing Starbook Ploughfolder, which forms pages into book blocks, as Hunkeler’s flagship, so it was not surprising that Hunkeler would introduce a variation for the cut sheet market. This included a Pallet Feeder linked to a SF8 Sheetfolder, followed by a Starbook module to create the Starbook Sheetfolder solution. This supports three types of production, allowing sheets to be turned and folded, cut in half and folded, or fed straight into the folding process.

The Sheetfolder, which was first shown at last year’s Drupa, has now gained a new multicut function to handle 8-up B2 sheets. It’s fully automated, changing formats on the fly to enable short runs even down to a single book. The SF8 also has a new perforation dust extraction system to reduce the buildup of dust and dirt from the perforation wheel, which should cut the maintenance time. For the show, automated pallet robots loaded the pallets into the feeder for a fully connected, streamlined production line.

Hunkeler also showed off a new DocuTrim B2+, which is also available in the B3+ format, and features a new sheet cutter. It’s designed to offer multiple finishing steps for single sheets in an automated line to minimize operator intervention. It offers edge trimming, center cuts, gutter cuts, and a variety of perforation patterns, all of which can be done both lengthwise and crosswise, and can be used for transactional and direct mail applications. It takes sheets up to 520 x 750mm and from 60 to 250 gsm, and can handle up to 11,500 sph. It will produce finished products from A3 through to A6. This was demonstrated in a near-line set-up with a pile feeder producing an 8-up postcard application on 250 gsm glossy paper.

Changing markets

During Hunkeler’s press conference, Erni claimed, “We invest 15%of revenues back into R&D to be state of the art.” He added: “We are the market leader for digital print finishing products with over 7000 installations.” However, the market itself is in flux. Nearly half of these installations (46%) are in publishing, with a quarter (2%) in transactional, followed by direct mail at 16% and commercial printing at 14%.

The noticeable emphasis on sheetfed solutions suggests that Hunkeler and its partners are expecting to see further growth in the commercial print market, where cut sheet presses are favoured due to the flexibility in substrate choice.

At the same time, most press vendors see packaging as their main opportunity for growth. Erni noted, “Of course, packaging is of interest to us and we have been looking at that market for many years now. But if we make the step into packaging then it has to be well-founded, technically speaking. With the existing machines, we are in a grey zone. We do have some installations. There’s a folding machine that folds baking paper. But don’t expect that Hunkeler will be bringing out a specific packaging machine in the next couple of years. We are still focusing on paper printing.”

Hunkeler hosted around 6,500 visitors over the four days of the event. Erni broke down the visitor numbers by region, noting that the UK and Italy represented 8%, with France at 6%, while Germany dominated with 26% of visitors. He added that the US accounted for 10%, saying, “And this is the most important market as that’s where the most innovation happens because they have the highest circulations.”

He went on to say, “I think the US printing market, just down to the size, is moving more, especially in the changeover from offset to digital printing. The European market is smaller and more hesitant, which might have more to do with the economic situation.”

Naturally, I asked if he was concerned about the threat of a US trade war. He replied: “Because most manufacturers in the print finishing sector are not in the US, this is more likely to increase the prices for the US customers and with that, we do have a risk that the whole market will slow down.”

He added, “We do have to talk about moving manufacturing to the US, and we can see that manufacturing in the US now is doable. However, we would have to realize that even if we can do that then we would have a price increase because we can’t just manufacture in small numbers.”

Hunkeler 2025

Erni opened his company’s press conference by stating, “The motto of this HID is Connect – connect people, solutions and processes. I think this is very fitting for our digital printing industry. We are an industry of people so connecting people is very appropriate because, in the final analysis, people buy from people, and trust in people.” He went on to describe the show as a meeting point for people from all over the world, adding: “and I would say that we are meeting as one big family.”

Hunkeler itself is still based in the nearby town of Wikon in the Swiss canton of Luzern, where it first started in 1922. The company moved into digital printing in the 1980s and has been part of Muller Martini since December 2023. Erni says, “The merger between us is working very well. Many members of staff in the past worked for one or the other company so our two philosophies are very similar and we have connected well together.”

He confirmed that Muller Martini and Hunkeler would remain as separate entities, saying: “We are complementary to the Muller Martini portfolio so it makes sense for us to continue like that.” He continued: “We will use the Muller Martini coverage in other countries to distribute our products. We will try to come up with the best solution for each country to add value.”

He went on to say, “We will deal with our finishing partners as Hunkeler, that is Horizon, Tecnau and so on. We will collaborate with them and give them our products. We analyzed all the products and believe that they are all complementary so the product portfolio will remain and develop as these things do but there won’t be any changes now.

This year’s event did have a different feel to previous years, mainly because it was enlarged to occupy both main halls at the Luzern Messe, with the on-site catering moved out to a new, third hall. Erni told me: “I’m pleased with how the new layout works out. We have on the second day about 4500 people which is 2-300 more than two years ago. And back then it was just too packed so the new layout is more comfortable for people in the halls.”

Having more space has also allowed for the main booths based around the presses to expand. This has taken away some of the democratic feel to the show because some vendors appear to have more space than others. But it has also allowed vendors to demonstrate much longer lines and a broader range of applications. As Erni noted, “We want to show real-life machines. We do not want you to see pictures and projections. We want to show real-life solutions and every partner has something new to show.”

I’ve already covered Screen’s new TPJ 520NX AD. For the next part of this report, I’ll look at some of the other presses that were shown in Luzern. When the series is complete you’ll be able to find all the parts with the hashtag #HID2025. In the meantime, you can find further details on Hunkeler’s own post-press solutions from hunkeler.ch.