On 1 September 2020, Quantum Design, owner of the KTI product line of automatic splicers and turret rewinders, announced its agreement with Hunkeler, a leader in digital print finishing solutions making it the exclusive supplier of automatic splicing and rewinding equipment for Hunkeler. The partnership results from many months of hard work collaborating on a custom automatic splicing machine, the Hunkeler RS8 model, and an automatic turret rewinder, the Hunkeler TR8 model. Hunkeler is already selling these new models as part of a complete inline finishing system for the digital printing industry.

The technology central to this collaboration is a game-changer for digital printing. Hunkeler will offer the first inline finishing system with non-stop end to end processing in the industry. Hunkeler displayed the full solution at its in-house event, Innovationdays 2019, and had plans to showcase the equipment at drupa 2020 before the event’s postponement. The initial launch of these machines in 2019 was very successful. Over a dozen installations were completed and delivered to the United States, Germany, Italy, and the UK in the first year.

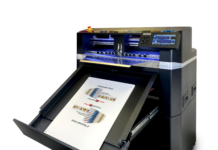

The RS8 is a shaftless automatic butt splicer with two shaftless roll positions that feed a continuous supply of material into the press. At the same time, the integrated storage festoon eliminates the need to stop for changing rolls. In-register splicing capabilities are available for running pre-printed material, which can dramatically reduce waste in the press when re-registering.

The TR8 automatic turret rewinder is also designed with two shafted roll positions to continuously rewind rolls directly from the press — eliminating the need to stop the press to remove rolls and offering greater throughput. The integrated festoon takes up material from the press while the web is brought to a controlled stop for cutting and transferring to a new core.

Both machines feature touch screen PLC Controls, and the quality construction for which KTI equipment is often recognized aligns with Hunkeler’s own equipment durability. Hunkeler and Quantum are currently in the design stages of a third model to be released and sold as part of Hunkeler’s finishing line in 2021.

“Hunkeler has a long-standing reputation as being an industry driver for new technology and innovation,” says Derek Wheeler, V.P. of Sales at Quantum Design, “We are excited to create this partnership with Hunkeler to bring continuous process equipment to the digital marketplace. We are excited to see where future collaborations will take both companies.”

“Hunkeler continuously expands its portfolio with automation modules and features with our valued partners for the Digital Print Finishing Segment of the Graphic Arts Industry. With its KTI product line, Quantum Design brings a tremendous amount of experience and technology into the partnership. However, automation is only the first step in the process to connect, integrate and create an end to end workflow for automated solutions from start to finish,” says Hans Gut, VP of Marketing & Partnering, Hunkeler.