In the five years since Langley Holdings took over Manroland Sheetfed, it has been able to create a sustainable company by selling 500 multicolor presses― many of them highly configured for advanced coating and foiling applications. The company is sustainable and profitable at a production level of selling just 100 machines a year although it has the capacity and momentum now to sell twice as much, or at least to double the value of its sales.

In addition, within these five years it has created a new press to eventually replace its well-known 700 series that was long a benchmark for monocarton production with what it calls the 700 Evolution. Apparently designed from the ground up with a sleek futuristic look, the newgeneration Evolution incorporates several technological developments and enhancements, aimed at printers looking to add the most value to the highest quality of print.

With this goal of high levels of efficiency, productivity, operation and quality, the newly designed central console replaces buttons with state-ofthe-art touchscreen panels. The panels give detailed graphical information in a user-friendly interface offering enhanced operation, flexibility and comfort, with options for left-handed and right-handed operation as well as customization for different operator body heights.

New Evolution feeder and sheet movement

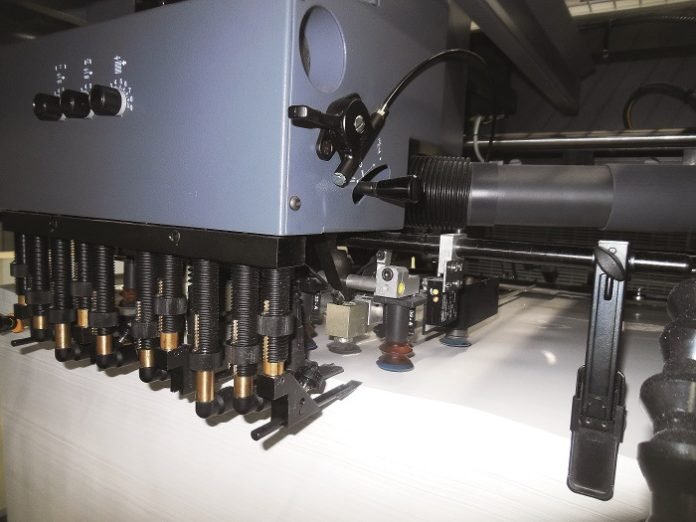

The new feeder pile transport brings appreciable productivity benefits with smooth upward motion of the pilecarrying plate and highly improved sheet travel from the feeder to delivery. This leads to fewer interruptions, less start-up waste and reduced walking distances to the feeder.

Solid fixing of the suction head reduces vibration and wear while ensuring safer sheet separation and higher average printing speeds. The newly developed suction belt sheet brake technology offers higher printing speeds combined with improved sheet alignment and tail edge stabilization.

Improved feeding is generally one of most neglected, yet crucial, ways of improving quality on an offset press since the entire inking system loses balance either when sheets are misaligned or arrive late or when the machine has to be stopped for resetting the feeder or even changing the pile. The new feeder even improves the shape of the pile in the delivery, all of which help increase productivity while improving print quality and saving on production costs.

Other new features include completely redesigned cylinder-roller bearings with separate bearings for radial and axial rotation for better absorption of vibrations with fewer doubling effects that can also extend bearing life as well as prevent deterioration of print quality. The new dampening system is also more solid with fewer roller vibrations. The new press design is a much greener machine with a 3-phase AC motor that does not use carbon brushes or wearing parts while combining high power output with much lower energy consumption.