Tosho Printing, a subsidiary of the global Toppan Group, has installed a highly automated 4- color and a 5-color high-end KBA Rapida 106 with LED-UV curing technology. The two new KBA Rapidas are equipped with a camera system for monitoring sheet travel, DriveTronic SPC dedicated drives at the plate cylinders, CleanTronic Impact combined blanket, impression cylinder and roller washing units, Emission Extraction System (EES), ErgoTronic ACR auto-register, QualiTronic ColorControl for quality control and inspection, optimum control strip height for improved paper format utilization, DataMatrixSelect and the LogoTronic Professional production management system.

Short lead times

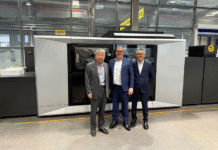

The management of Tosho Printing knew that their new Rapidas would produce more in an hour than their other machines and just one month after installation the two presses met the company’s ambitious targets. Even Tosho’s executives, who would have preferred to invest in Japanese technology, now trust in KBA presses from Germany. Despite high press speeds of 18,000 sph, the press operators can relax during production due to the high level of automation. The sheets that are cured with LEDUV can be sent straight to postpress reducing lead times, minimizing short-term storage requirements and enhancing overall productivity.

Tetsuo Ouchi, corporate officer – production control at Tosho Printing, says, “Japanese press manufacturers will have to work even harder. We hope that they will also develop the solutions already offered by KBA.” Nevertheless, he expects significantly more than the contractually agreed delivery and efficient service from KBA. “It’s all about working together as partners, even when it comes to developing new print products.” The company recently tested FlyingJobChange. It permits the even more efficient production of 1/1- color Mangas on a 4-color perfector. While units 1 and 3 are printing, units 2 and 4 are set up or vice versa.

Newspapers and commercials

Founded in 1911, Tosho Printing now operates 30 sheetfed offset presses and other newspaper and commercial presses at five sites. Yomiuri, Japan’s largest daily, and others are produced at the firm’s three newspaper operations. The other two specialize in commercial products, books and magazines. The same is true of the plant in Kawagoe-shi in Tokyo that operates the two new Rapidas.