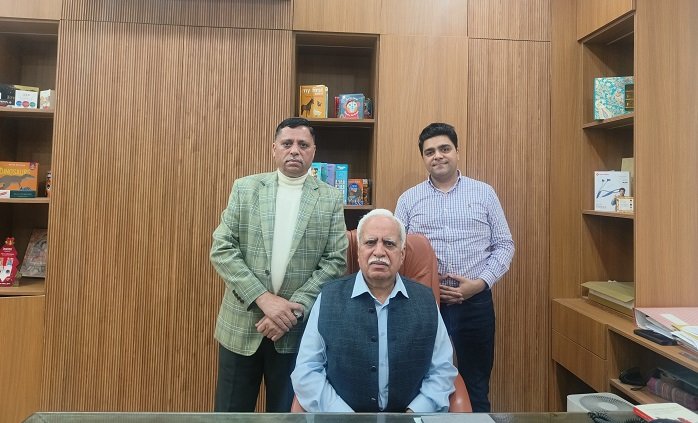

Kundli-based Paras Offset is a commercial printing and packaging business with roots in Delhi. Established in 1967 in Old Delhi by Munilal Jain, Paras Offset is currently run by his sons Praveen and Vinay, and grandson Aditya from a 1,25,000-square-foot plant in the Kundli Industrial Area in Sonepat.

Paras Offset specializes in children’s books — board, gilded, fabric, and sensory/tactile books, learning kits, and activity books with integrated interactive audio and video components. It produces 8,000 board books daily for domestic publishers across the country and for exports, and has an overall daily production capacity of 25,000 perfect-bound books.

Apart from children’s books, the company manufactures board-based games, toys, and jigsaw puzzles, along with academic and coffee table books in paperback, hardcover, and centre-stitched formats.

Commercial print products include calendars, magazines, catalogs, brochures, tattoos, stickers, and greeting and wedding cards. Alongside these, point-of-sale (POS), marketing and promotional materials, and tarot cards are produced, along with garment tags and hangers.

The packaging vertical produces monocartons, heat-seal blister packs, rigid boxes, sweet boxes, and labels. According to Aditya Jain, the founder’s grandson, Paras Offset converts 500–600 tons of paper and paperboard each month.

Print capacity enhanced

Having recently added a new Komori GL-37 to its pressroom, Jain said the company was earlier a satisfied Heidelberg customer. It invested in a brand-new Komori 4-color GL-37 with KP-Connect software after learning about these features and the cost-efficiency of Komori machines from fellow printers.

As a traditional user of refurbished Heidelberg presses, Paras Offset’s pressroom contains a 10-color Heidelberg perfector, two Heidelberg 6-color CD-102 presses, and two Heidelberg 4-color presses. It also runs a K&B 2-color press.

Paras Offset’s prepress section runs a Kodak Trendsetter 800 CtP with automatic stacking. Jain says the company uses only double-layer thermal offset plates, enabling the reproduction of fine 1% dots for high-end work. Epson printers are used for proofing. All the presses are color-calibrated to the ISO 12647 standard for enabling quality, consistency, and reduced waste, according to Jain.

Certain substrates are printed at 220 lpi to achieve the highest print quality. A pair of in-house designers also provide photography for packaging design and use a Chinese sample maker for prototypes and mock-ups.

A complete bindery for perfect binding and hardcover books operates two Bindwel BW@2500 6-clamp perfect binders, six Stahl folders, a Chinese HPM cutting machine, in addition to multiple cutting machines from Perfecta-Seypa and Polar. A fully automatic Sakurai Maestro 102 screen printing machine sits alongside an automatic lamination machine from Zhongke.

Packaging vertical

The company produces window-patched, metallized, and non-metallized monocartons for the F&B, electronics, liquor, and pharma packaging segments. Jain said they have consciously stayed away from specializing in a particular segment, which has given them the expertise to service multiple segments. Most clients are from the Delhi-NCR and from the nearby states of Punjab, Haryana, and UP.

An ERP system developed by the company helps it track and monitor print and packaging work, routine tasks such as daily machine scheduling, efficiency, and breakdowns. Food industry clients are assisted in placing and tracking their orders through an online management system.

For finishing and converting cartons, Paras Offset has a Bobst SP 102 die-cutter and an Eterna folder-gluer capable of 4- and 6-corner boxes. Additionally, there are six manual die-cutting machines, a Chinese flute laminator, two Chinese rigid box lines, and a Creofoil digital foiler, along with ancillary equipment such as grooving and pasting machines.

Jain says the company is focused on value-added printing and co-creating new products with customers. When customers approach it with a challenge, the in-house design team is able to provide creative solutions. Forthcoming plans include an office in the US for exports that was shut down to be reopened in anticipation of demand growth for both academic and children’s books and packaging.