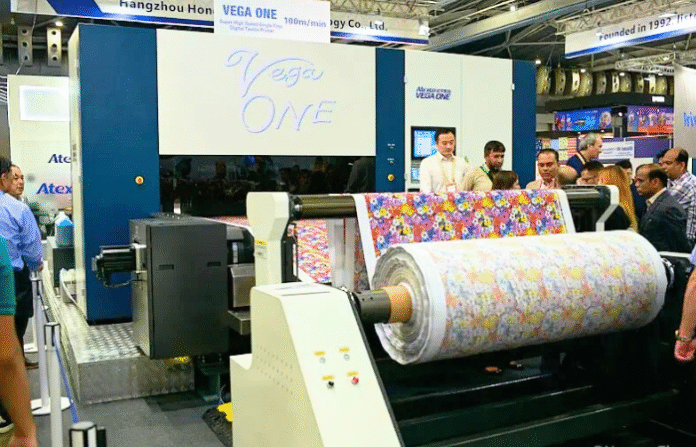

Atexco brought two new textile printers to the ITMA Asia show in Singapore, including the Vega One Mini single-pass press and an updated version of the EcoPrint multi-pass machine.

As the name suggests, the Vega One Mini is a slimmed-down version of Atexco’s large single-pass press. Yiyi Zhang of Atexco told this writer, “Everybody thinks that single pass is for mass production. The width is 1.3 m, and we only have 48 printheads. Before this, the smallest single pass was 192 heads.” Actually, the Vega One was already available in a 1.3 m width, as well as 1.7 m and 2 m, but the model shown in Singapore had a significantly smaller print unit.

She said that it had had a good reception at the show, noting, “Many people like this because it’s smaller and obviously cheaper, but it’s still single pass. So we can cater to more customers. If the Vega One is too big or too expensive, then they can buy this. They can start with the smaller one and then maybe one day buy a bigger one.”

The Mini will take reactive, disperse and pigment inks, meaning that it can cover all the main fabrics that anyone would want to put through a single pass press. It only has room for four colors – CMYK – but most customers will see this as a benefit. That’s because the main reason most vendors develop single-pass presses is for the high volume of ink that these machines consume, so limiting it to four colours will also help keep the running costs under control.

That also means that each printbar consists of 12 printheads. The heads themselves are Kyocera EX 600 RC recirculating heads with 600dpi resolution. The press is capable of producing 100mpm. At the same time, Atexco will also upgrade the rest of the Vega One platform with the same printheads to raise the maximum speed for all the Vega One models from 80 mpm to 100 mpm.

As with other Vega One models, there’s a coating unit with an analogue roller built into the press, so the fabric roll goes from the unwinder, through the coating unit, then the printer and drying unit and onto the rewinder.

Atexco has already sold the first Vega One Mini to a customer in Pakistan, which will act as the beta site. This customer is already using Atexco printers and so is familiar with the processes and software. Atexco didn’t bring the dryer unit to Singapore, but customers will be able to choose between electric or gas and one will be installed at the customer’s site. Atexco anticipates completing beta testing in one month, which seems quite ambitious for a new machine, even though it’s essentially a slimmed-down version of an existing platform. Nonetheless, the Vega One Mini should be commercially available within one to two months from now.

Interestingly, Zhang says that Atexco is also planning a smaller version of the Mini with a width of 1.2 m, which will mean even fewer heads at just 44, further reducing the price.

Atexco EcoPrint

The second of these new printers is the EcoPrint, though this is an additional version to the existing EcoPrint. The EcoPrint is a 1.8 m wide multi-pass printer that’s been designed to run with pigment inks, so there shouldn’t be any need for the multiple washing and steaming cycles associated with other textile inks.

It uses Brother printheads, with Atexco trying to diversify its choice of printheads. Atexco did not want to say exactly which heads, but did say that Brother is very familiar with pigment ink so it is confident in the Brother heads for this printer. (It’s worth noting that Atexco is also developing a second printer with Brother heads but with reactive inks, which appears to be a variation on the EcoPrint.) Both the original and new versions can be set up with either eight colours or two sets of four colors.

The original EcoPrint used 24 printheads, each with two channels, but this latest version is fitted with 32 heads, each with four channels. The heads in the EcoPrinter only produce 300 dpi native print resolution, though multiple passes will increase the print quality. The print quality coming off the machine on the stand in Singapore was very good, but this was running at six passes. Atexco expects most customers to use two to three passes, which should yield 300 m/hour. Not surprisingly, this is much faster than the original version, which ran at 160 m/hour for the same mode.

This new version of the EcoPrinter also gains Atexco’s proven Camera Point system, which uses a vision system to identify the positioning of the substrate and then adjusts the file to match. It’s a neat system that allows it to take into account factors such as the stretchiness of the fabric.

The EcoPrint is available to order now. You can find further details on Atexco’s textile printers from atexco.com.