Valmet will supply two OptiWin Drum two-drum base winders to Wuzhou Special Paper’s paper machine PM 21 in China. This new order follows the customer’s previous winder order, announced in July 2024. The target of this latest investment is to have high-technology winders that can meet the paper machine’s high capacity and quality objectives.

The order is included in Valmet’s orders received for the first quarter of 2025. The value of the order will not be disclosed.

Founded in 2008, Wuzhou Special Paper Group, located in Quzhou City, China, is mainly engaged in the R&D, production, and sales of special paper. The offering includes food wrapping paper, glassine paper, tracing paper, transfer printing paper, and special fine paper. The company is one of China’s largest manufacturers of glassine paper and tracing paper.

“We know Valmet’s OptiWin Drum two-drum base winder technology well and trust that this high-class winding technology can reach our capacity and quality targets. The collaboration between Valmet and Wuzhou has been good during the project, and we want to continue developing that partnership,” says Zhang Yanchen, deputy general manager, Wuzhou Special Paper.

“We were happy to help the customer find optimal winding solutions that fit the requirements of the multiple grades they produce and support the paper machine’s smooth transition to production with an efficient delivery schedule. This repeat order continues our long-term partnership with the customer and strengthens Valmet’s position as a trusted supplier of advanced finishing technologies,” says Esa Ananin, product sales manager, board and paper mills, paper business line, Valmet.

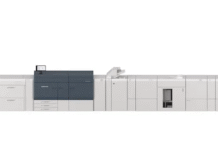

Delivery’s technical information

Valmet’s delivery includes two OptiWin Drum two-drum base winders with automatic functions such as set change with core and tail gluing and slitter positioning. A spare parts package and Valmet Industrial Internet connectivity solutions will also be delivered.

The winders will handle parent rolls with a width of 8,415 mm at a design speed of 3,000 m/min.