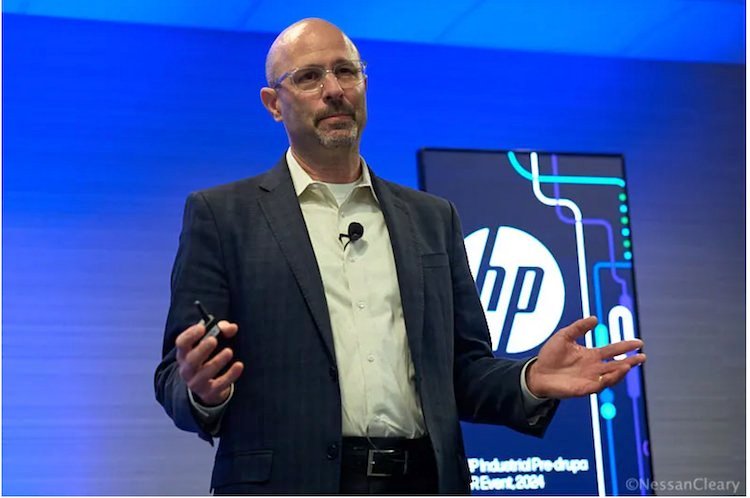

HP has announced two new inkjet PageWide Web presses, the 107 centimeter-wide T4250 HDR with a new recirculating printhead, and the monochrome T500M HD book printer, both of which are significant machines but for different reasons.

The T4250 HDR is targeted at the publishing, direct mail and commercial print markets. As such it can be seen as a follow-up to the T485 HD press and is said to be up to twice as productive. However, it has the same maximum speed of 244 meters per minute or 800 feet per minute so how can HP claim that it is more productive?

The answer is that it is faster for certain types of jobs. There are some jobs that cannot be run at the full rated speed of the T485 HD because those with higher ink coverage or thicker substrates take longer to dry due to the water content in the ink. So the key to the new press is a new printhead design that has allowed HP to reformulate the ink for faster drying of those jobs with higher ink coverage so that more of those jobs can be run at higher speeds.

The new HD RNA head is a thermal printhead, based on the existing HD head with its 2400 nozzles per inch but with a new ink recirculation system. The current HDNA heads have two separate ink channels so that they can be used for two different colours. The two channels mean that normally there would be two ink inlet connectors.

Rolando Martinez, HP’s head of worldwide product and solutions product management, explains, “With the recirculating head the two channels are connected. So instead of having two ink inlets we have one that goes in and one that goes out. So all we did was connect the chambers inside. We have the flexibility with the thermal inkjet to do these types of things.”

Yale Goldis, HP’s director of strategy for commercial products and solutions, elaborates, “In our HD printheads the ink goes into the chamber and then gets fired out of the nozzle, and there’s no connection back to the ink reservoir. In the recirculating head the ink can go into the chamber and out of the chamber and when it’s time for the ink to go out to the paper then the ink gets jetted through the orifice.”

The advantage of this is that the ink is constantly moving around. Without the recirculation, the ink is sitting in the chamber and can be exposed to the air through the open nozzle. Martinez says, “These nozzles that are exposed to the air, even if it’s just a few microseconds that’s not printing in that area, they might dry out because the ink is just sitting there. But now that it’s recirculating it allows us to put an ink that can dry faster because it’s all the time moving.”

He adds, “We still have to do some spitting occasionally but much less than before because you have less ink that is sitting there and exposed to the air.” (Spitting is the practice of forcing small amounts of ink through the nozzles to keep them clear which is common for most inkjet systems.)

Since the ink is constantly moving, HP has been able to reformulate the ink. Typically most water-based inkjet inks include a number of agents, besides the water and the pigment, to improve the overall system performance. The existing B60 ink that is used in the T485 includes an anticoagulant to limit the risk of the ink drying out in the head, which would then clog the nozzles. Of course, the problem is that we want the ink to be as wet as possible when jetting and yet also as dry as possible once it’s hit the paper. Inevitably this anticoagulant makes it harder to dry the ink, particularly for high coverage jobs.

Martinez explains, “Before we had to add components that slowed down the coagulation of the ink, the drying of the ink. We could not remove those components before because the ink was sitting there. But we have been able to remove those anticoagulation agents so now the ink can dry a little bit faster.”

Martinez says that HP’s tests show that some jobs can be run up to twice as fast as previously. “So those jobs – high coverage, thick substrates – which typically printers thought of as jobs for offset because they would have to slow down the high investment inkjet press, now those type of jobs can be moved to digital because it’s more productive than before.”

In addition, the HP web presses do allow for a very fine degree of control over the running speed, down to changes of just 1 mpm if needed, which allows operators to set the fastest optimum speed for the combination of job parameters and media in use.

As with the T485HD, the T4250HDR has ten printbars – two each for the CMYK inks plus the optimizer. The new B70 ink has also been updated with an offset magenta hue to address the commercial color space. The new recirculating heads are only used for the colors with those for the optimizer being the same HDNA heads as the T485 uses. The optimizer performs the same function of enabling printing on both uncoated and coated media. It will take rolls up to 1067mm wide and can handle standard offset coated paper, including glossy, silk and matte, from 40 to 350gsm

It’s worth noting that the HD RNA is not HP’s first recirculating thermal printhead. Back in 2018 the company introduced the R2000 latex flatbed large format printer, which included a white ink that also required a recirculating printhead. However, in that case the ink chambers from one row of nozzles were combined with those from another row, to allow the ink to recirculate. This halved the number of available nozzles. But the new HD RNA head retains all the 2400 nozzles per inch resolution and has the same perforce as the T485’s HDNA heads.

Recirculation should also benefit the maintenance of the heads, with Martinez adding, “We expect to have a higher printhead life expectancy. We are still in the early phases of evaluating and have just started a pilot test. Our internal testing shows that there is an extended life but we are evaluating in real life how much it is.”

Most of the performance figures for the T4250 remain similar to the T485HD, despite HP’s marketing statements, because they quote maximum speeds with lower ink coverage. So the press still runs at 244mpm and will still produce around 20,000 B1 duplex sheets per hour. The duty cycle has gone up to 173 million A4 full-color images per month. The real improvement is harder to quantify. The new press will only really benefit those customers that are running high ink coverage jobs, or regularly using thicker media, which should see a significant boost in productivity. However, HP is still trying to evaluate how much this will affect production in real terms.

Martinez says that there are customers in direct mail and marketing as well as general commercial print that will benefit, noting, “We are targeting that higher end, higher coverage type of work.” HP will continue to sell the T485 HD as the T4250 HDR will come at a higher cost and there will be some customers who won’t need it if they are more focussed on lower coverage jobs.

It will also be possible to upgrade some of the existing T485 machines to the new T4250 spec. However, the upgrade would depend on how old the existing press is. Martinez says, “We will evaluate depending on the generation as to what is required. Our intention is to offer upgrades but we have to evaluate what will be required of each generation and platform that the customers have to come up with an upgrade path if possible. Toward the end of the year we will have a better understanding of the upgrade path for older generations.”

Back to black

The second of these new presses is the T500M HD. This is a monochrome press aimed at the book publishing market, promising suitability for shorter run lengths, tighter turnaround times, and more frequent high-volume orders. It is essentially a wider version of the existing T490 HD, with the same writing system, including the HDNA printheads and A30 black ink, and the same 305mpm maximum speed.

What is new is the 138cm width, necessitating a new chassis from the usual 107cm/ 42ins width of the rest of the T400 series – hence the new T500 moniker. It will take rolls from 30.5 cm up to 152.4cm in weights from 10 to 150 gsm. It can handle standard uncoated offset media as well as inkjet optimised papers.

Martinez explains, “This press was designed with the book manufacturers in mind for black and white mono trade books that are produced for general audiences. We focussed on particular sizes – 15x23cm, A5 and 14x20cm – which cover about 75 percent of the book industry. With these page sizes on a smaller format you can only put six pages across the web but the book manufacturers told us that in order to put eight pages on a sheet, which is their typical signature, they need at least 1.3 meters width. And this is the typical size of offset presses such as Timsons.”

Of course, the main reason that book printers still use offset is to do with the economics around print runs. Goldis says that this varies from one customer to the next because it largely depends on the mix of equipment that they each have. He says that people continue to use long runs but that the run lengths are coming down. “There are still a lot of people who like to buy books, and this allows the flexibility to print in large-volume smaller-run lengths of books. And because this is now the same width as the analog process it’s more efficient for printing the large majority of mono trade book sizes.”

Goldis adds, “And the publishers want the same number of pages with no additional blank pages that you might get if you have a different size signature. But with the same signature size as analogue then you can take the same roll of paper and put it on your analogue press or on this digital press. The publisher sees the same number of pages, the same binding, so it all looks the same to them and it gives the choice to the book manufacturer as to how they can optimally produce the work for the publisher.”

HP has also worked with Magnum and Manroland to ensure that there are existing finishing options that can be used with this press. The idea is that the postpress units are integrated with the inkjet press into a single line. Goldis says that digital requires different finishing, “What comes out of the press is a completed book block when that finishing is attached so it saves all the labor and space from a traditional analog process”

Demand for traditional books returns as Kindle frenzy slows

Martinez points out that the book industry is enjoying a resurgence, saying, “The Kindle frenzy has slowed and the trends show that demand is coming back for the traditional trade books. And we see that also happening at Amazon. What initially killed the book – the Internet – is helping it come back again with these online communities for books where a book can become viral and suddenly there are short runs that need to be produced very fast. And with all the geopolitical challenges everyone wants to take risk out of the supply chain in order to manufacture closer to their customers.”

All this leads to the obvious question – will HP produce a color version on this new 1.4m chassis? Goldis says, “Right now we are talking about the mono press and this is a purpose built machine for mono trade books. Maybe in the future there will be more demand for those sizes of books in color but today the world is mono in those sizes. And we have the 4250 press for color.”

You can find further information from hp.com. The T4250 HDR press should be available at the end of 2025 with the T500 scheduled for 2026. Naturally there is no word on pricing though customers can place orders now.

First published in the Printing and Manufacturing Journal on 7th February 2025. Reprinted by permission www.nessancleary.co.uk. Note – Nessan Cleary will be covering the forthcoming Hunkeler InnovationDays for Indian Printer and Publisher and Packaging South Asia.