First of all go from competence to excellence in what you are currently doing if it is commercial printing. Pragati continues to demonstrate great belief in commercial printing and it is the first to say that it is a slow learner and that the learning curve is steep. Narendra Paruchuri is the first to admit that it has taken his company 17 years to achieve a mere 36% of its turnover in labels and packaging.

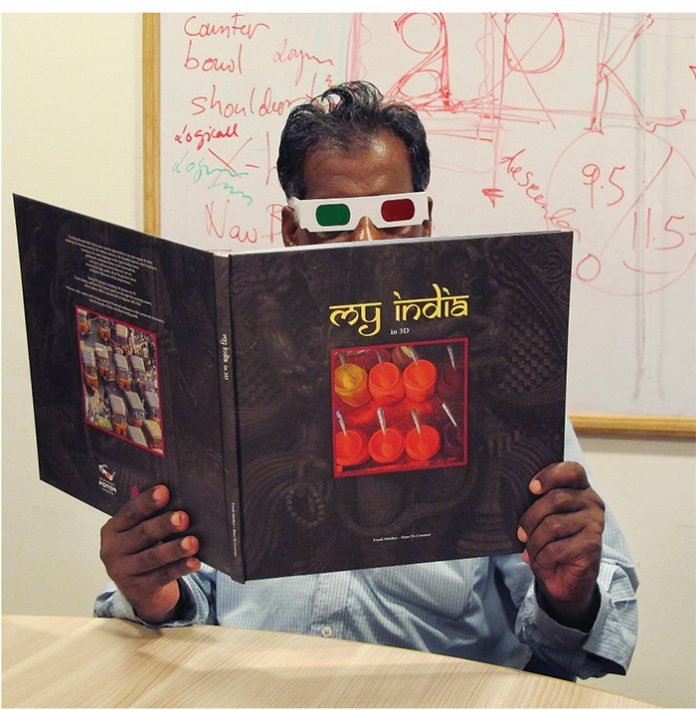

Narendra Paruchuri of Pragati

based in Hyderabad has been a frequent speaker at confer- ences and seminars and he has made it a point to be helpful to other printers when they want to understand a subject

- whether it is software, automation, training issues or business issues. Lead- ership of the Indian print industry has come not just from the company’s fo- cus on color reproduction quality or product finishing and global recogni- tion through awards, but from commu- nication to its clients and the industry at large — tech talk as well as the indus- try trends that it perceives.

Leadership has also come from the company’s organized effort to build a professional sales funnel with repre- sentation and offices in 11 Indian cities. Another key is the company’s character when it faces business deci- sions — be it training, equipment choice and specification, the induction of its next generation or its attitude to diversification.

Commercial still dominates turnover

Of Pragati’s total turnover, the over- whelming majority — 64%, still comes from commercial printing while the balance 36% consists of labels and packaging. It has taken the company 17 years to get where it is in packaging

- a winner of several Sappi, Asia Star and Worldstar awards and an active participant at packaging exhibitions where it shows its innovation capabili- ties to brand owners and packaging buyers.

Narendra Paruchuri explains that commercial printing and packaging printing are similar in one way and very

different in many ways. “Similar because they use a printing machine which can do both commercial and package print- ing and different in many ways, as all the other processes are specialized. Be it prepress or postpress, or knowledge about various papers, boards, corrugation, and the variety of pa- perboards, or the science of how packaging is structured to perform on high speed automated filling and sealing ma- chines — the subject of packaging is vast,” he says.

Moreover, he cautions against losing belief in commer- cial printing, “We feel that commercial printing will still grow, albeit at a slower pace compared to packaging. It might plateau and then perhaps decline. I am not sure about this as consumption levels of paper in India are still dismal and as our economy grows, printing will grow as an integral part of it. Packaging will no doubt grow at a reasonable rate. Our in- vestments and studies are also more in this area but the learning curve is steep and expensive. However, opportuni- ties are also there and as long as we hit the target 6 or 7 times out of 10 attempts, the average will be fine and we will emerge victorious.”

Pragati has always innovated and specialized as when it li- censed a special type of packaging that it pioneered in the country. Or when it experimented with Hexachrome and 7- color printing in the previous century. Its most recent invest- ment in 7-color presses to print an extended gamut of colors also comes from its targeting a specialty segment in com- mercial printing.

This latest innovation in commercial printing includes the use of new software and hardware for 7-color printing to produce (an extended gamut) including many Pantone shades very closely. To process and print a wide variety of per- mutations and color combinations would be a nightmare to copy or counterfeit. Additionally, the press need not be washed up to achieve so many true matching colors. A lot of time and money can be saved by not having to wash a million dollar press for 15 to 20 minutes to get the correct shade.

Specialize to succeed in packaging

Paruchuri has good advice for commercial printers looking at paperboard packaging, “Today when many commercial printers are saying that we will get into packaging as that field seems better and appears to promise surefire growth in the future — they can certainly do this, but they will have to go through a steep learning curve. They need to keep in mind too, that the simple multicolor printed cartons, which are printed, punched and pasted are at the bottom of the pyra- mid. Only price matters in this segment and this is not some- thing that printers aspiring to diversify would want to get into. Specialty segments are a must to stand out in a crowd and that is what gives the fillip to a business to go further.”

Paruchuri further explains, “Even if one wants just to learn about printing on paperboards for cartons, one needs to learn about grain direction, the way to efficiently populate multiple pieces on a single sheet, the printing, the various of- fline coatings and finishing from embossing to foils and many other embellishments, then the punching or diecut- ting and pasting — each of these is a subject by itself.”

Pragati obsessively learnt coating and UV coating and inks. This was one of its earliest routes to innovation and spe- cialization. This knowledge and understanding of what coat- ings can do together with their prepress requirements is one of biggest capabilities that the company brought to its pack- aging diversification. If you are getting the gist of this case

study you might be ready for the first and main lesson or rule

that emerges before diversification. Of course it’s also some- thing your mother may have told you when you were younger: ‘Before you do something else, why don’t you prop- erly learn to do what you can, with what you already have?’

Embellishments and postpress operations add a lot of value to the premium-ness or premium quality of the carton or label. This includes hot foil stamping, embossing, micro- embossing both for decoration and security, screen varnish- es, holographic UV varnishes, textured and matt UV var- nishes. These operations add to the grandeur of the pack that will stand out in a crowded market place.

The great importance of branding is now being recog- nized by even small manufacturers and they are willing to spend to establish their brand. And it all starts with the pack- aging. This is the first point of contact or sight for any prod- uct. Many a time this is the make or break point. This is an of- ten repeated thought but a very correct estimation. Paruchuri says, “The first time sale is due to what is on the pack and the repeat sales are because of what is in it. So not having a good packaging is detrimental to the brand. This is where we talk about Coke red, Pepsi blue or the Liril green. The brand comes to your mind as soon as you see it.”

Paruchuri concludes by saying, “Indian Printer and Pub- lisher recently editorialized that the printing volume has in- creased considerably in the past decade. But the numbers of machines have increased a lot more and this over capacity has resulted in cost cutting and unhealthy competition. I only hope that all our printer colleagues understand that it is the client who is going to benefit at our cost. The goal of business is to make money and we should do this. In order to do this we must also deliver a great product. Once we are clear about these two key pillars in our business, things

should go well.”