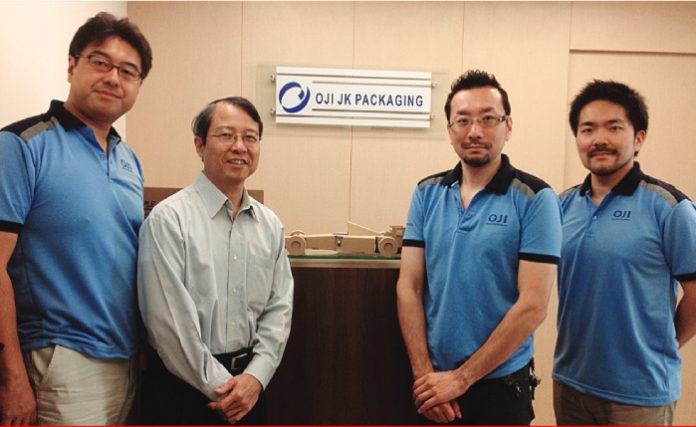

Oji Holdings Corporation, the fifth largest paper producer in the world and which generated around US$ 12.5 billion in revenues last financial year, commenced the trial run of its packaging unit for corrugated boxes and sheets in Neemrana in May 2014. Throughout its history spanning close to 140 years, the Oji Group has maintained its position as the leading company in Japan and produced 6.6 million tonnes of paper and paperboard in 2012. Oji has entered India by joining hands with JK Paper and Marubeni. After the stake acquisition in 2012, the company is renamed as Oji JK Packaging and holds 60% stake while the remaining 40% is split equally between Marubeni and JK Paper.

ji JK Packaging has set up its plant in Neemrana Industrial Park, Phase 3, Rajasthan with a share capital of `48 crore which is going toabsorbaninvestmentworth`150 crore. With a purpose-built building of 15,364.18 square metre on a land of 34,156 square metre, the company is expecting to reach a manufacturing capacity of 34,000 tonnes of packaging products per annum. “Weareplanning to increaseour production capacity gradually in phases insteadof delivering 34,000 tonnes inthe initial stage. Increasing theproductionin stages will help us produce the desired quality comfortably and profitably,” says Akio Hasebe, managing director, Oji JK Packaging.

JK Paper is India’s leading branded paper company and is present in all the high-growth segments in India, name- ly, office paper, coated paper and virgin fibre packaging boards. On the other hand, Marubeni is involved in the han- dling of products and provision of serv- ices in a broad range of sectors encom- passing importing and exporting, as well as transactions in the Japanese mar- ket, related to food materials, food products, textiles, materials, pulp and paper, chemicals, energy, metals and mineral resources, transportation ma- chinery, and includes offshore trading. The company’s activities also extend to power projects and infrastructure, plants and industrial machinery, fi- nance, logistics and information indus- try, and real estate development and construction. For its Neemrana plant, Oji JK is sourcing its paper from seven to eight major paper manufacturers in India and is not depending completely on JK Paper for its raw material supplies.

Inside Neemrana plant

The automatic plant in Neemrana in- corporates the latest available technolo- gy to produce high-quality packaging products required by consumer durables and electronics, auto components, FM- CG and food industries. The commer- cial operation of the plant is expected by July 2014. The plant is equipped with German-made BHS Steady Line SF-180 which can handle a width of 2,200 mm sheets. The machine has two single face corrugators — one for A and B flutes and another for A, B and C flutes, giving it flexibility to produce thick and heavy-du- ty double-wall boxes for high-load appli- cations. The plant is equipped with two presses, one capable of printing 1200 x 2700 mm 4-color sheets with a speed of 200 sheets a minute and the other capa- ble of printing 1600 x 3200 mm size 3- color sheets at a speed of 160 sheets a minute. Both the printing units are man- ufactured by Plus Energy Manufacturing Corporation, Taiwan. The Super Crest

2.7 folder gluer is from Oshitani, Japan with outside grooving and counter ejec- tor facility. Gluers and auto stitchers for the final finishing of the boxes are from China and Taiwan.

Oji’s market strategy

In India, Oji will provide both corru- gated boxes and sheets to the market. The company has tied up with several Japanese companies in Neemrana and its adjacent areas to provide them its packaging solutions. Setting up the Oji plant in Neemrana is a well-thought-out plan as the location where the plant has

been set up is a Japanese industrial zone where reputed Japanese companies like Daikin, Toyota Kirloskar, Panasonic, Unicharm and many more are present. Oji aims at tapping these companies for their products. “We already have a good relationship with these companies in Japan and are a major supplier to them,” says Hasebe. However, the com- pany is also getting help from Marubeni in terms of acquiring clients, although at a minuscule level. Oji has plans to reach out to the domestic clients too and the strategy to cater to fellow Japan- ese companies is, however, just the ini- tial platform to start with in the Indian market, which is mostly fragmented and dominated by unorganized segment op- erating manual or semi-automatic plants that lack scale and consistency in product quality. “We also ask our Japan- ese clients to introduce us to the local Indian companies and in this way we have been able to generate a good rela- tionship with the domestic companies who are now willing to buy our prod- ucts,” adds Hasebe.

“It will be easy for us to sell to the Japanese companies because we already understand their requirements very well, and getting the same high-quality products in India as in Japan will be a great advantage for them,” says Yosuke Fujiwara, director controller at Oji JK. “We are very much focused on improv- ing our quality and bringing it to the lev- els of our customer needs,” adds Fuji- wara.

Testing equipment

For quality control and delivering bet- ter products, Oji JK has implemented a complete set of testing equipment for checking the bursting and compression strength of brown boxes along with the crush resistance of the corrugation. They also have a high temperature lab- oratory oven to control the moisture of the paper and board and have a recy- cling plant for water which helps them minimize the water requirement of the plant. Oji also has a packaging design unit in Neemrana where they design custom-made boxes for its clients who need lightweight and high durability corrugation boxes to reduce the cost of logistics and warehousing.