Aakar Design-O-Print, a Delhibased print firm owned by Manjit Singh, is yet another story of a traditional commercial printer with sheetfed offset presses entering the lucrative packaging market. The company diversified into packaging in 2000 and is doing remarkably well in this segment. Today, Aakar not only prints magazines, brochures, posters and leaflets, but is also one of the leading producers of monocartons for the FMCG, food and pharma segments.

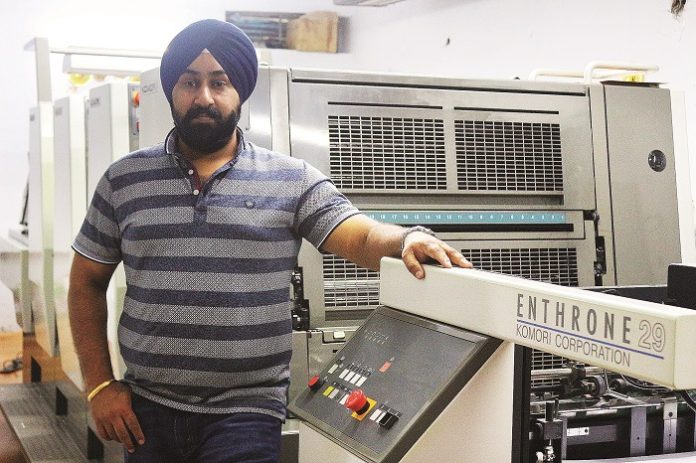

Last year, the company added a 4-color Komori Enthrone 29 sheetfed offset press to its array of existing offset presses. Equipped with autoplate changer, the Enthrone 29 can print a sheet size of 530 x 750 mm on a maximum print area of 520 x 736 mm. “Although the speed of the press is 13,000 sheets per hour, we usually run it at speeds up to 12,000 sheets per hour,” says Singh. According to him, the company has seen 10 to 15% growth in commercial printing and about 30 to 35% growth in packaging since the installation of the Komori Enthrone. Today, commercial printing constitutes 40% of the company’s overall revenue while the remaining 60% comes from packaging.

“The USP of our company is reverse engineering. We continuously study the market for emerging trends and designs in packaging as well as commercial printing. Our team then reverse-engineers the design or trend, tries to figure out how best it can fit into our existing production capabilities, and eventually makes some value additions to produce something new and exciting,” says Singh. The company claims to produce around 40,000 monocartons daily and convert around 200 tons of paper and paper board every month. Singh feels that the market for package printing is changing rapidly with the growth of on-demand production and to survive, one needs to have a sound understanding of the trends and an impeccable focus on quality and price.

“For a commercial printer to move into packaging may sound like a cakewalk, but that is far from what meets the eye. There’s definitely a learning curve and you cannot gain expertise overnight. When we moved to packaging, we were hardly familiar with the nuances of packaging cartons. So we made significant investments in educating and training ourselves by visiting various exhibits. All along, our main thrust has been to invest as wisely as possible so that we buy equipment which can be used both in commercial printing as well as packaging in a rationalized manner. Even today, we look at all possible angles so that our investment brings in maximum ROI. This is the key to survive in a pricesensitive market like India,” Singh quips.

Going forward, Aakar DesignO-Print plans to replace its old 6-color Heidelberg MOS press with a new press for printing metallized effects. The new press will likely be a 20 x 28-inch 6-color Heidelberg, according to Singh. The company also has a 4-color Heidelberg, which runs alongside the Heidelberg MOS. On the prepress front, the company has an Alinte 8e+ violet CtP complemented by a Glunz & Jensen processor. Aakar produces around 150 plates daily, which are from Technova and Fujifilm. The company also has an in-house converting section, powered by a Welbound folder-gluer, as well as lamination, die-cutting and creasing machines.