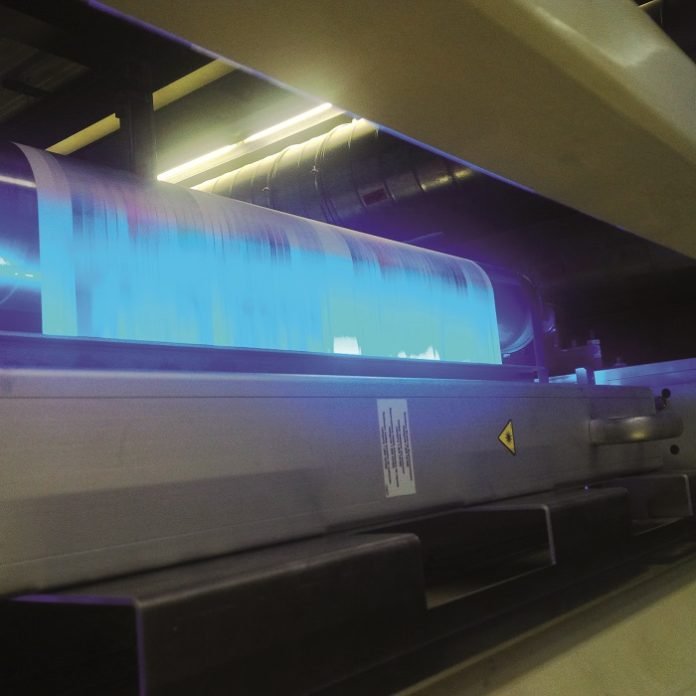

Race tracks provide ideal conditions for testing potential speeds. Similarly, in the world of newspapers, printing presses are the ‘race tracks of the printing industry.’ This is primarily the reason why UV supplier IST Metz used a Wifag OF-7 that puts to test the performance of LED UV technology. The press is located in the production hall of Swiss company Centre d’impression et d’arts graphiques Pressor SA and is equipped with UV curing.

The increasingly widespread nature of LED UV technology in various graphical applications is now piquing interest even in places where this alternative to classic UV curing has barely been used to date. Operators of fast-running web presses looking at investing in LED UV technology are especially keen to understand exactly how a high-performance setup needs to be designed. “An ideal response to this question is resilient information about what printing speeds can actually be achieved in the field using an LED UV system as a function of the combination of printing ink and substrate,” explains Stefan Feil, director – technical marketing at IST Metz.

Experience from the race track promotes safety in traffic

Experience with web printing applications comes primarily from narrow-web label printing to date. In this case, maximum press speed rarely exceeds a value of 200 m/min. There was a general assumption that current performance is significantly higher, but this assumption lacked practical proof. IST Metz saw an opportunity to examine this question in newspaper printing. Centre d’impression et d’arts graphiques Pressor SA (Pressor for short) is a customer of the Nürtingen company and has a printing press equipped with UV technology. The Délemont company produces the regional newspaper Le Quotidien Jurassien and the weekly newspaper La Gazette de la région for publishers Editions D+P SA on this newspaper press, a Wifag OF-7 with a web width of 1,300 mm and a section length of 940 mm.

When the press was installed in 2007, the UV equipment originally consisted of BLK-3-type UV systems from IST Metz. With the rise in the low-energy variant of UV printing, Pressor switched to so-called LE UV technology, in which appropriately adapted printing inks are used in addition to specially doped UV lamps. The simultaneous benefit of this switch was that it was possible to reduce the previous number of three UV units for each side of the web to just one UV unit.

One UV module for each side of the web

For the tests, one of the two LE UV radiators was replaced with an LEDcure system of the LUV 80 type. The choice was a deliberate decision, even though the gap between the radiators and the substrate is 50 mm on this model. In contrast, the more important issue was that the energy is focused on the web by means of the special arrangement of the LEDs in a line.

This accordingly provided separate UV units for the front and back, simultaneously allowing a comparison between low-energy UV and LED UV technology to be made. With systems from IST Metz, the interchange between different UV technologies is made simple by means of the Hot Swap concept. Last autumn at Labelexpo Europe, the company presented the new product concept for the first time. Since it is suitable for sheetfed, web and narrow web printing alike, their drupa 2016 presence also focused on the concept. With the Hot Swap concept, the UV units can be used interchangeably. A simple change from a LAMPcure to an LEDcure system and vice versa is possible. Thus, while the peripheral equipment in the machine remains, a joint electrical supply is used.

Speed incrementally increased

During the test series with LED UV technology, the maximum mechanical speed of the machine was approached incrementally. This speed is 35,000 revolutions an hour, which means a web speed of 9.14 m/s (548 m/min). Start speed was 8,000 revolutions an hour and was increased by 4,000 revolutions an hour after every test. The final test series was the one at 32,000 revolutions an hour—a production speed which Pressor frequently achieves in practice. This corresponds to a web speed of 500 m/min.

Effect of substrate and ink on UV curing

UV curing is affected by a variety of parameters of which the UV system is just one. Other important factors are the material for printing and the printing ink. The obvious choice for the newspaper press was a common 45 gsm newsprint paper. A 70 gsm matt-coated paper quality was tested as a second substrate; this has a more closed surface and thus reduced ink absorption properties. For printing inks, Pressor uses UV printing inks from hubergroup designed for fast-running newspaper printing presses. At drupa, this printingink manufacturer presented a new range of inks for this application, developed especially for the use of LED UV technology. The trials were performed with ‘advance samples’ of the four-color process inks from this new product family.

In summary, the table shows that curing of the inks when printing on newsprint paper was good across all the speeds tested. In this case, density values of 0.90 were specified as color density for yellow, magenta and cyan, with 1.10 specified for black. The test results suggest that with an absorbent paper and low print densities, good curing results may also be achievable beyond the maximum speed of 500 m/min tested.

When printing on absorbent paper qualities, the good depthcuring properties of LED UV curing deliver an additional benefit, as ink which has been absorbed into the paper is reached better than by classic UV radiators. In analogy to classic UV curing, black ink also represents a bigger challenge than the colored ones when LED UV radiators are used. The cause is the same for both types of ink; black pigments absorb more energy from the UV spectrum than color pigments, so this energy is then unavailable for initiating polymerization.

Limits with coated papers and higher ink density

Color densities for the tests using matt-coated paper were at values of 1.30 for yellow, magenta and cyan, and 1.50 for black. Initial signs of incomplete curing were found in the black range, in particular, from a press speed of 28,000 revolutions an hour if assessment followed immediately after printing. In spite of this, it was possible to process the paper web to an acceptable quality in the folding unit. If the result was rated after 24 hours, results at 438 m/min and 500 m/min once again showed good curing.

Suitability of LED UV for high printing speeds

Overall, IST Metz can draw informative conclusions about the current state of the art in LED UV curing from the test results outlined. One is that when printing using LED UV inks, high production rates can now be achieved. Surface speeds such as those usually achieved on presses for narrow-web label printing or in sheetfed offset printing were exceeded by a significant margin in the test runs on the newspaper press. To guarantee reliable curing, however, it should be ensured in cases which require that an appropriately modified speed is selected as a function of the substrate used and of ink density, especially when black ink is involved.